AISI 4330V

It is widely used in applications requiring exceptional strength-to-weight ratios and reliability under extreme stress, such as aerospace, oil and gas, and heavy machinery. The "V" designation indicates vanadium addition, which refines grain structure and improves mechanical properties.

Descriptions

1. Chemical Composition

AISI 4330V combines chromium, molybdenum, nickel, and vanadium for superior strength and toughness. Vanadium enhances grain refinement and resistance to creep and fatigue.

| Element | Composition(% by Weight) | Role |

| Carbon (C) | 0.28-0.33 | Increases strength and hardness. |

| Manganese (Mn) | 0.40-0.70 | Improves hardenability and deoxidizes steel. |

| Silicon (Si) | 0.15-0.35 | Strengthens ferite and improves cleanliness. |

| Nickel (Ni) | 1.65-2.00 | Enhances core toughness and impact resistance. |

| Chromium (Cr) | 0.70-0.90 | Boosts hardenability and wear resistance. |

| Molybdenum (Mo) | 0.20-0.30 | Increases strength and creep resistance. |

| Vanadium (V) | 0.05-0.10 | Refines grain structure, improves fatigue strength. |

| Phosphorus (P) | 0.025 max | Controlled impurity (minimizes brittleness). |

| Sulfur (S) | 0.025 max | Controlled impurity (limits segregation). |

| Iron (Fe) | Balance | Base metal. |

2. Mechanical Properties

AISI 4330V forgings achieve optimal performance through heat treatment (e.g., quenching and tempering). Properties vary based on processing methods.

| Property | Normalized | Quenched &Tempered | As-Forged | Test Standard |

| Tensile Strength | 760-930 MPa | 930-1080 MPa | 620-800 MPa | ASTM E8 |

| Yield Strength(0.2%offset) | 585-760 MPa | 830-950 MPa | 415-620MPa | ASTME8 |

| Elongation (% in 50 mm) | 18-22% | 12-18% | 15-20% | ASTME8 |

| Reduction of Area | 50-60% | 45-55% | 40-50% | ASTME8 |

| Hardness (Brinell) | 220-260HB | 285-341HB | 190-230HB | ASTME10 |

| Impact Toughness(Charpy V) | 50-80J(room temp) | 40-60J | 60-90J | ASTME23 |

| Fracture Toughness(K<sub>IC</sub>) | 120-150MPa√m | 90-120 MPa/m | N/A | ASTME399 |

3. Key Advantages

Superior Toughness: Vanadium addition ensures exceptional fracture resistance.

High Strength-to-Weight Ratio: Ideal for aerospace and defense applications.

Fatigue and Crack Resistance: Performs well under cyclic and dynamic loads.

Heat Treatability: Tailored properties via quenching, tempering, or normalizing.

4. Typical Fofging Product

Forged Landing Gear Beams

High-Pressure Drill Collars

Turbine Rotor Shafts

Heavy-Duty Crankshafts

Armor Vehicle Axles

Recent products

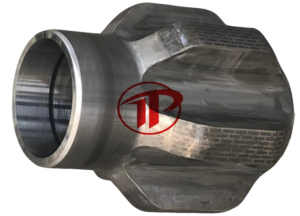

API7-1 4145H Stabilizer Sleeve Forging

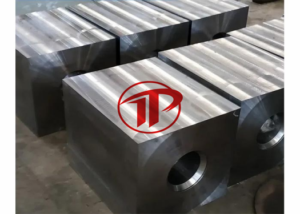

Drill Bit Forging

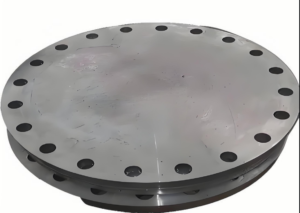

Heavy-Duty Gas Turbine Forged Disc

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Landing gear components, turbine shafts, engine mounts.

Turbine rotors, high-pressure valve bodies.

Drill collars, blowout preventers (BOPs), subsea connectors.

Crankshafts, gears, mining equipment shafts.