Introduction: Why Choosing the Right Large Forgings Matters

Large forgings are essential elements in heavy industries such as stress vessels, petrochemical plants, non-stop casting pipe molds, marine engineering, metallurgy, mining, thermal power, hydropower, wind energy, turbines, and generator sets. The preference of a dependable massive forging dealer can at once have an impact on the safety, durability, and operational reliability of your equipment.

This entire buyer’s information walks you via the whole lot you want to be aware of earlier than sourcing— from perception distinctive sorts of massive forgings to evaluating manufacturers—so you can make a well-informed buying decision.

What Are Large Forgings?

Large forgings refer to solid steel components extensively large in dimension and weight than preferred components. These are commonly produced via open die forging or heavy press forging techniques and are made from carbon steel, alloy steel, stainless steel, aluminum, or titanium, relying on the application.

Common Types of Large Forgings Include:

Reactor shells, heads, tube sheets, and interior elements (e.g., help rings and distributor plates)

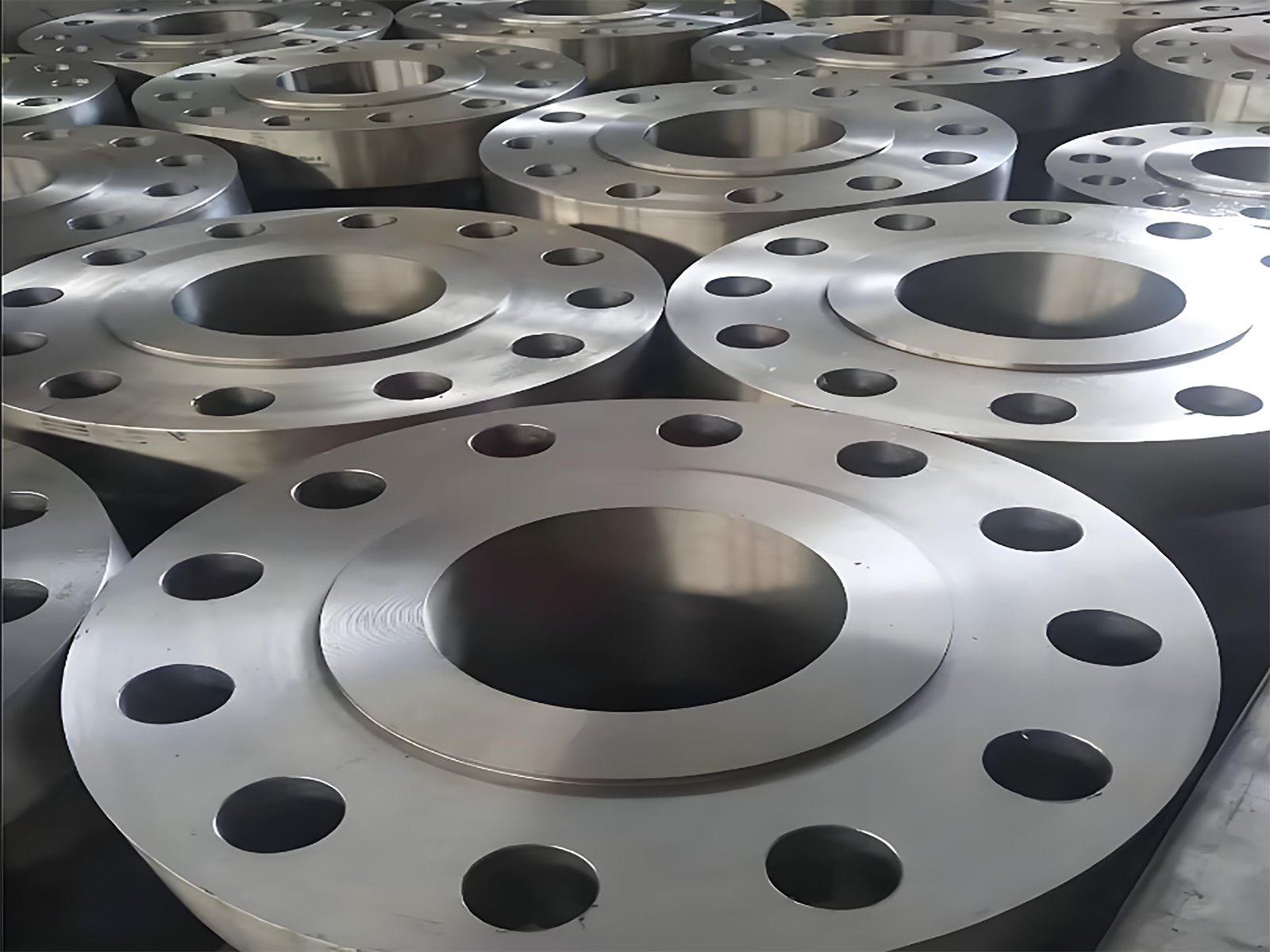

Forged flanges and gear forgings

These elements require most efficient mechanical power and structural integrity, making the desire of forging method integral to reaching favored performance.

Key Factors to Consider Before Sourcing Large Forgings

1. Define Your Application Requirements

Before contacting any China giant forgings manufacturer, you ought to certainly outline your technical and operational needs:

Load-bearing capacity

Dimensional tolerance and floor finish

Environmental stipulations (e.g., corrosion, excessive temperature)

Compliance with requirements such as ASTM, ASME, API, ISO

2. Choose the Right Forging Material

The overall performance of massive forgings relies upon mostly on the cloth selected:

4140 massive forgings: Known for durability and incredible fatigue resistance

Stainless metal forgings: Ideal for corrosive or marine environments

Aluminum forgings: Lightweight answer for aerospace and marine use

Titanium forgings: Perfect for high-performance, low-density applications

Alloy forgings: A balanced preference for strength, weldability, and put on resistance

3. Select the Appropriate Forging Process

For low-volume or outsized parts, open die forgings provide flexibility and cost-efficiency. For high-volume, precision parts, a massive forging hammer or press can obtain tighter tolerances and greater consistency.

Key Specifications When Ordering Large Forgings

Accurate specs make sure a smoother manufacturing manner and most desirable stop performance:

Size range: Clearly outline outer diameter, length, thickness, etc.

Mechanical properties: Required tensile strength, yield strength, affect values

Heat treatment: Normalize, quench & temper, or anneal relying on application

Testing and certification: Include ultrasonic testing, have an effect on testing, and full traceability documentation

A certified China massive forgings dealer will guide you with technical documentation and engineering comments at the ordering stage.

Applications of Large Forgings Across Industries

Large forgings are used in industries the place structural reliability and long-term overall performance are essential:

Aerospace forgings: Landing gear, engine mounts, and structural frames gain from aluminum and titanium forgings.

Power technology forgings: Steam turbines, gasoline compressors, and nuclear elements count number on high-spec metal forgings.

Mining forgings: Drill shafts, crusher components, and tools forgings are frequently made from 4140 steel.

Marine forgings: Propeller shafts and structural helps rely on stainless metal forgings for corrosion resistance.

Why Choose Tiptop Forging for Your Large Forging Needs?

At Tiptop Forging, we specialize in providing custom-made giant forgings for annoying industrial applications. As a depended on China massive forgings manufacturer, we offer:

Tailor-made engineering: From giant forge hammers to outsized rings and shafts

Wide fabric capabilities: Including metal forgings, alloy forgings, stainless steel, and unusual metals

Full method control: From uncooked fabric to remaining machining

Certified production: PSL1–3 and PR1 requirements for oilfield and electricity era applications

Global delivery: We grant giant forgings to North America, Europe, the Middle East, and Southeast Asia

Whether you require marine forgings with excessive strength, aerospace forgings with precision, or mining forgings with intense durability, our group is geared up to supply custom-engineered options backed via rigorous satisfactory control.

Conclusion: Choose the Right Partner for Your Forgings

Sourcing exceptional massive forgings isn’t always simply about discovering the lowest price—it’s about deciding on a dealer who is aware your industry, offers to specific specifications, and helps you for the duration of the process.

With deep trip in the forgings industry, Tiptop Forging is your dependable companion for open die forgings, customized forgings, and more. Contact us these days for a quote or to talk about how we can aid your subsequent project.