Why Forging Is the Backbone of Modern Engineering

Forging is greater than a legacy process—it’s a modern, performance-driven strategy that besides lengthen influences safety, durability, and effectivity at some stage in industries. In sectors like aerospace, automotive, oil & gas, and defense, forging ensures elements can endure excessive stress, immoderate temperatures, and prolonged company cycles.

As the demand for sustainable and high-performance manufacturing grows, forging stands out for its ability to reduce material waste, enhance part integrity, and deliver consistent quality at scale.

Forged parts aren’t just strong—they’re designed to last, even under the harshest conditions.

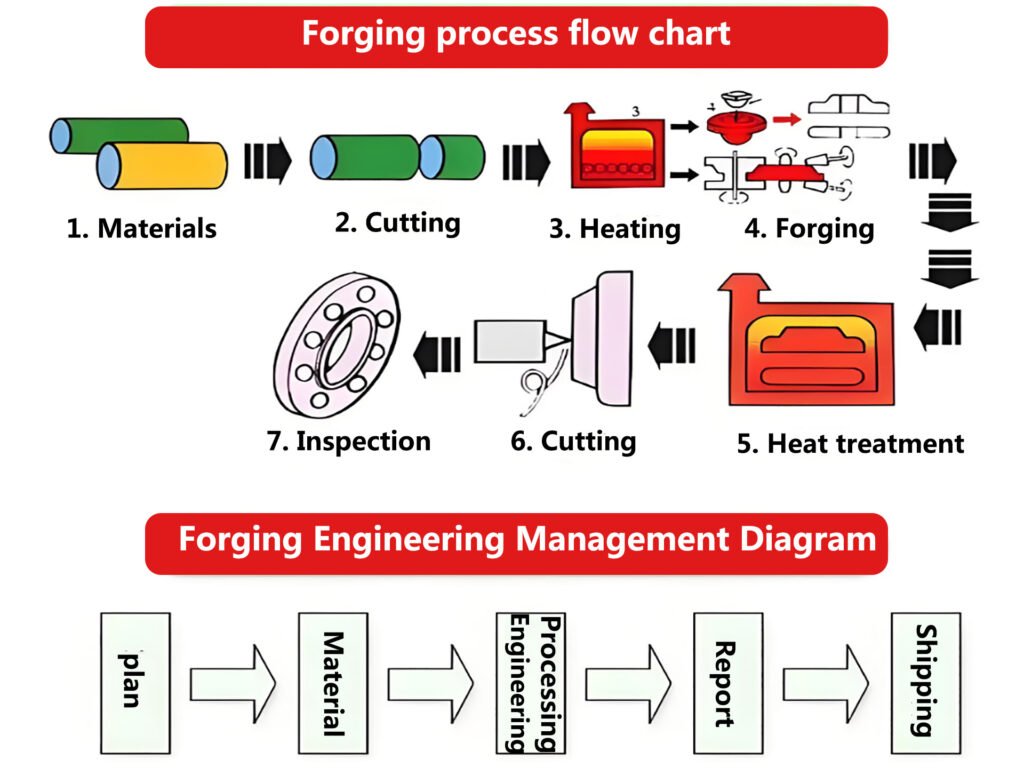

Forging Explained: A Modern Definition

Forging is the process of shaping metal using localized compressive forces, often while the material is heated to increase malleability. It alters the internal grain structure to follow the shape of the part, improving strength, fatigue resistance, and impact tolerance.

Unlike casting (which can introduce porosity and internal voids) or machining (which cuts across grain lines), forging realigns and strengthens the metal’s microstructure.

Forging vs. Casting vs. Machining

| Method | Internal Strength | Cost Efficiency | Ideal Use Cases |

| Forging | High | Medium | Load-bearing, fatigue-prone parts |

| Casting | Low-Medium | High | Complex shapes, lower stress parts |

| Machining | Medium | Low (wasteful) | Precision parts from billet |

Types of Forging Used in Engineering Projects

Open-Die Forging (Hand Forging)

Used for large or custom-shaped parts

Continuous grain flow, fewer inclusions

Typical applications: marine shafts, heavy equipment

Closed-Die Forging (Impression Die)

Dies restrict metal flow for accurate shapes

Suitable for high-volume production

Common in: automotive gears, tools, aircraft parts

Precision Press Forging

Controlled deformation with vertical presses

Tight tolerances, repeatable quality

Used in: robotics, medical instruments, EV components

Isothermal & Hot-Die Forging (Advanced)

Maintains die temperature for difficult alloys

Prevents thermal gradients that can cause cracking

Ideal for: titanium aerospace components

Materials Engineers Should Consider for Forging

Carbon Steel

Affordable and versatile. Suitable for automotive, agriculture, and construction.

Alloy Steel

Enhanced strength, toughness, and wear resistance. Used in mining and power generation.

Stainless Steel

Corrosion resistance with good strength. Common in food processing, energy, and valves.

Titanium & Nickel Alloys

High-performance applications where weight, strength, and temperature resistance are crucial (e.g., jet engines, offshore rigs).

Aluminum Alloys

Lightweight with excellent formability. Ideal for EVs, aircraft structures, and performance bikes.

Advantages of Forging in Modern Engineering

Superior Mechanical Properties

Up to 40% stronger than equivalent cast parts

Withstands shock, vibration, and cyclical stress better

Controlled Grain Flow

Improved fatigue life

Better resistance to impact and wear

Repeatability & Dimensional Stability

Essential for large-scale OEMs

Reduces variation in safety-critical assemblies

Eco-Friendly and Material Efficient

Near-net shape reduces waste

Long lifecycle lowers environmental footprint

Real-World Engineering Sectors Using Forging

| Industry | Common Forged Components | Why Forging Is Used |

| Aerospace | engine discs | Strength-to-weight ratio, reliability |

| Automotive | Crankshafts, connecting rods | Strength, cost-effectiveness, mass production |

| Oil & Gas | Valves, pipeline flanges | Pressure resistance, corrosion protection |

| Energy | Turbine shafts, generator parts | High mechanical and thermal endurance |

| Medical Devices | Orthopedic implants, tools | Biocompatibility, structural integrity |

Hot Forging vs Cold Forging: Which Is Right for Your Application?

Hot Forging

Temperature: 950–1250°C

Pros: Easier shaping, suitable for harder metals

Cons: Surface oxidation, more finishing required

Cold Forging

Temperature: Room temp

Pros: Excellent surface finish, precision tolerances

Cons: Limited to ductile materials, more force needed

The Future of Forging in Engineering

Smart Forging Systems

Integration of sensors, real-time monitoring, and AI-based predictive models ensures tighter control and efficiency.

Digital Simulation & Digital Twins

Simulate material flow, thermal gradients, and die wear before production begins. This reduces trial-and-error costs.

Sustainability Through Forging

Lower scrap rates

Long product lifespans

Increasing use of electric-powered forging presses

FAQ: Engineering Forging Questions Answered

Is forging always stronger than casting?

Yes, due to realigned grain flow and absence of internal voids, forging consistently provides superior mechanical properties.

Can forged components be customized?

Absolutely. Tooling can be tailored for custom geometries, and material selection can be aligned to project-specific requirements.

Conclusion: Why Forging Is an Engineering Power Move

Forging can provide what engineering gurus want most: strength, reliability, and cost-efficiency throughout lengthy working cycles. As industries push for cleaner manufacturing and more suitable products, forging proves to be an integral tool—not a legacy method.

Whether you are designing the subsequent plane engine or constructing high-volume car parts, forging have to be at the coronary heart of your manufacturing plan.

Looking for precision-forged options for your subsequent engineering project? Let’s construct some thing that lasts.