TIPTOP FORGING Manufacturer

With carbon steel, alloy structural steel, carbon steel, alloy tool steel, stainless steel, non-magnetic steel and other raw materials inventory, annual forging capacity of 30,000 tons.We will customize our products and services according to international standards such as API, ASTM, ASME, GOST, NS-1, ISO, GB to meet your needs

Our Forgings Product Range

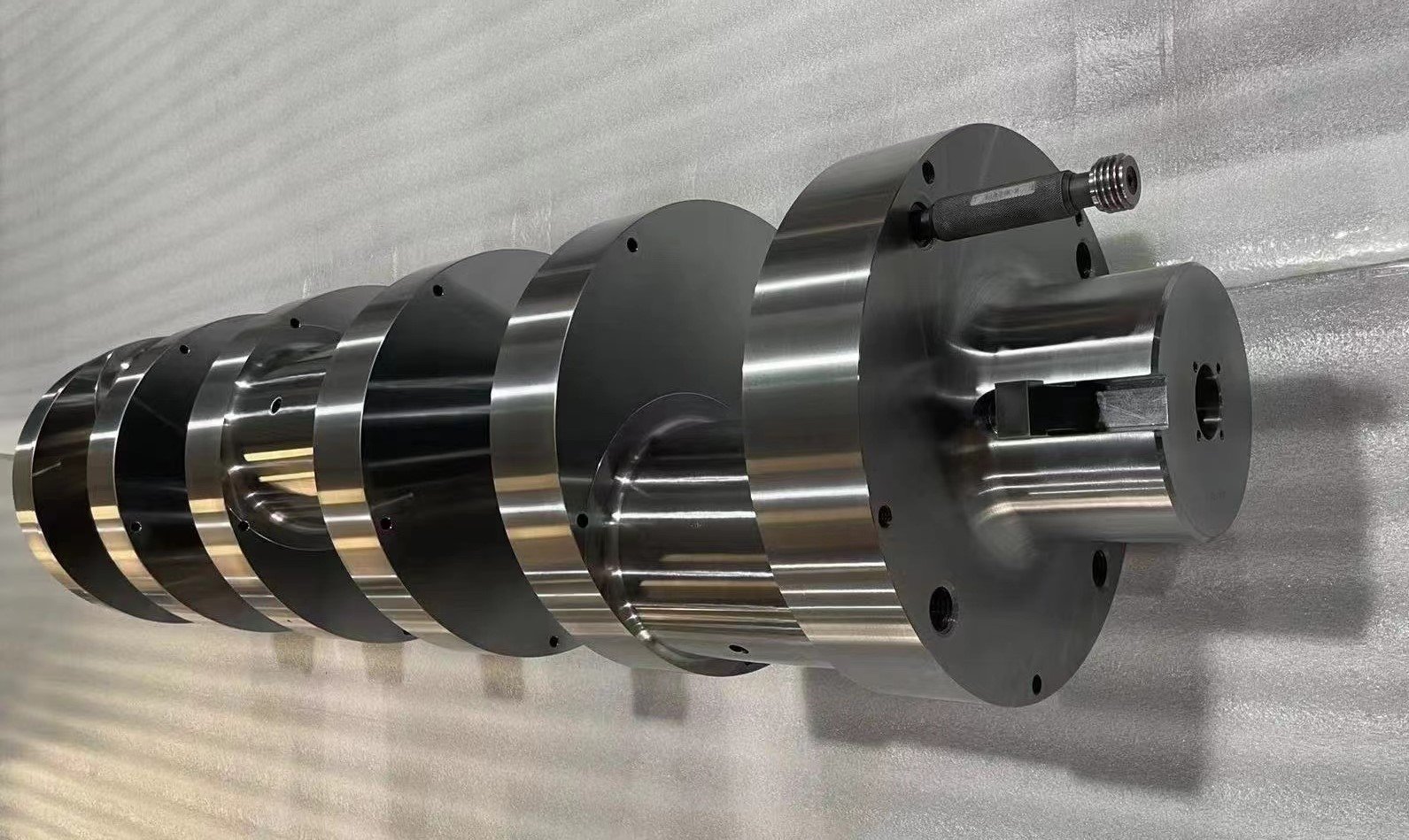

Drill collars, Drill pipe, Stabilizer, Housing , Bars & Subs , Downhole motors

Forged bars: Ideal for oil & gas, providing strength and durability. High-quality forged bars for your projects.

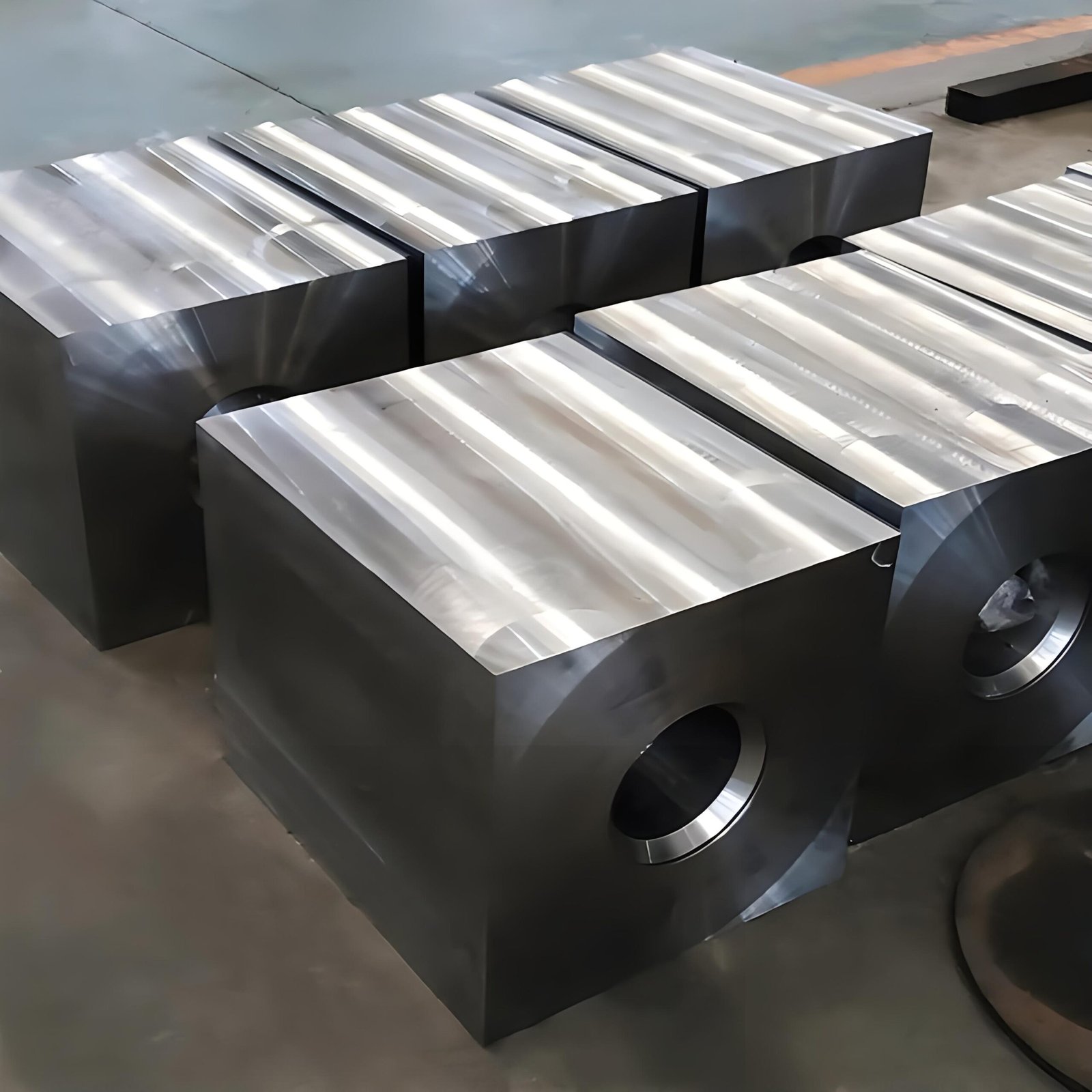

Forged blocks: Used in heavy machinery. Durable forged blocks ensure reliable performance. Choose quality.

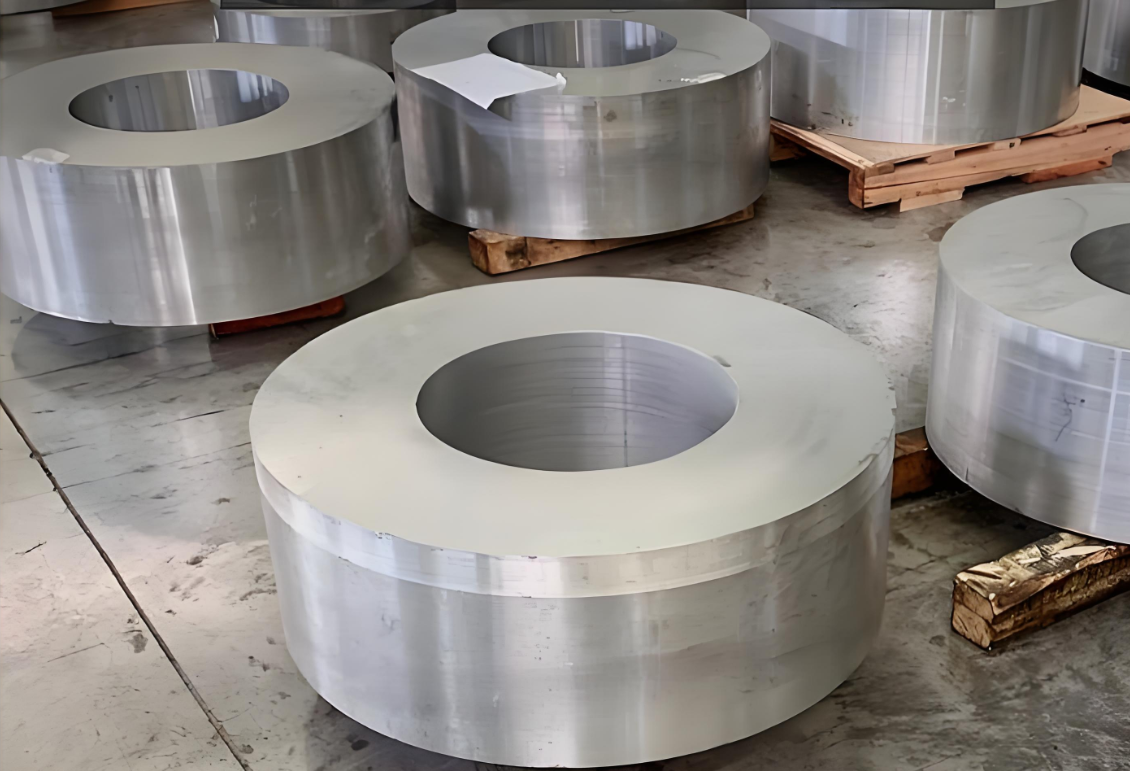

Forged rings: Essential for industrial applications. Precision-forged rings for enhanced functionality.

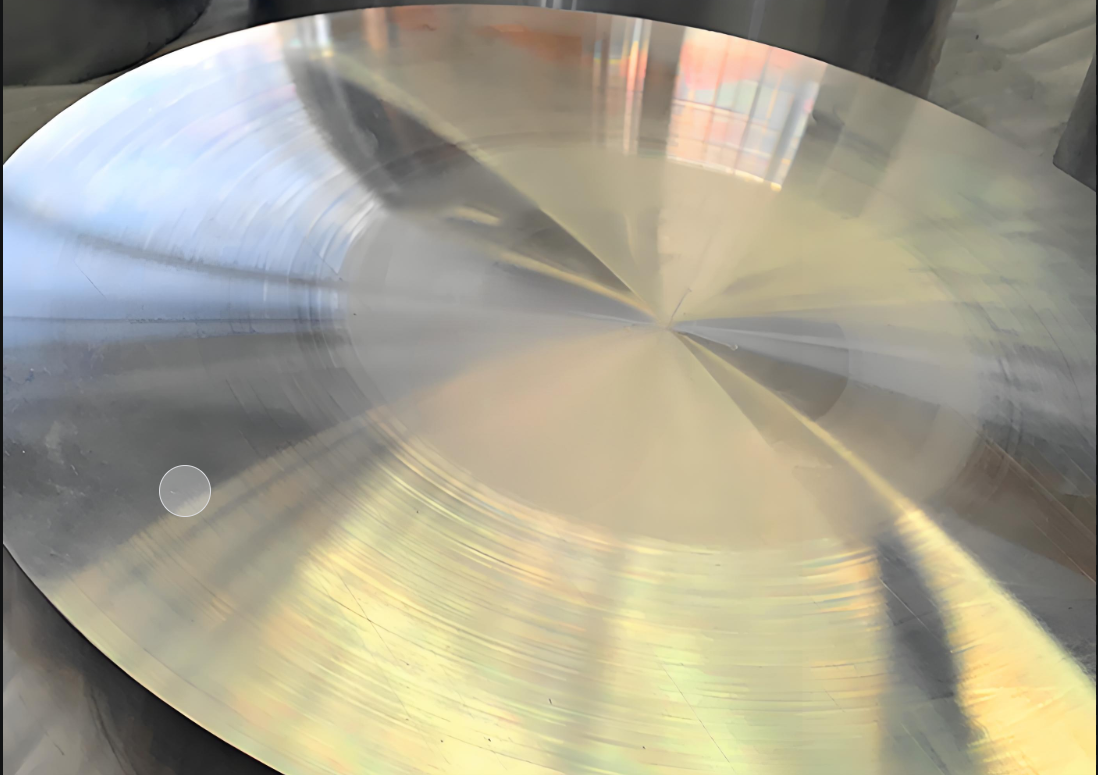

Forged discs : essential for reliable machinery operation in diverse industries.

Production Facilities for Forging Parts

The company is well-equipped,operate China’s largest 16,500-ton open-die press and integrated production line, with one 3500-ton, 4000-ton and 2000-ton free forging hydraulic press, one hydraulic press unit, one 15-ton and 20-ton full hydraulic operating machine, one 3-ton electro-hydraulic hammer, one 3-ton operating machine, three trolley-type heating furnaces, two trolley-type annealing furnaces, one horizontal cooling pool and more than 20 large and medium-sized lathes (including deep hole drilling, boring machines, CNC lathes, two machining centers and one grinder), which can help you achieve precision forming of complex forgings, reduce machining allowances, improve material utilization and reduce subsequent processing costs.

Quality Control Process for Forging Parts

Before product release,we conduct comprehensive quality inspections, including hardness testing, flaw detection, and mechanical properties testing.

This ensures each product meets standards in performance and quality, giving customers confidence in our products.

Thread detector

- Accurately measure thread parameters

- Automatically determines thread integrity

spectrograph

- Accurate testing of raw material composition

- Dynamic monitoring of production process

- Finished product quality conformance verification

Carbon sulfur analyzer

- Precise control of material composition

- Optimize the smelting and forging process

- Quality traceability and standardization certification

Universal testing machine

- multi-dimensional mechanical properties test

- High temperature and high pressure environment simulation

- Precision control and data acquisition

Nondestructive testing

- Defect detection and location

- Material performance evaluation

- Geometric parameter measurement

- Dynamic monitoring and prediction

Metallographic microscope

- Analysis of microstructure

- Defect and contamination detection

- Whole process data support

Customized Forging Services

- Our advanced forging technology can create unique products, parts and shapes for a variety of industries and applications.

- With more than two decades of experience, we have the knowledge and expertise to manufacture custom forgings to the exact specifications of your project.

- TIPTOP also offers a variety of additional services to enhance the quality and value of your FORGING

Covering the complete technology chain of material selection, process simulation and finished product inspection, we provide a quality assurance system based on international standards such as ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 to ensure the reliability of products from development to delivery

Equipped with an experienced team of engineers to support the optimization of forging solutions under complex working conditions (such as high temperature/pressure/corrosion environment)

Meet the stringent requirements of the oil/gas, nuclear and other industries

For wind power/nuclear power and other special scenarios, the development of salt spray corrosion resistance, high temperature resistance and other special alloy forging solutions

WHO WE ARE

High-Quality Forging Manufaturer For Global Industries

TIPTOP Forging is a modern high-tech enterprise with strong technical force, complete production equipment and strict testing facilities, which is mainly engaged in the research and development, production, sales and service of all kinds of large and medium sized forgings including shafts, metallugical rollers, pipe moulds,φl50-800 round bars, hollow bars,steel blocks, turbine shafts, 4145H mod stabilizer forgings and non-magnetic drill collar forgings, irregular forgings, etc..

Forgings Delivery Site

Tiptop can ensure that your goods are of qualified quality, accurate specifications and well packed when shipped, ensuring on-time delivery and meeting customer requirements.

Sufficient Inventory Enables Fast Delivery

Relying on our strong supply chain management capabilities and forward-looking production planning, our company always maintains an adequate inventory of raw materials and semi-finished products to ensure the efficient delivery of forged parts.

OUR CUSTOMERS

OUR ISO CERTIFICATES

As an ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certified forging manufacturer, we embody global standards in quality precision, sustainable operations, and workplace safety.

TIPTOP Core Strengths of Forgings

Technical Force

From raw materials, forging process,heat treatment, machining, etc., we have experts to provide strong technical support. In addition to industry standard products,we provide customization and R&D services.

Quality Assurance

Each product undergoes strict quality testing, we accept any third party inspection and each product can be supplied with prolonged or separate test coupon for customer to recheck.

Integrated Supply Service

Long-term cooperation with high- quality raw material mills & stockists to ensures efficient material supply.Close cooperation with API machine shops, can support finished products supply.

TIPTOP FORGING

Metallic Materials Used in Forging

Carbon Steel

Carbon steel is a kind of steel with a high carbon content, usually has good strength and hardness, and is suitable for forging. Oil and energy equipment, such as drilling components, pressure vessels, pipe flanges

Alloy Steel

Alloy steel forgings are widely used in aerospace, petroleum energy and other fields, such as turbine disks and downhole tools, which belong to high-temperature and high-pressure environments.

Stainless steel

Stainless steel forgings are used more in mechanical equipment, metallurgy, chemical industry and other fields, such as gears, shafts, flanges and so on

Copper Alloys

Copper alloy materials are used in different industries, such as hydraulic systems, aerospace, Marine engineering, etc

Aluminum Alloys

Aluminum alloy used in the field of aerospace shipbuilding, mentioned Marine engine parts, hull forging parts, such as crankshaft, mast and so on

Nickel Alloys

Used in aerospace, nuclear energy, petrochemical and other fields of specific forging parts, such as cylinder, flange, roll, turbine blade, reaction vessel, etc

Our Services for Custom Forgings

Vestibulum integer ligula parturient commodo convallis porta viverra dis primis.

Forging parts are used in the oil industry for oil well drilling, refining, transportation and other links

Forging parts are used in the mining industry mining equipment. Beneficiation and transportation equipment. Energy mining equipment

Forging has a pillar role in aerospace and is used for key engine components. Fuselage structure parts. Spacecraft parts, etc

FAQ

AISI 4145: High fatigue resistance (drilling, high-temperature).

AISI 4330V: Dynamic loads with toughness/weldability (aerospace).

AISI 4340: Maximum strength in heavy-load parts (gears, shafts).

Forging: Using methods such as hammering to turn metal materials in a plastic state into workpieces with certain shapes and sizes, and altering their physical properties.

Casting: A processing method in which molten metal is poured into a mold, and after cooling, solidifying, and cleaning, the required shaped castings are obtained. It can be used to manufacture various objects with complex shapes.

- Independent design mold opening capability :

support the whole process design from drawings to finished products, covering complex geometric shapes such as special-shaped structure and porous position, reducing secondary processing costs

- Vertical integration industry chain :

From raw material processing (such as steel plate pretreatment) to system integration and whole machine testing, the whole chain independent manufacturing reduces the cost of intermediate links and ensures quality control

- Whole process quality inspection:

From raw material testing (such as metal composition analysis) to third party certification of finished products (such as ultrasonic inspection, hardness testing), ensure that compressive strength, fatigue life and other indicators meet the standards

BLOG

Explore More Information About The Forging!

Large Industrial Forged Rings for Heavy-Duty Applications

Large industrial forged rings are essential components in heavy-duty mechanical systems where strength, dimensional stability, and long-term reliability are critical. Compared with fabricated or cast alternatives, forged rings provide a seamless structure and refined grain flow, allowing them to perform reliably under high loads, cyclic stress, and demanding operating conditions. For industries such as energy, mining, marine engineering, and heavy machinery, forged rings remain a proven and trusted solution.