Description

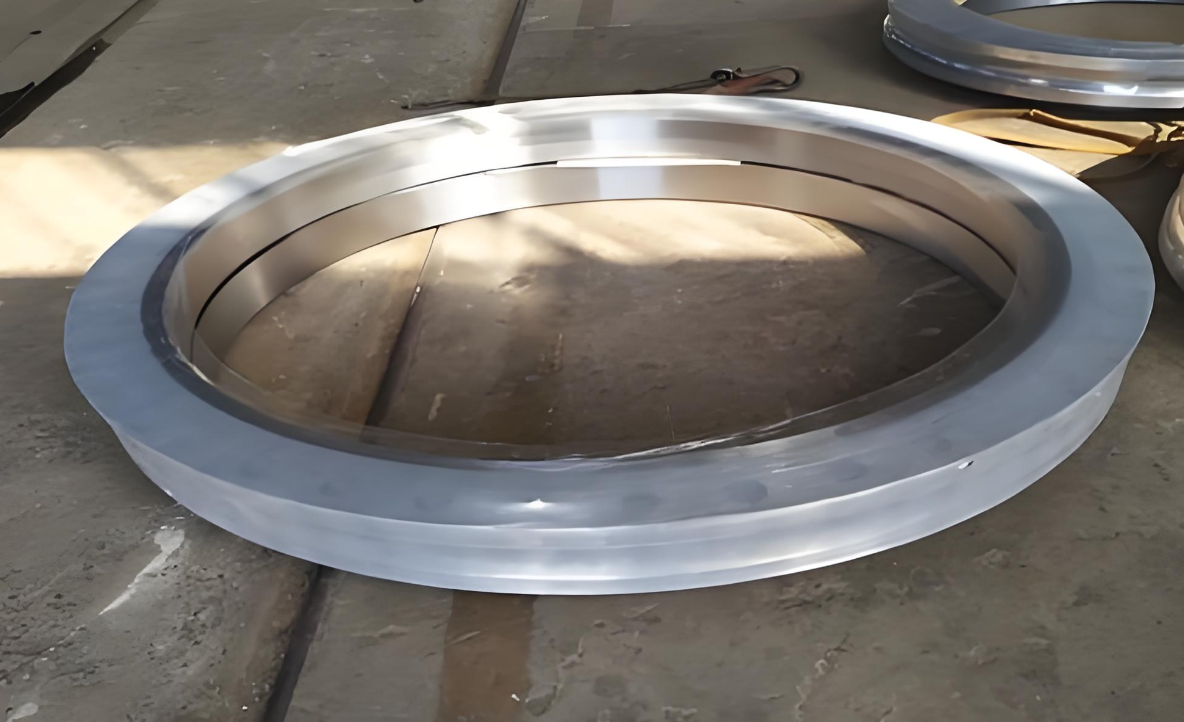

Product Description

The vessel transition part forging is a integral pressure-bearing aspect used in stress vessels, reactors, warmth exchangers, and different high-temperature, high-pressure systems. It serves as a connecting factor between distinctive geometric structures—such as cylindrical shells, domed heads, cones, reducers, or specifically formed interfaces—allowing for clean transitions whilst retaining mechanical energy and sealing performance.

Engineered to face up to inner pressures up to 30 MPa and temperatures ranging from 300°C to 600°C, this forging should additionally suffer cyclic thermal stress and structural masses at some stage in its provider life.

Key Features

Seamless integration between distinct vessel sections

Designed for high-pressure, high-temperature, and fatigue-critical environments

Manufactured from low-alloy, heat-resistant steels compliant with international codes

Precision-forged and heat-treated for more suitable mechanical houses and dimensional accuracy

Technical Specifications

| Parameter | Specification |

| Product Name | Vessel Transition Section Forging |

| Application | Pressure Vessels, Reactors, Nuclear Systems, Chemical Plants |

| Material Options | SA-387 Gr.11 / Gr.22 (ASME) or 16MnDR (GB), others on request |

| Forging Method | Open Die Forging / Customized Die Forging |

| Transition Height | 0.5 – 3 meters |

| Wall Thickness | 20 – 150 mm |

| Taper Angle Tolerance | ±0.5° |

| Outer Diameter Range | Up to 5000 mm (customizable) |

| Heat Treatment | Normalizing + Tempering or Quenching + Tempering |

| Operating Pressure | ≤ 30 MPa |

| Operating Temperature | 300°C – 600°C |

| Delivery Condition | Forged + Heat Treated + Rough/Fine Machined + NDT Tested |

| Inspection Standards | UT/RT/MT as per ASME, EN, or GB standards |

Applications

High-pressure chemical reactors

Petrochemical and gas processing vessels

Nuclear power plant containment and pressure sections

Hydrogenation and desulfurization equipment

Cryogenic and LPG vessel systems (with material adaptation)

Available Material Grades

SA-387 Gr.11 / Gr.22 — Chrome-moly alloy steel for elevated temperature service

16MnDR — Low-temperature pressure vessel steel (Chinese standard)

Other grades available to meet project or regional standards

Quality Assurance

Full traceability of materials and processes

Third-party inspection supported (SGS, BV, TUV, LR, etc.)

Compliant with ASME VIII, PED, GB150, or customer-specified codes

Available with complete documentation: MTC, heat treatment report, NDT records

Reviews

There are no reviews yet.