Description

H2: Why Alloy Steel Forged Bars Are Ideal for Oil & Gas Applications

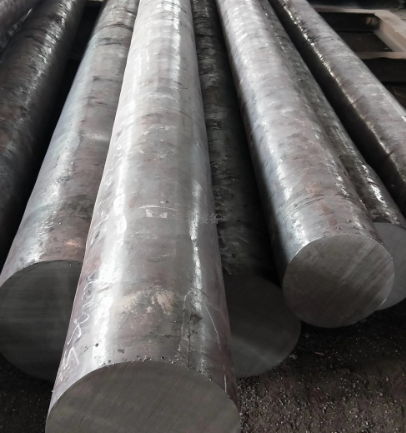

Forged bars made from high-performance alloy steels are a relied on desire in the oil and fuel industry. With highest quality mechanical strength, amazing have an effect on resistance, and remarkable fatigue life, solid bars outperform traditional rolled or forged substances in harsh drilling, extraction, and processing environments.

Key Performance Advantages:

✅ High tensile strength & impact resistance

✅ Excellent resistance to fatigue and stress rupture

✅ Reliable performance under high pressure and temperature

✅ Low risk of internal defects (voids, porosity, inclusions)

H2: Materials & Standards We Offer

We supply alloy steel forged bars that meet or exceed international specifications, including:

Grade Standard Typical Applications

AISI 4140 ASTM A29 / EN 10083 Shafts, wellhead components

AISI 4340 ASTM A322 / EN 24 Drill collars, valves

17CrNiMo6 DIN EN 10084 Gear shafts, flanges

42CrMo4 EN 10250 Couplings, pump parts

F22 / 2CrMo ASTM A182 High-pressure pipeline components

📌 All bars can be delivered in quenched & tempered condition with mechanical property certification.

H2: Dimensions & Supply Capabilities

We manufacture and supply forged bars with the following range:

Diameter: 80mm – 800mm

Length: Up to 8 meters (single piece)

Shape: Round, square, rectangular (custom options available)

Delivery condition: Black forged / rough machined / bright peeled / ground

🔧 Custom dimensions and tolerances available based on your technical drawings or specifications.

H2: Applications in the Oil & Gas Sector

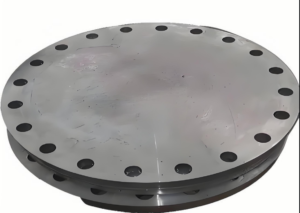

Our alloy steel forged bars are commonly used in:

Drill string components

Valve stems and housings

High-pressure pump shafts

Flanges and couplings

Structural elements in offshore rigs

H2: Quality Assurance & Certifications

We follow strict forging and heat treatment processes, supported by comprehensive testing:

🔍 Ultrasonic Testing (UT) – ASTM A388 Level 2/3

🧪 Mechanical Tests – Hardness, tensile, affect (Charpy V-notch)

📜 Certificates – EN 10204 3.1 / 3.2, NACE MR0175, API, ISO 9001

H2: Why Choose Us as Your Forged Bar Supplier?

Over 20 years of ride serving oil & fuel OEMs and EPC contractors

In-house forging, warmness treatment, machining & checking out

Global delivery with fast lead times and flexible MOQ

Expert technical support for material selection & drawing review

H2: Request a Quote or Technical Consultation

Ready to upgrade your components with high-performance alloy steel forged bars?

Reviews

There are no reviews yet.