Description

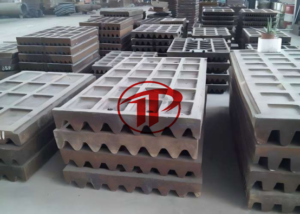

Dual-flange Spacer Spool Forging is a fundamental aspect used to join sections of a wellhead or pipeline machine the place specific spacing, alignment, and sealing are essential. Designed for high-pressure oil and gasoline operations, these forgings make certain safe, leak-proof connections whilst supplying extraordinary power and durability.

Our Dual-flange Spacer Spool Forging options are manufactured to meet or exceed API 6A specs and can be totally custom-made to your specific requirements.

Product Features and Benefits

- High-Strength Forging Process

We use superior open-die and closed-die forging strategies to create seamless, grain-aligned forgings for top-quality mechanical properties. This ensures most strain containment and resistance to fatigue.

- Precision Machined Flanges

Each flange shaft is precisely machined to make certain ideal alignment with mating components, decreasing set up time and danger of leakage. Our shaft flange interfaces warranty dependable sealing even underneath severe pressure.

- Custom Spacer Lengths

We manufacture spacer spools in customized lengths to exactly healthy your wellhead or manifold layout, making sure top-quality performance.

- Corrosion-Resistant Materials

Available in carbon steel, alloy steel, and stainless metal grades appropriate for bitter provider or offshore environments.

- API 6A and ISO Certified

Full traceability and certification make certain compliance with worldwide oil and gasoline enterprise standards.

Applications in Oil & Gas

Wellhead assemblies

Manifold connections

Blowout preventer (BOP) stacks

Pipeline tie-ins

These Dual-flange Spacer Spool Forgings are used extensively in high-pressure drilling and production systems where safe, reliable connections are essential.

Related Flanged Shaft and Coupling Solutions

To ensure full system integration, we also produce a wide range of flanged shaft and shaft flange components designed for demanding applications:

Shaft with flange: Precision machined shafts for power transmission and rotating equipment.

Drive shaft flange and drive shaft flange yoke: Designed for heavy-duty torque transfer in pumps and compressors.

Drive shaft yokes and flanges: Perfect for custom coupling assemblies.

Flange drive shaft solutions for oilfield and industrial machinery.

Shaft collar with flange and flanged shaft collar: Secure axial positioning on rotating shafts.

Flange mount shaft collar and shaft collar with mounting flange: Ideal for mounting and positioning applications.

Flange shaft coupling: High-strength forged couplings for joining rotating shafts.

Flanged shaft collar with mounting holes: Easy installation and secure mounting in precision equipment.

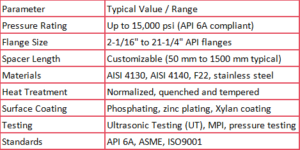

Technical Specifications (Example)

Why Choose Our Dual-flange Spacer Spool Forgings?

In-house forging, machining, and heat treatment for complete quality control

API 6A and ISO-certified production

Custom designs to suit your project needs

Corrosion-resistant and high-pressure capable

Global shipping and full documentation

Contact Us

Need reliable Dual-flange Spacer Spool Forging solutions for your oil & gas project? Contact our team for expert engineering support, competitive pricing, and on-time delivery.

We are ready to help you select or design the shaft flange, flanged shaft collar, drive shaft flange, or spacer spool you need to keep your operations running safely and efficiently.

Reviews

There are no reviews yet.