Description

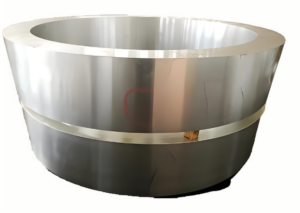

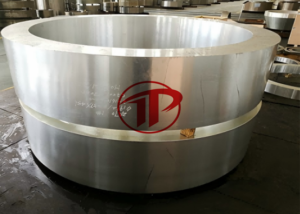

Introduction to sleeve Quill forging for top drive systems

The sleeve/spindle is a key component of the top drive drilling system and is made of AISI 4330V or AISI 4340 steel.

Its main functions are as follows(Belongs to the shaft category):

1. Quill Forging Power and torque transmission

Power transmission: The sleeve is directly connected to the drive motor (electric or hydraulic) of the top drive and transmits the rotational power to the drill string (drill pipe and bottom hole assembly) to rotate the drill bit for drilling.

High torque handling: It can withstand high torque loads in complex formations (such as hard rock or viscous areas) to ensure stable power transmission.

2. Quill ForgingAxial movement and drilling control

Axial movement: The sleeve can be retracted vertically, allowing the top drive to control the weight on bit (WOB) while rotating the drill string, thereby achieving precise drilling speed adjustment.

Automation: Integrated with the top drive control system, the axial movement of the gooseneck is automated to optimize efficiency and reduce human errors.

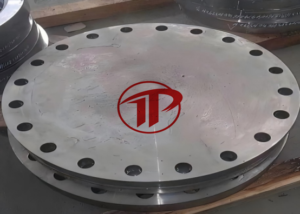

3. Quill Forging Connection and sealing

Drill string connection: The lower end of the gooseneck is connected to the drill pipe (or short section) through threads or quick connectors to achieve reliable power transmission.

High-pressure seal: Internal seals prevent drilling fluid (mud) from penetrating the top drive, protecting the motor and gearbox from corrosion.

4. Sensor integration and data monitoring

Real-time data: Sensors on the gooseneck monitor torque, speed, and axial load to help drillers assess downhole conditions (such as drill bit wear or formation changes).

Safety alarm: Abnormal torque or vibration triggers an emergency shutdown to prevent equipment damage or wellbore accidents.

5. Complex working condition handling

Stuck drill recovery: The gooseneck assists in rescuing the stuck drill by reverse torque or applying vibration.

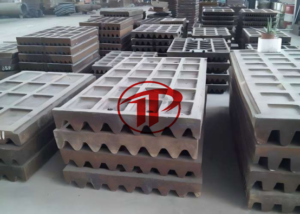

TIPTOP can manufacture forged gooseneck according to the provided drawings!

Reviews

There are no reviews yet.