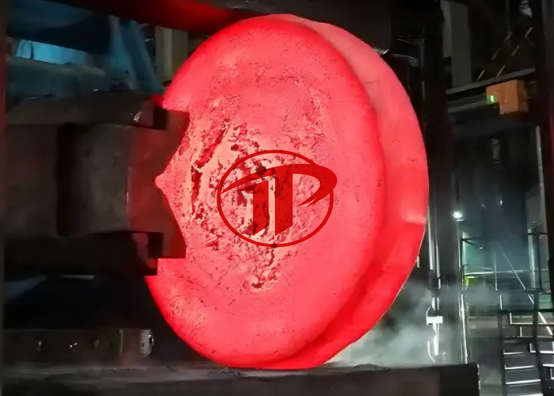

Forging Parts Applicable Industries

Application and Advantages in Forging Industry

In the oil and gas industry, the characteristics of forgings ensure the sealing and safety of forgings in high-pressure environments. In the mining field, forgings significantly improve wear resistance and impact resistance through grain refinement technology to meet the needs of high-intensity ore mining. In the power generation industry, forgings have both high-temperature creep resistance and nuclear-grade material reliability to ensure long-term stable operation of generator sets. In the aerospace field, forgings use precision forging technology to achieve a combination of lightweight and ultra-high strength to meet the extreme mechanical environment requirements in supersonic flight. The common advantages of the entire industry are reflected in the forging process that eliminates internal defects of the material, improves the consistency of mechanical properties, and adapts to the complex working conditions you want through customized production.

Four Major Industries of our Forgings

Our company is dedicated to providing high-quality forgings to the oil and gas, mining, power generation and aerospace industries. With our expertise in forging technology and quality control, we are confident that our products can meet the demanding requirements of these industries and contribute to their success

If you have any questions or would like a free quote please contact us

Applied products: high-pressure valves, pipeline flanges, wellhead devices, and drilling equipment connectors

Advantages: The forging process can improve the density of components and ensure long-term stable operation in high-pressure and corrosive environments; the material has excellent resistance to hydrogen sulfide corrosion and reduces the risk of oil and gas transmission leakage

Case: A high-pressure valve in a deep-sea oil and gas field uses precision forging technology, with no internal pore defects, and has been running continuously for 5 years under a high-pressure environment of 35MPa without leakage accidents.

Application products: Crusher main shaft, mining gear, hydraulic support shaft, excavator bucket teeth

Advantages: Forging parts significantly improve wear resistance and impact resistance through grain refinement, adapting to high load and complex working conditions in ore mining; the overall structural strength is high, reducing the risk of equipment fracture due to stress concentration

Case: The main shaft of a crusher in an open-pit mine adopts 42CrMo alloy forging technology, and its service life reaches 18 months under the condition of crushing basalt, which is 3 times longer than the original casting.

Applied products:

Nuclear power: nuclear island main pump housing, reactor pressure vessel flange, steam generator support ring

Thermal power: steam turbine rotor, blades and couplings

Gas power generation: gas turbine turbine disc, combustion chamber high temperature parts

Advantages: Nuclear power forgings meet the strict non-destructive testing requirements of nuclear grade materials; thermal power and gas turbine forgings have excellent high temperature creep resistance, ensuring long-term stable operation of the unit above 550℃

Nuclear power case: The reactor pressure vessel flange of the AP1000 nuclear power unit is integrally forged with 316LN stainless steel, which passes 100% ultrasonic flaw detection and meets the 60-year design life requirement.

Thermal power case: The steam turbine rotor forging of the 660MW ultra-supercritical unit is forged with vacuum degassed steel ingots, and the creep rupture strength is maintained above 350MPa under 600℃ working conditions.

Applied products: aircraft engine turbine blades, landing gear load-bearing structural parts, space launch vehicle engine casings

Advantages: The high-temperature alloy precision forging process is used to achieve a combination of lightweight and high-strength components; forged parts have a long fatigue life and can withstand high-frequency vibrations and extreme temperature changes during supersonic flight

Case: A commercial aircraft engine turbine disc is isothermally forged with IN718 high-temperature alloy. The fatigue life exceeds 50,000 hours at 650℃/1000rpm, which is 70% higher than the traditional process.

Product Customization Services for the Forging Industry

- Our advanced forging technology can create unique products, parts and shapes for a variety of industries and applications.

- With more than two decades of experience, we have the knowledge and expertise to manufacture custom forgings to the exact specifications of your project.

- TIPTOP also offers a variety of additional services to enhance the quality and value of your forged blocks

Covering the complete technology chain of material selection, process simulation and finished product inspection, we provide a quality assurance system based on international standards such as ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 to ensure the reliability of products from development to delivery

Equipped with an experienced team of engineers to support the optimization of forging solutions under complex working conditions (such as high temperature/pressure/corrosion environment)

Meet the stringent requirements of the oil/gas, nuclear and other industries

For wind power/nuclear power and other special scenarios, the development of salt spray corrosion resistance, high temperature resistance and other special alloy forging solutions

Each Inspection Process of Forging Materials

Raw Material Quality Control

In-Process Quality Monitoring

Finished Product Quality Inspection

Raw Material Quality Control

We strictly approve raw material suppliers and

conduct chemical composition analysis and

visual inspections on incoming raw materials.

This ensures the quality of raw materials,

guaranteeing product quality from the source.

In-Process Quality Monitoring

During production, we strictly monitor the

quality of each process, including dimensional

checks and surface quality inspections.

We promptly correct any issues found to ensure

stable and controllable production processes.

Finished Product Quality Inspection

Before product release,we conduct comprehensive quality inspections, including

hardness testing, flaw detection, and

mechanical properties testing.

This ensures each product meets standards in performance and quality, giving customers

confidence in our products.

Instruments used in the Process of Forging Materials

From raw material intake to finished product release, we strictly control quality at every stage to ensure stable product performance.

Thread detector

- Accurately measure thread parameters

- Automatically determines thread integrity

spectrograph

- Accurate testing of raw material composition

- Dynamic monitoring of production process

- Finished product quality conformance verification

Carbon sulfur analyzer

- Precise control of material composition

- Optimize the smelting and forging process

- Quality traceability and standardization certification

Universal testing machine

- multi-dimensional mechanical properties test

- High temperature and high pressure environment simulation

- Precision control and data acquisition

Nondestructive testing

- Defect detection and location

- Material performance evaluation

- Geometric parameter measurement

- Dynamic monitoring and prediction

Metallographic microscope

- Analysis of microstructure

- Defect and contamination detection

- Whole process data support

Reputation certification

Our ISO certificate

As an ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 certified forging manufacturer, we embody global standards for quality precision, sustainable operations and workplace safety.

International Customers

TIPTOP will always be your reliable partner in the oil and gas industry

For overseas,Our products are mainly exported to North America, Central Asia, and the Middle East, including the United States, Canada, Russia, Kazakhstan, the United Arab Emirates, Kuwait, Saudi Arabia, Oman, Malaysia, India Indonesia, and other countries.

The Process in the Production of Forging Materials

Flexible machining of complex shapes: Free forging eliminates the need for complex molds to produce large or shaped parts (such as ship spindles, aircraft frames) to meet your customized needs

Strong Technical Support

From raw materials, forging process,heat treatment, machining, etc., we have experts to provide strong technical support. In addition to industry standard products,we provide customization and R&D services

Quality Assurance

Each product undergoes strict quality testing, we accept any third party inspection and each product can be supplied with prolonged or separate test coupon for customer to recheck

Complete integrated supply service

.Long-term cooperation with high- quality raw material mills & stockists to ensures efficient material supply. ·Close cooperation with API machine shops, can support finished products supply.

Core advantages of ODM metal forging

- Independent design mold opening capability :

support the whole process design from drawings to finished products, covering complex geometric shapes such as special-shaped structure and porous position, reducing secondary processing costs

- Vertical integration industry chain :

From raw material processing (such as steel plate pretreatment) to system integration and whole machine testing, the whole chain independent manufacturing reduces the cost of intermediate links and ensures quality control

- Whole process quality inspection:

From raw material testing (such as metal composition analysis) to third party certification of finished products (such as ultrasonic inspection, hardness testing), ensure that compressive strength, fatigue life and other indicators meet the standards

42CrMo4 Large Alloy Steel Forged Block For Hot Forging Mould Chemical composition interacts with key elements

element

Content range (%)

Functional characteristics

| C |

| 0.38-0.45 |

Provides base hardness and strength, balancing toughness and wear resistance

| Cr |

| 0.9-1.2 |

Improved hardenability, corrosion resistance and high temperature oxidation resistance

| Mo |

| 0.15-0.30 |

Inhibit temper brittleness, enhance high temperature strength and thermal fatigue resistance

| Mn |

| 0.6-0.9 |

Improve hardenability and machinability

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com