AISI 1008/1010

AISI 1008 and 1010 are low-carbon steels widely used for forgings due to their excellent formability, weldability, and cost-effectiveness.

Descriptions

1. Chemical Composition

The chemical compositions of AISI 1008 and 1010 (per ASTM A29/A29M and SAE J403 standards) are:

| Element | AISI1008 | AISI 1010 |

| Carbon(C) | 0.08%max | 0.08-0.13% |

| Manganese (Mn) | 0.30-0.50% | 0.30-0.60% |

| Phosphorus (P) | 0.040% max | 0.040% max |

| Sulfur (S) | 0.050% max | 0.050% max |

| Iron (Fe) | Balance (~99.4%) | Balance(~99.3%) |

Typical mechanical properties for AISI 1008/1010 forgings (annealed or cold-worked condition):

| Property | AISI1008 | AISI 1010 |

| Tensile Strength | 295-345 MPa(43-50 ksi) | 325-380 MPa (47-55 ksi) |

| Yield Strength(0.2%) | 170-205 MPa(25-30 ksi) | 210-285 MPa (30-41 ksi) |

| Elongation (50mm) | 20-30% | 15-25% |

| Hardness (Brinell) | 95-120 HB | 105-130 HB |

| Modulus of Elasticity | 200 GPa (29,000 ksi) | 200 GPa(29,000 ksi) |

| Density | 7.87 g/cm³ | 7.87 g/cm³ |

3. Key Advantages

Low cost: Economical for high-volume production.

Ease of fabrication: Excellent weldability and machinability.

Surface finish: Suitable for plating, painting, or galvanizing.

4. Limitations

Low strength: Not suitable for high-stress applications (e.g., aerospace).

Corrosion susceptibility: Requires coatings for outdoor or corrosive environments.

5. Comparison of AISI 1008 vs. 1010

| Aspect | AISI1008 | AISI 1010 |

| Carbon Content | Lower (0.08% max) →Softer,more ductile | Slightly higher (0.08-0.13%)→Stronger |

| Typical Use | Non-critical parts (e.g., fasteners) | Parts requiring moderate strength (e.g.,shafts) |

Recent products

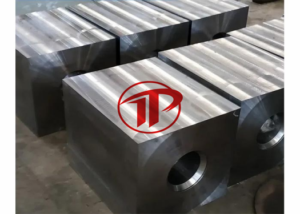

42CrMo4 Large Alloy Steel Forged Block For Hot Forging Mould

Aerospace Spacecraft Interior Components

Gear shaft Forging

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Pipeline Components: Flanges, pipe connectors, and valve bodies for low-pressure systems. Support brackets and clamps for piping networks. Drilling Equipment: Non-load-bearing parts (e.g., tool handles, housing covers). Temporary scaffolding and work platforms.

Material Handling Systems: Conveyor chain links, rollers, and brackets. Hopper liners and chute components (non-abrasive zones). Support Structures: Bolts, pins, and fasteners for temporary structures. Lightweight frames for ventilation ducts. Equipment Maintenance: Replacement parts for low-wear machinery (e.g., hinge pins, spacers).

Brackets and mounting plates for turbines (non-rotational parts). Cable trays and conduit supports in power plants.

Ground Support Equipment: Tooling jigs, workbenches, and maintenance carts. Non-critical fasteners for hangar structures. Aircraft Interiors: Seat adjustment mechanisms (non-structural parts). Overhead bin latches and handles. Prototyping: Low-cost test components for design validation.