Description

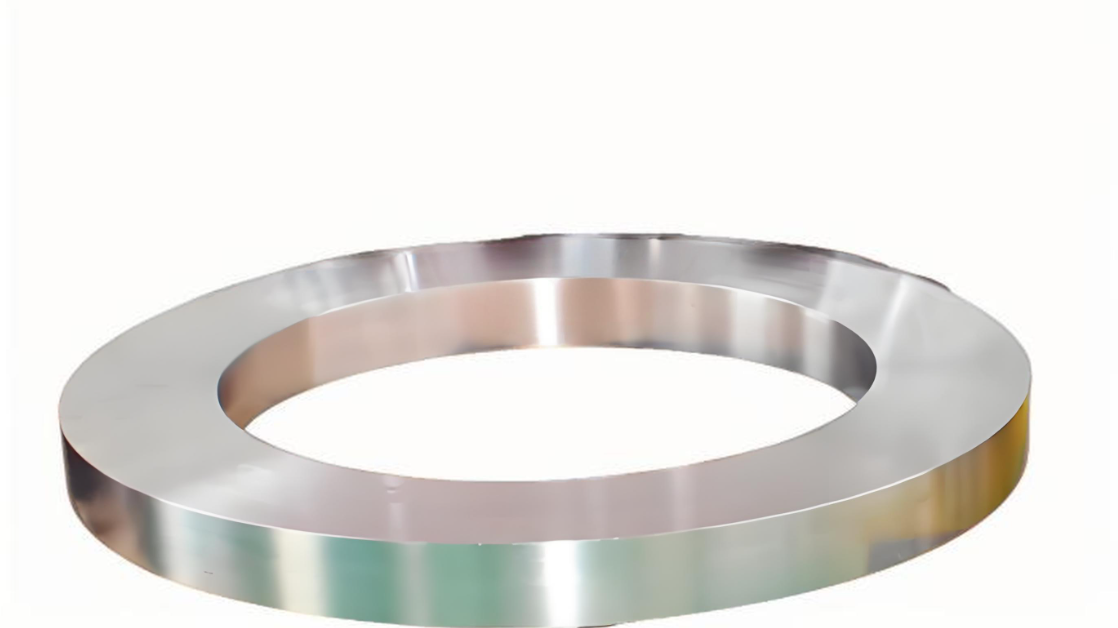

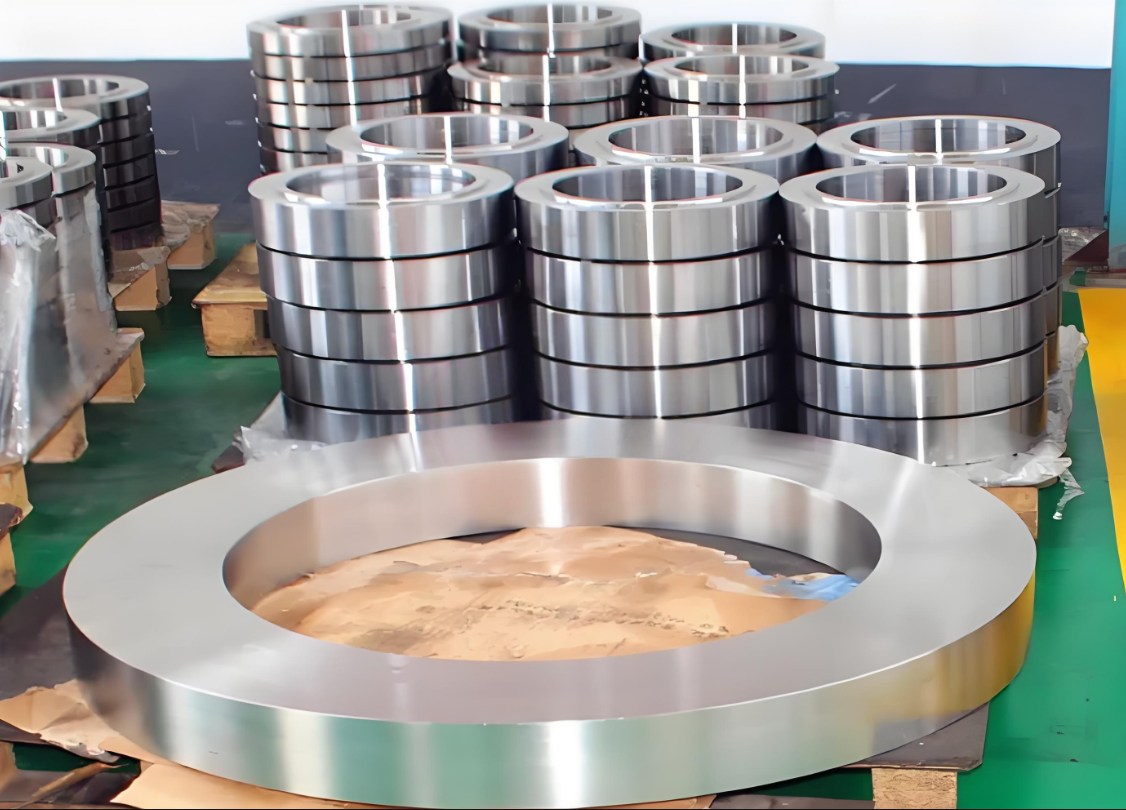

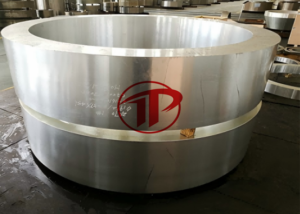

Precision Aluminum Ring Forging Solutions for Demanding Industries

Aluminum ring forging is a manufacturing process that transforms aluminum alloy billets into high-strength, seamless rings through compressive force. Our aluminum forged rings are engineered to meet the toughest specifications, making them ideal for aerospace, automotive, defense, marine, and industrial applications.

Here are some benefits of choosing our aluminum forged rings:

✅Excellent strength-to-weight ratio – for high-performance and weight-critical industries

✅ Seamless Construction – Eliminates weak points andr improved fatigue and stress resistance

✅ Excellent Corrosion Resistance – for marine, aerospace, and outdoor environments

✅ Custom Sizes and Alloys – Tailored to your project requirements

✅ Certified Quality – manufactured to various international standards

Typical Applications of Aluminum Forged Rings

| Industry | Application Examples | Benefits of Forged Aluminum Rings |

| Aerospace | Jet engines, landing gear, satellite frames | Lightweight, high fatigue resistance |

| Automotive | Transmission gears, steering systems | High strength, consistent grain structure |

| Defense | Missile components, radar housing | Durability in extreme conditions |

| Marine | Propulsion systems, structural supports | Corrosion resistance in saltwater environments |

| Industrial | Bearing housings, flanges, pressure vessels | Dimensional accuracy, strength at temperature range |

Available Aluminum Alloys for Forging

We offer forged rings in a wide range of high-performance aluminum alloys, including:

6061 – General-purpose, excellent weldability and corrosion resistance

7075 – High-strength aerospace alloy with excellent fatigue performance

2024 – Excellent machinability and toughness, ideal for aerospace components

7050 – Corrosion-resistant and high-stress-capable aerospace-grade alloy

Your Trusted Partner for Aluminum Ring Forging

📞 Contact us today to request a quote or discuss your project specs!

Reviews

There are no reviews yet.