Pressure vessels are vital factors in a large vary of industries, from chemical processing to electricity production. Choosing the proper vessel now not solely ensures operational effectivity however additionally immediately affects safety, compliance, and long-term cost-effectiveness. This information will stroll you thru key issues and reply vital questions customers regularly search for when deciding on stress vessels.

What Is a Pressure Vessels?

A pressure vessel is a closed container specifically designed to hold gases or liquids at a pressure substantially higher or lower than the ambient pressure. These vessels are engineered to cope with excessive stipulations and are built in accordance to stringent graph codes such as the ASME requirements for strain vessels.

In easier terms, a strain vessel definition refers to any container that safely holds pressurized content. The that means of a stress vessel extends past storage—it consists of safety-critical tools for processing, heating, and separation functions.

What Constitutes a Pressure Vessel?

You may also wonder, what constitutes a stress vessel beneath engineering and regulatory guidelines? Typically, the following points apply:

The pressure vessels operates above 15 psi (as described by means of ASME).

It has sealed or partly sealed boundaries.

It undergoes strict checking out such as hydrostatic or radiographic inspection.

It is constructed from substances rated for pressure, temperature, and corrosion conditions.

Failure to understand these requirements can also lead to non-compliance, posing serious security dangers in industrial settings.

Understanding the Pressure in a Vessels

Pressure in a vessel isn’t always simply about inner PSI—it displays the forces that have an impact on each section of the system:

Design pressure: The most stress the vessel is constructed to withstand.

Working pressure: The everyday running strain in the course of use.

Burst pressure: The stage at which failure may occur.

For corrosive or high-pressure environments, stainless steel pressure vesselsmost reliable overall performance and structural integrity. Choosing the proper stress ranking is fundamental for tools toughness and place of business safety.

Common Types of Pressure Vessels

Different functions name for one of a kind sorts of strain vessels. Here are the most regularly used ones:

Storage vessels – for preserving uncooked gases, liquids, or chemicals.

Process vessels – such as reactors and separators used in chemical manufacturing.

Heat exchangers – which switch warmness between fluids.

Horizontal and vertical vessels – chosen based totally on set up footprint.

When cleanliness, corrosion resistance, and sanitation are integral (such as in meals or pharma), ss pressure vessels (made from 304/316 stainless steel) are commonly preferred.

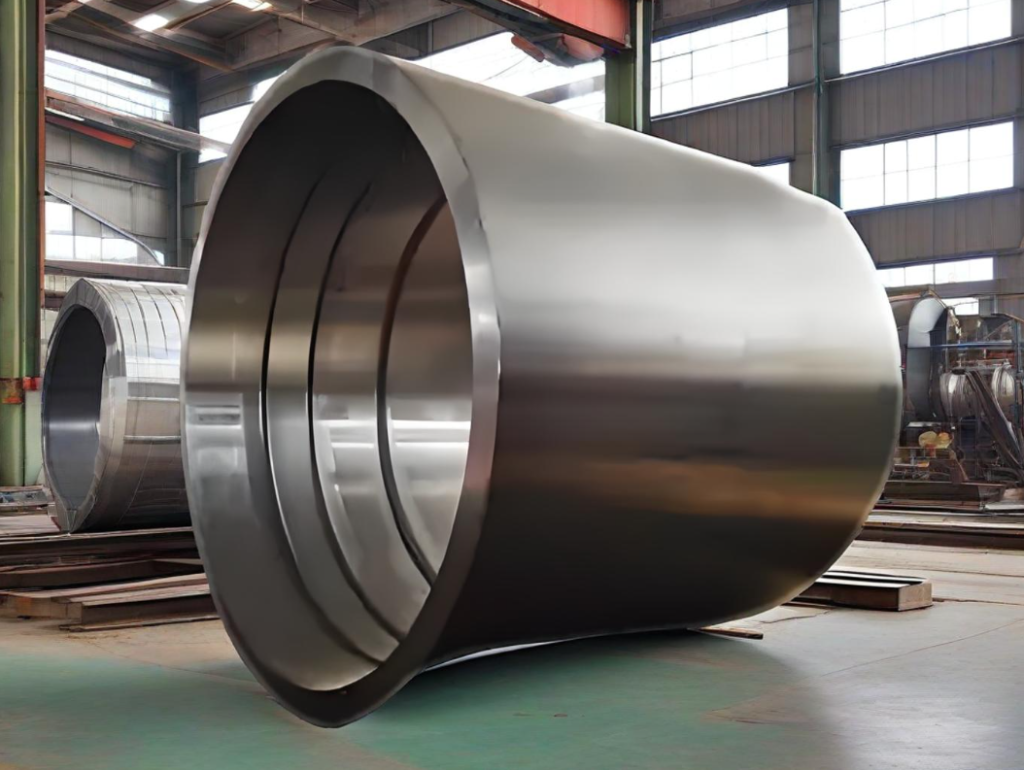

Pressure Vessel Materials: Why Stainless Steel is Popular

Material resolution performs a large position in performance, durability, and regulatory compliance. While carbon metal is frequent in general-purpose applications, stainless metal strain stainless steel pressure vessels offer:

Excellent corrosion resistance

Extended lifespan

Easy cleansing and maintenance

Compatibility with aggressive or high-purity media

These advantages make SS strain pressure vessels best for offshore, food-grade, or pharmaceutical structures the place failure is no longer an option.

Choosing a Reliable Pressure Vessels Manufacturer

Not all stress vessels producers are created equal. When selecting a supplier, prioritize:

ASME certification: This ensures your vessel meets industry-recognized protection and high-quality standards.

Custom fabrication capability: Your technique stipulations may additionally require specialised dimensions, fittings, or materials.

Traceability and QA: From cloth sourcing to closing inspection, pinnacle producers grant full documentation and trying out records.

At Tiptop Forging, we provide full-service strain vessel manufacturing with a focal point on quality, traceability, and worldwide standards.

Compliance with ASME Standards for Pressure Vessels

The ASME Boiler and Pressure Vessel Code (BPVC) units the international benchmark for protection and performance. Compliance with ASME requirements for strain vessels includes:

Structural graph beneath stress and temperature criteria

Welding qualification and inspection

Pressure trying out (hydrostatic or pneumatic)

Stamping and documentation

Working with a licensed producer ensures your tools is legally compliant and insurable throughout worldwide markets.

Key Factors to Consider Before Purchasing a Pressure Vessel

Before deciding on a strain vessel for your industrial application, think about the following:

| Criteria | Importance |

| Pressure and temperature | Ensures vessel integrity under stress |

| Material selection | Avoids corrosion and degradation |

| Size and volume | Matches flow and storage requirements |

| Mounting orientation | Vertical vs. horizontal space considerations |

| Industry standards | Must comply with ASME, API, or ISO |

| Maintenance accessibility | Impacts downtime and lifecycle cost |

These elements without delay have an effect on your operational effectivity and ROI.

Request a Quote for a Custom Pressure Vessels

Looking for a dependable pressure vessels manufacturers?

We provide custom-engineered stainless metal strain vessels and ASME-compliant designs for a broad vary of applications.

Let Tiptop Forging assist you locate the best vessel for your particular process, environment, and overall performance needs.