Description

Introduction

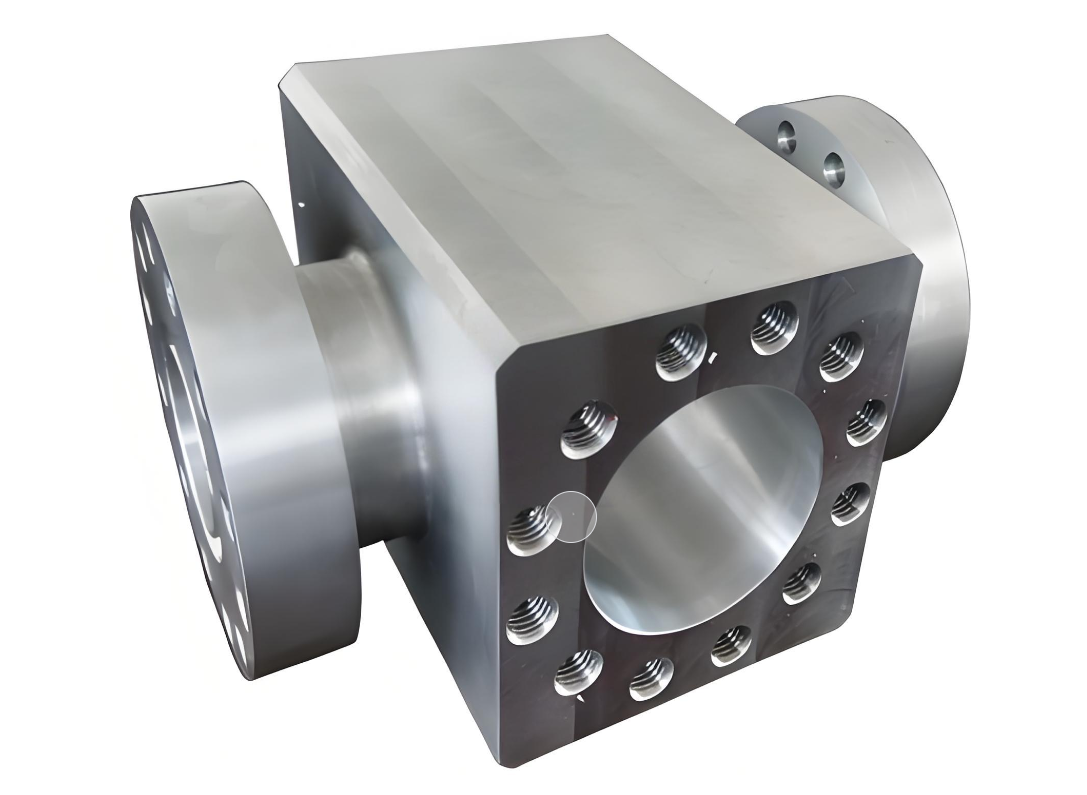

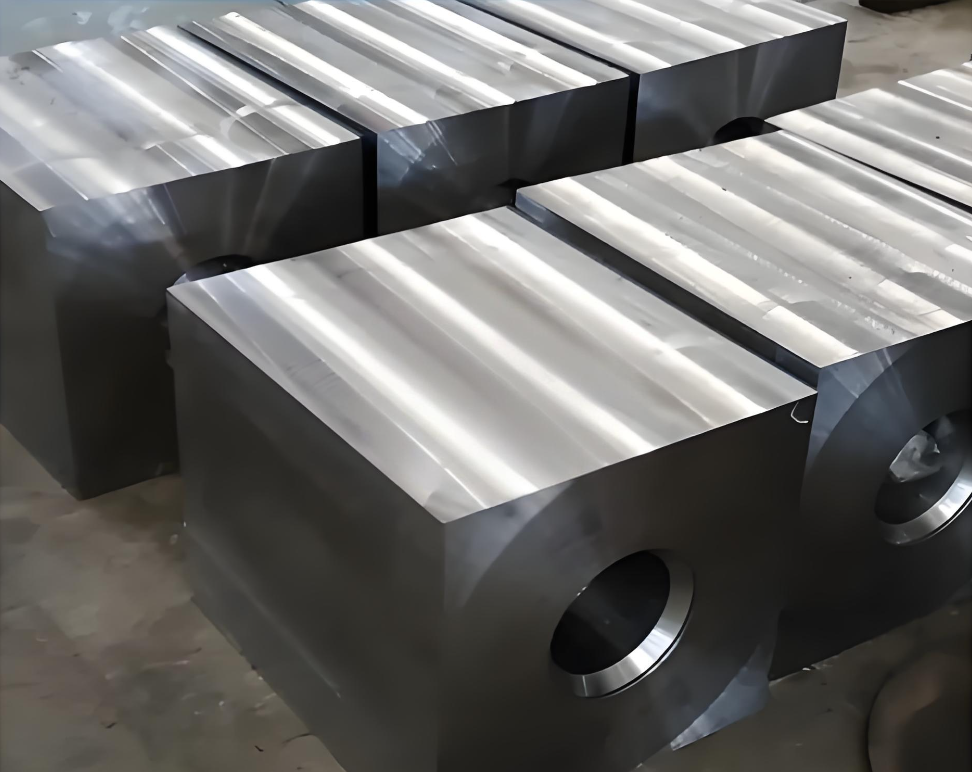

Forged Cylinder Blocks are precision-forged metallic factors designed for heavy-duty equipment. Compared to forged or welded alternatives, they provide greatest strength, durability, and reliability — making them perfect for oil & gas, construction, marine, and energy technology industries.

Why Choose Our Forged Cylinder Blocks?

✅ High Strength & Durability – Refined grain shape improves longevity and fatigue resistance

✅ Consistent Quality – Minimized inside voids and inclusions for longer carrier life

✅ Custom Solutions – Tailored sizes, shapes, and substances accessible for your application

✅ Better Surface Finish – Enables precision machining and rapid assembly

✅ Material Variety – Carbon steel, alloy steel, stainless steel, and nickel alloys

Typical Applications

Oil & Gas: Pump and compressor blocks

Power Generation: Engine and turbine blocks

Marine: Shaft and propulsion components

Heavy Equipment: Hydraulic and engine blocks

Automotive & Transportation: High-performance engine blocks

Material Options

Available in a vary of top class materials, including:

Carbon Steels: A105, A350 LF2

Alloy Steels: 4140, 4340, F22, F91

Stainless Steels: 304, 316, 410, 17-4PH

Nickel Alloys: Inconel 625, Incoloy 825

All blocks conform to global requirements such as ASTM, ASME, EN, ISO, and API.

Why Choose Us?

✅ Advanced forging and precision machining capabilities

✅ Complete traceability (Material certifications, UT inspection, take a look at reports)

✅ Custom engineering to in shape your specifications

✅ Global export trip with tightly closed packaging and well timed delivery

✅ Competitive pricing for premium-quality cast products

Technical Parameters

| Parameter | Specification |

| Material Options | Carbon Steel, Alloy Steel, Stainless Steel, Nickel Alloys |

| Forging Method | Open Die / Closed Die Forging |

| Diameter Range | 100mm–2000mm |

| Length Range | 100mm–6000mm |

| Weight Range | 100kg–30,000kg |

| Heat Treatment | Normalizing, Quenching, Tempering |

| Surface Finish | Rough Forged, Rough Machined, Final Finish |

| Compliance Standards | ASTM, ASME, EN, ISO, API |

| Testing Methods | UT, MPI, Hardness Testing, Material Composition Testing |

| Certifications | EN10204 3.1 / 3.2, NDT Reports available upon request |

Reviews

There are no reviews yet.