AISI 1141

It is a medium-carbon, resulfurized "free-machining" steel commonly used in forged components due to its balance of strength, machinability, and cost-effectiveness. It belongs to the 1100 series of steels, characterized by higher sulfur content for improved machining performance.

Descriptions

1. Chemical Composition

AISI 1141 complies with the following chemical composition (weight %):

| Element | Composition (%) |

| Carbon (C) | 0.38-0.45 |

| Manganese (Mn) | 1.35-1.65 |

| Phosphorus (P) | ≤0.040 |

| Sulfur (S) | 0.08-0.13 |

| Iron (Fe) | Balance |

2. Mechanical Properties

Mechanical properties vary with heat treatment and forging processes. Typical values for hot-forged and normalized AISI 1141 components include:

| Property | Value |

| Tensile Strength | 620-795 MPa (90-115 ksi) |

| Yield Strength | 415-585 MPa(60-85 ksi) |

| Elongation (50mm) | 15-25% |

| Reduction of Area | 35-50% |

| Hardness | 180-250 HB (Brinell) |

| Impact Energy (Charpy V-notch) | 20-35 J(15-25 ft-1b) |

3. Key Advantages

Superior machinability due to sulfur inclusion.

Good wear resistance and fatigue strength.

Cost-effective for high-volume production.

4. Limitations

Reduced weldability (avoid welding unless using specialized techniques).

Lower ductility compared to low-sulfur steels (e.g., AISI 1045).

Recent products

API 8C 4145H Top Drive Main Shaft Forging

Heavy-Duty Gas Turbine Forged Disc

Nuclear Power Head Plate Forging

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Standards & Certifications

ASTM A29/A29M (Standard Specification for Steel Bars, Carbon and Alloy).

SAE J403 (Chemical Composition of SAE Carbon Steels)

Applications

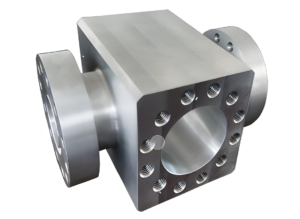

a. Drilling Equipment

Tool Joints and Drill String Adapters:

High machinability allows rapid production of threaded connections. Sulfur inclusions reduce tool wear during mass production.Mud Pump Liners and Pistons:

Moderate wear resistance and ease of machining suit components exposed to abrasive drilling fluids.

b. Valve Components

Valve Stems and Bushings:

Precision-machined parts requiring smooth surfaces and dimensional accuracy.

c. Surface Hardware

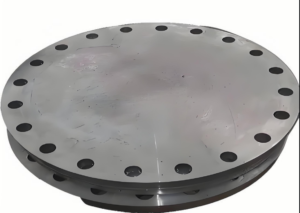

Bolts, Studs, and Fasteners:

High-volume production of standardized fasteners for rig assembly and pipeline flanges.

d. Hydraulic Systems

Cylinder Rods and Actuator Parts:

Used in low-to-medium pressure systems where strength and machinability outweigh corrosion concerns.

a. Material Handling Systems

Conveyor Chain Links and Sprockets:

High tensile strength and machinability support rapid production of replacement parts.Shafts for Crushers and Screens:

Moderate load-bearing capacity suits secondary crushing equipment.

b. Wear Parts

Bucket Teeth and Adapters:

Surface-hardened AISI 1141 forgings (via induction hardening) for excavators and loaders.Hammer Mill Pins:

Cost-effective solution for replaceable impact components.

c. Drilling Tools

Rock Drill Bushings and Collars:

Machined to tight tolerances for percussive drilling equipment.

d. Support Structures

Brackets and Mounting Plates:

Non-critical structural parts requiring minimal post-forging machining.

Automotive: Axles, gears, shafts, and connecting rods.

Industrial Machinery: Bolts, studs, hydraulic components, and spindles.

Agriculture: Wear-resistant parts, tillage tools, and drivetrain components.

Construction: Fasteners, brackets, and forged fittings.