When it comes to industrial forging, deciding on the right forge bar is one of the most necessary choices engineers and procurement managers should make. Whether you are manufacturing factors for oil & gas, energy generation, automotive, mining, or heavy machinery, the houses of the forge bar you pick will immediately affect performance, safety, and cost-efficiency.

In this guide, we’ll stroll you via the whole lot you want to comprehend about forge bar selection—including cloth types, mechanical properties, and real-world applications.

What Is a Forge Bar?

A forge bar is a strong metallic bar used as uncooked inventory for forging tactics such as open die forging, closed die forging, or ring rolling. These bars are normally made of carbon steel, alloy steel, stainless steel, aluminum, nickel, or titanium, and are cautiously chosen primarily based on the needs of the application.

Forge bars are commonly used to produce:

Shafts

API 8C 4145H Top Drive Main Shaft Forging

The top drive main shaft is the core transmission component of the oil drilling top drive system (Top Drive).

Gears

Gear Shaft Forging – Precision Forged Shafts for Heavy-Duty Applications

Gear Shaft Forging is the necessary intermediate factor for manufacturing high-strength, precision-engineered shafts used in annoying industrial applications. Through superior forging techniques, these shafts attain a most appropriate grain float and mechanical integrity, making sure dependable overall performance below excessive torque, shock loads, and cyclic fatigue.

Flanges

Dual-flange Spacer Spool Forging – Precision Engineered for High-Pressure Applications

Dual-flange Spacer Spool Forging is a fundamental aspect used to join sections of a wellhead or pipeline machine the place specific spacing, alignment, and sealing are essential. Designed for high-pressure oil and gasoline operations, these forgings make certain safe, leak-proof connections whilst supplying extraordinary power and durability.

Cylinders

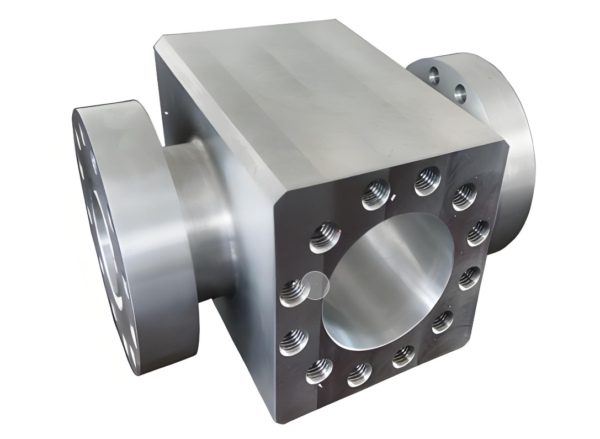

Forged Cylinder Blocks – Strong, Reliable, and Built to Last

Forged Cylinder Blocks are precision-forged metallic factors designed for heavy-duty equipment. Compared to forged or welded alternatives, they provide greatest strength, durability, and reliability — making them perfect for oil & gas, construction, marine, and energy technology industries.

Forged rings

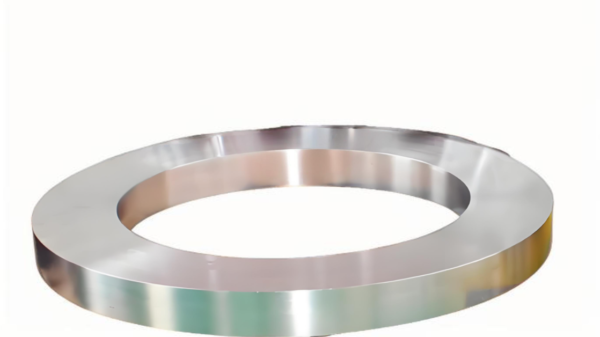

Aluminum Forged Rings for Aerospace & More

We offer a wide range of high-performance aluminum alloy forged rings, including:

6061 – general purpose, excellent weldability and corrosion resistance

7075 – High-strength aerospace alloy with excellent fatigue properties

2024 – Excellent machinability and toughness, ideal for aerospace components

7050 – Corrosion-resistant, high-stress-resistant aerospace-grade alloy

Structural components

They come in round, square, flat, or custom cross-sectional shapes, depending on the requirements of the forged product.

Why Forge Bar Selection Matters in Industrial Applications

The forge bar you choose will dictate the mechanical properties of the final forged component. Poor material selection can result in:

Cracking or premature failure

Reduced fatigue life

Insufficient strength or toughness

Machining difficulties

Higher total cost of ownership

Industries such as aerospace, oil & gas, and energy require forgings that can endure extreme temperatures, high stress, corrosion, and dynamic loading. Choosing the wrong forge bar can have catastrophic consequences in such critical environments.

Common Materials Used for Forge Bars

Carbon Steel Forge Bars

Ideal for general-purpose industrial parts. Common grades include:

ASTM A105

1020 / 1045

✔ Cost-effective

✔ Good machinability

✔ Moderate strength

Alloy Steel Forge Bars

Used in high-strength or heat-treated applications:

4140 forge bar – popular for its balance of strength and toughness

4340, 8620, 52100

✔ High tensile strength

✔ Great impact resistance

✔ Used in oilfield, automotive, and heavy-duty parts

Stainless Steel Forge Bars

Perfect for corrosive environments:

304, 316L, 410, 17-4PH

✔ Excellent corrosion resistance

✔ High-temperature durability

✔ Common in chemical plants, marine applications, and food processing

Specialty Metals

Titanium forge bars – lightweight, corrosion-resistant, used in aerospace

Aluminum forge bars – lightweight and machinable for structural components

Nickel-based forge bars – ideal for high-temperature or corrosive settings (e.g., Inconel 718)

How to Select the Right Forge Bar for Your Application

When choosing a forge bar, consider the following:

1. Operating Conditions

Temperature

Pressure

Corrosive environment

Load cycles

2. Mechanical Requirements

Tensile strength

Yield strength

Hardness

Toughness

Fatigue resistance

3. Machinability & Weldability

Some materials are easier to machine or weld than others. For example, 4140 is easier to machine than Inconel.

4. four Industry Standards & Certification

Ensure your forge bar dealer gives substances that comply with ASTM, ASME, API, ISO, or customer-specific standards.

Applications That Rely on Precision Forge Bar Selection

Forge bars are used across a wide variety of sectors:

Oil & Gas: Drill collars, subs, valves

Aerospace: Landing gear components, structural brackets

Power Generation: Turbine shafts, rotors

Automotive: Gears, axles, drive shafts

Heavy Equipment: Rollers, cranes, mining tools

Each application demands specific performance characteristics from the forge bar.

Why Source Forge Bars from Tiptop Forging?

As a trusted forge bar manufacturer in China, Tiptop Forging provides:

Customized forge bar solutions in carbon, alloy, stainless, titanium, and aluminum

Heat-treated and rough/finish machined bars

Strict quality control, with full MTCs and traceability

Competitive pricing and international shipping

Technical consulting to help you select the best material

Whether you need 4140 forge bars for downhole tools or stainless steel forge bars for food-grade components, we have the expertise and inventory to deliver.