ASTM A572

It is widely used in forged components for demanding structural and industrial applications.

Descriptions

1. Chemical Composition

ASTM A572 is classified into five grades (42, 50, 55, 60, 65), with Grade 50 being the most common for forgings. The chemical composition (weight %) varies slightly by grade but generally adheres to the following ranges for Grade 50:

| Element | Content (%) |

| Carbon (C) | ≤0.23 |

| Manganese (Mn) | 1.35-1.65 |

| Phosphorus (P) | ≤0.040 |

| Sulfur (S) | ≤0.050 |

| Silicon (Si) | 0.15-0.40 |

| Vanadium (V) | 0.01-0.15 |

| Columbium (Nb) | 0.005-0.05 |

| Iron (Fe) | Balance |

2. Mechanical Properties

Mechanical properties depend on the grade and heat treatment. For Grade 50 hot-forged components:

| Property | Value |

| Tensile Strength | 448-552 MPa(65-80 ksi) |

| Yield Strength | 345 MPa(50 ksi) |

| Elongation (200mm) | 18-21% |

| Hardness | 130-180 HB(Brinell) |

| Impact Energy (Charpy V-notch) | 27-34J(20-25 ft-1b) at -18°C (0°F) |

3. Key Advantages

High Strength: Outperforms ASTM A36 in yield and tensile strength.

Lightweight Design: Reduces material usage while maintaining structural integrity.

Weather Resistance: Superior corrosion resistance compared to plain carbon steels.

Weldability: Compatible with common welding techniques (e.g., shielded metal arc welding).

4. Limitations

Cost: Higher than carbon steels due to alloying elements.

Complex Heat Treatment: Higher grades (e.g., 65) require precise Q&T processes.

Machinability: Lower than free-machining steels (e.g., 12L14) due to alloy content.

Recent products

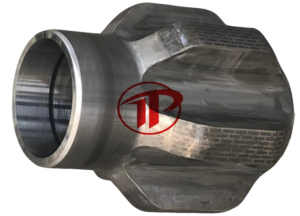

API7-1 4145H Stabilizer Sleeve Forging

7050 2024 Aerospace Aluminum Forging

API 6A 4130 4140 Casing Head Forging

Aerospace Aluminum Forging Solutions

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Standards & Certifications

ASTM A572/A572M: Standard specification for HSLA structural steel.

ASTM A788: Standard for steel forgings, general requirements.

ASME SA-572: Pressure vessel and boiler applications.

Applications

a. Drilling & Wellhead Equipment

Drill Collars and Tool Joints:

High yield strength withstands torsional and axial stresses during deep drilling operations.Blowout Preventer (BOP) Components:

Forged flanges, housings, and connectors for high-pressure well control systems.

b. Pipeline & Pressure Systems

Pipeline Flanges and Fittings:

Used in high-pressure transmission lines for oil, gas, and CO₂.Valve Bodies and Bonnets:

Critical for pressure-retaining systems in refineries and offshore platforms.

c. Structural Components

Offshore Platform Legs and Jacket Braces:

Lightweight forgings reduce structural weight while maintaining strength in corrosive marine environments (with coatings).Crane Booms and Lifting Equipment:

High strength-to-weight ratio supports heavy lifting operations.

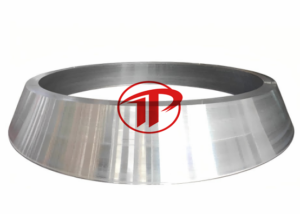

a. Material Handling & Transport

Crusher and Mill Shafts:

High torsional strength for ore processing equipment.Conveyor Drive Drums and Rollers:

Durable forgings for bulk material transport systems.

b. Earthmoving Equipment

Excavator Bucket Linkages and Pins:

Resists cyclic loading and abrasion in rock and soil excavation.Dump Truck Chassis Components:

Forged frames and suspension parts for heavy-duty haul trucks.

c. Support Infrastructure

Mine Shaft Support Beams:

Structural forgings for underground tunnel reinforcement.Vibrating Screen Frames:

High fatigue resistance for screening equipment in mineral processing.

Infrastructure: Bridge girders, transmission towers, and crane booms.

Construction: Heavy-duty brackets, anchor bolts, and base plates.

Transportation: Truck frames, trailer axles, and railcar components.

Energy: Wind turbine hubs, drilling equipment, and offshore platform fittings