AISI 8620

It is designed to achieve a hard, wear-resistant surface while maintaining a tough and ductile core, making it ideal for components subjected to high surface stresses and impact loads. Commonly used in automotive, aerospace, and heavy machinery industries, AISI 8620 forgings offer a balance of machinability, heat treatability, and cost-effectiveness.

Descriptions

1. Chemical Composition

AISI 8620 contains nickel, chromium, and molybdenum to enhance hardenability, core toughness, and wear resistance. Its low carbon content makes it suitable for carburizing or nitriding processes.

| Element | Composition (% by Weight) | Role |

| Carbon (C) | 0.18-0.23 | Provides base strength; optimized for carburizing. |

| Manganese (Mn) | 0.70-0.90 | Improves hardenability and deoxidizes molten steel. |

| Silicon (Si) | 0.15-0.35 | Strengthens ferrite and improves cleanliness. |

| Nickel (Ni) | 0.40-0.70 | Enhances core toughness and impact resistance. |

| Chromium (Cr) | 0.40-0.60 | Improves hardenability and wear resistance. |

| Molybdenum (Mo) | 0.15-0.25 | Increases strength and creep resistance. |

| Phosphorus (P) | 0.035 max | Controlled impurity (minimizes brittleness). |

| Sulfur (S) | 0.040 max | Controlled impurity (improves machinability). |

| Iron (Fe) | Balance | Base metal. |

2. Mechanical Properties

AISI 8620 forgings are typically carburized or heat-treated to enhance surface hardness. Properties vary based on processing methods and case depth.

| Property | As-Forged | Carburized &Hardened | Normalized | Test Standard |

| Tensile Strength | 500-650MPa | 800-1000 MPa (Core) | 600-750MPa | ASTME8 |

| Yield Strength(0.2%offset) | 300-450MPa | 550-750MPa(Core) | 350-500MPa | ASTME8 |

| Elongation (% in 50mm) | 20-25% | 10-15%(Core) | 18-22% | ASTME8 |

| Reduction of Area | 50-60% | 40-50%(Core) | 45-55% | ASTME8 |

| Surface Hardness | 170-210HB | 58-63 HRC (Case) | 200-240 HB | ASTME18 |

| Core Hardness(Brinell) | 200-240HB | 28-35 HRC | N/A | ASTME10 |

| Impact Toughness(Charpy V) | 45-70 J(room temp) | 25-45 J(Core) | 50-80J | ASTME23 |

3. Key Advantages

Superior Case Hardening: Achieves high surface hardness (HRC 58–63) with excellent core ductility.

Good Machinability: Easily machined in the annealed or normalized condition.

Cost-Effective: Balances performance and affordability for mass production.

Fatigue Resistance: Ideal for cyclic loading due to tough core and hard surface.

4. Typical Forging Product

Carburized Gears

Forged Camshafts

Heavy-Duty Bushings

Drilling Tool Connectors

Hydraulic Valve Bodies

Recent products

Nuclear Power Head Plate Forging

Turbine Rotor Forging for Steam Power Generation

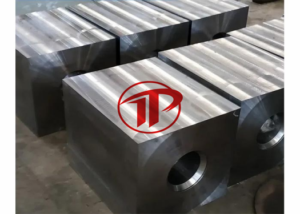

Forged blocks used as valve bodies

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Actuator components, landing gear parts, and engine mounts.

Gears, camshafts, piston pins, and differential cases.

Valve components, drilling tool connectors.

Bushings, shafts, and heavy-duty bearings.

Sprockets, clutch hubs, and drive shafts.