AISI 4140

AISI 4140is a versatile chromium-molybdenum (chromoly) alloy steel renowned for its high strength, toughness, and fatigue resistance. It is widely used in applications requiring exceptional mechanical performance under stress, particularly after heat treatment.

Descriptions

1. Chemical Composition

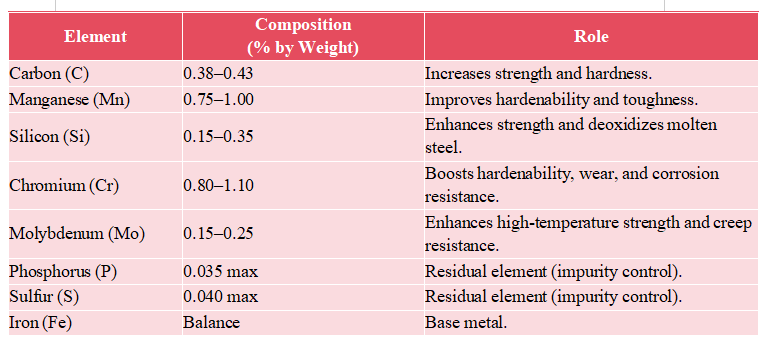

AISI 4140 contains chromium and molybdenum for enhanced hardenability, strength, and wear resistance. Its composition allows for tailored properties through heat treatment.

| Element | Composition (% by Weight) | Role |

| Carbon (C) | 0.38-0.43 | Increases strength and hardness. |

| Manganese (Mn) | 0.75-1.00 | Improves hardenability and toughness. |

| Silicon (Si) | 0.15-0.35 | Enhances strength and deoxidizes molten steel. |

| Chromium (Cr) | 0.80-1.10 | Boosts hardenability, wear, and corrosion resistance. |

| Molybdenum (Mo) | 0.15-0.25 | Enhances high-temperature strength and creep resistance. |

| Phosphorus (P) | 0.035 max | Residual element (impurity control). |

| Sulfur (S) | 0.040 max | Residual element (impurity control). |

| Iron (Fe) | Balance | Base metal. |

2. Mechanical Properties

AISI 4140 forgings achieve exceptional mechanical properties through heat treatment. Values vary based on processing conditions (e.g., normalized, quenched, and tempered).

| Property | Normalized | Quenched &Tempered | Annealed | TestStandard |

| Tensile Strength | 655-795 MPa | 950-1100 MPa | 560-675 MPa | ASTME8 |

| Yield Strength (0.2% offset) | 415-585 MPa | 850-1000 MPa | 345-485 MPa | ASTME8 |

| Elongation (%in 50 mm) | 18-22% | 12-18% | 20-25% | ASTM E8 |

| Reduction of Area | 50-60% | 45-55% | 55-65% | ASTM E8 |

| Hardness (Brinell) | 197-235 HB | 285-341HB | 170-210 HB | ASTME10 |

| Impact Toughness (Charpy V) | 40-60J(room temp) | 25-45J | 50-70J | ASTM E23 |

3. Key Advantages

High Strength & Toughness: Suitable for dynamic and impact loads.

Heat Treatability: Properties tailored via quenching, tempering, or annealing.

Wear Resistance: Ideal for abrasive environments.

Fatigue Life: Performs well under cyclic stress (e.g., rotating machinery).

4. Typical Product Names

Forged Gears

Heavy-Duty Axles

Hydraulic Cylinder Rods

High-Strength Fasteners

Turbine Shafts

Recent products

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Landing gear parts, engine mounts, and structural fittings.

Crankshafts, axle shafts, gears, and suspension components.

Drill collars, valve bodies, and pump shafts.

Hydraulic rods, spindles, heavy-duty bolts, and dies.