Steam Turbine Components Manufacturers

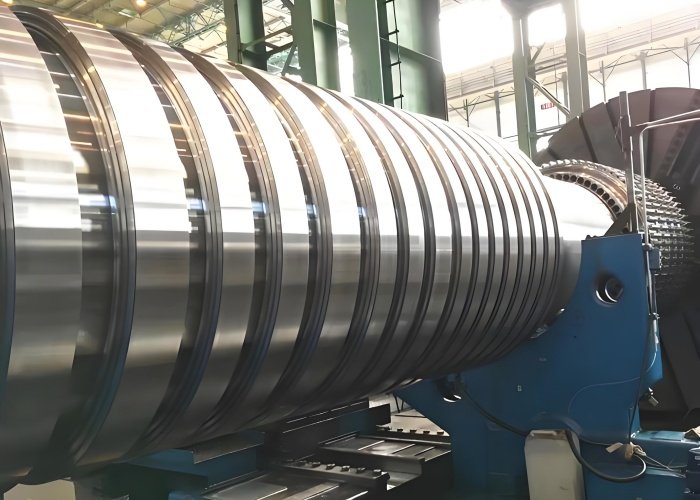

tiptop Steam Turbine Rotors

- Manufactured using high-grade alloy steel and precision forging processes, these rotors ensure strength and durability.

- Steam turbine rotors achieve higher energy efficiency and lower energy consumption during operation.

- This applies to a variety of energy sectors, including thermal, nuclear, and wind power.

- We can design and process rotors to meet customer needs, supporting a wide range of specifications, dimensions, and performance requirements.

Comprehensive Range of Steam Turbine Components

Turbine Rotors

Steam Turbine Rotors (HP-IP, LP) - (Core of the core).

A turbine is a machine with a rotating moving part called a steam turbine rotor, which is a shaft with attached blades. The moving steam acts on the blades so that they run and transmit rotational energy to the steam turbine rotor

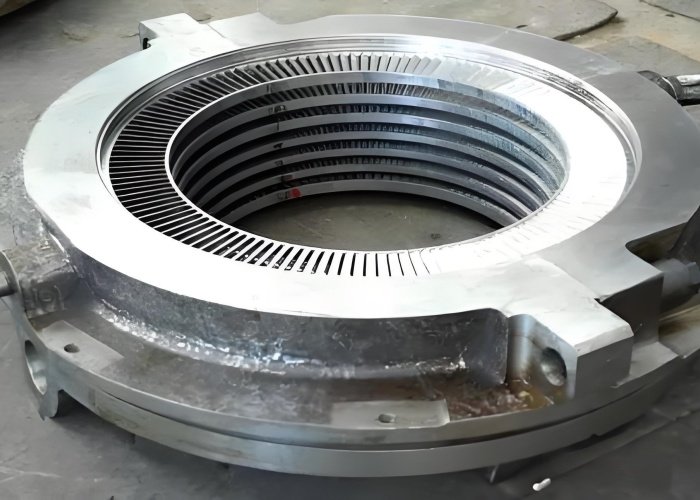

Turbine Casings

Steam Turbine Casings (HP Inner, IP, LP Inner/Outer) - (Large-sized, complex, heat-resistant).

A turbine casing is a pressure vessel that encloses and supports the turbine rotor and other stationary components, housing the high-pressure steam or gas to drive the turbine. These casings are crucial for preventing steam or gas leaks and are designed for high-pressure and temperature conditions,

Turbine Blades

Steam Turbine Blades (Last-stage long blades, especially for nuclear and ultra-supercritical coal power, may require die forging - a 4000-ton press may be used for larger blades)

Turbine blades are airfoil-shaped components in a turbine that convert fluid energy (like steam, gas, or wind) into rotational energy to generate electricity or provide propulsion.

Valves

Valve Bodies / Valves (Main Stop Valve, Control Valve, Reheat Valve, etc.) - (High-temperature, high-pressure).

Steam turbine valves control steam flow and pressure to start, stop, and regulate the turbine’s operation, and are crucial for safety. Key types include stop valves (like Trip and Throttle Valves) that shut down the turbine in emergencies to prevent overspeed.

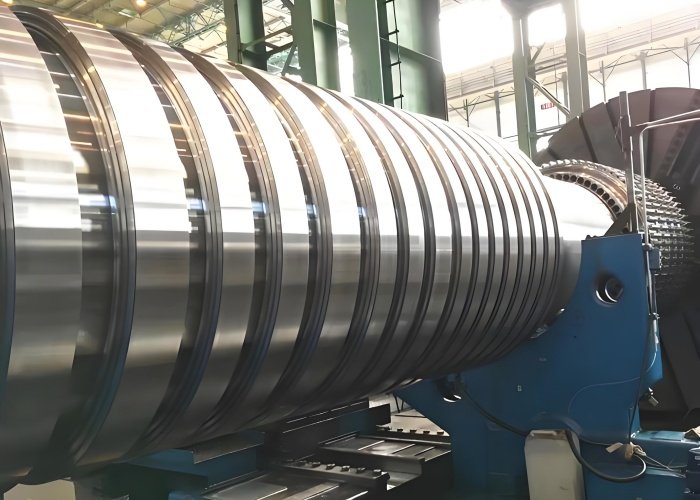

Coupling

Turbine Shaft Coupling (Large-sized, high-precision forging).

The working principle of steam turbine couplings is mainly based on the meshing of internal and external teeth to transmit torque and rotational motion. When the driving shaft rotates, torque is transmitted to the driven shaft through tooth contact and friction, thereby achieving synchronous rotation and power transmission of the two shafts.

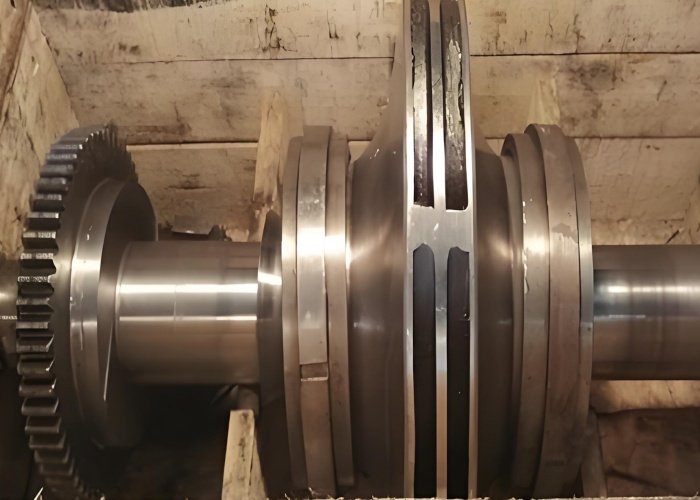

Diaphragm Carriers / Holder Rings

Diaphragm Carrier Rings / Holder Rings (Large ring/cylindrical forgings).

Advanced forging and heat treatment processes ensure uniform metallographic structure and excellent fatigue resistance.

Maintains stability during long-term operation, resisting deformation or cracking.

Suitable for a variety of wind turbine and steam turbine rotor blade configurations.

Suitable for use in extreme temperature and steam environments.

Reduces maintenance frequency and lowers total lifecycle costs.

Other application categories of steam turbine components

As a Chinese forging manufacturer, we at Tiptop not only provide precision forged steam turbine components and steam turbine parts to meet different categories of steam turbine systems, we also provide the following industry components to meet your various needs

The Aerospace Industry Is Renowned For Its Pursuit Of Cutting-Edge Technology And Uncompromising Safety Standards. In This Demanding Environment, Forgings Stand Out As Key Elements That Contribute To The Reliability And Performance Of Aircraft.

Forgings Play A Crucial Role In The Mining Industry, Providing Essential Components That Ensure Efficiency, Safety, And Durability In Various Mining Operations.

Oil And Gas Industry Is A Cornerstone Of The Global Energy Supply, Characterized By High Demands For Efficiency, Safety, And Resilience.

With The Development Of The Energy And Electronics Industries, The Demand For Forgings Continues To Increase. Especially In The Field Of Renewable Energy, Such As Wind Power Generation And Nuclear Power Generation, The Application Of Forgings Will Be Further Expanded.

From the enormous torque transmitted by propeller shafts to the constant hydrodynamic forces experienced by rudder systems, every component must meet the highest standards of strength, reliability, and precision. This is where marine forgings come in – providing high-performance forged products designed for durability and to extend the life of your vessel.

Pressure Vessels Are Vital Factors In A Large Vary Of Industries, From Chemical Processing To Electricity Production. Choosing The Proper Vessel Now Not Solely Ensures Operational Effectivity However Additionally Immediately Affects Safety, Compliance, And Long-Term Cost-Effectiveness.

OUR CUSTOMERS

Our ISO certificate

As an ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 certified forging manufacturer, we embody global standards for quality precision, sustainable operations and workplace safety.