Marine Equipment Heavy Steel Forgings

Premium Materials for Marine Forgings

- High-Strength Alloy Steel: Our marine forgings use alloy steels with excellent toughness, fatigue resistance, and crack prevention, ensuring durability under constant mechanical stress.

- Corrosion-Resistant Properties: Materials are carefully selected to resist seawater corrosion, making marine shaft forging and other critical parts safe for long-term service in offshore and onshore applications.

- Customized Material Grades: We provide tailored steel grades to match specific vessel requirements, from marine equipment solutions for propulsion shafts to heavy forgings for submarine pressure hulls.

Marine Equipment Heavy Steel Forgings Product Range

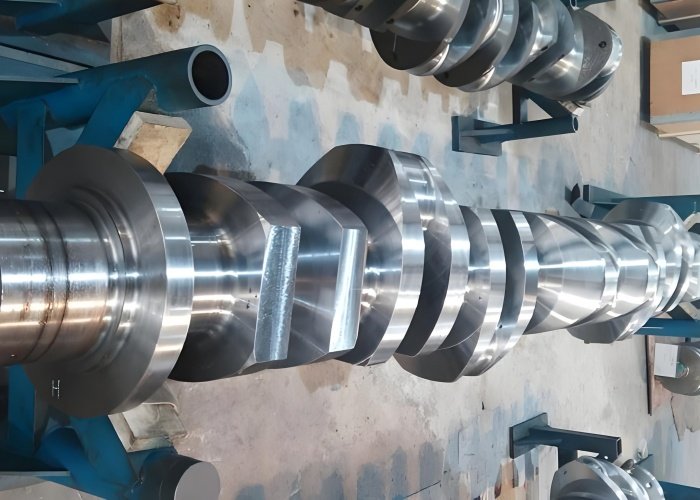

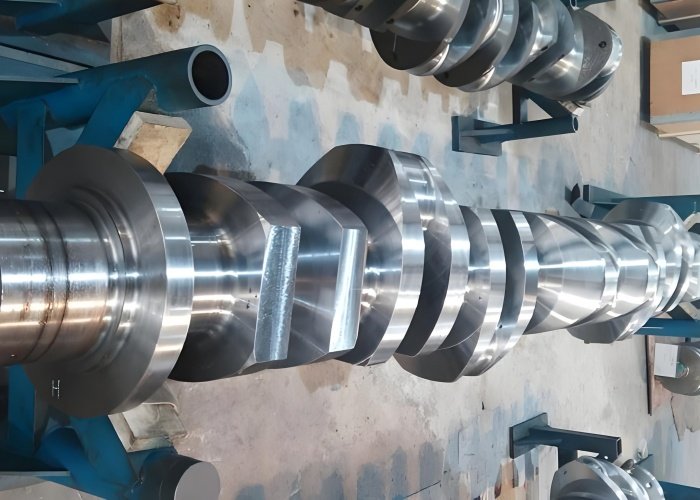

Forged Crankshafts for Marine Slow-Speed Diesel Engines

Our forged crankshafts are manufactured for marine equipment requiring continuous power output. They feature excellent fatigue resistance, uniform grain structure, and long-term durability for slow-speed diesel engines used in large vessels.

Forged Connecting Rods for Marine Slow-Speed Engines

Tiptop marine forgings include connecting rods designed for reliable operation under high pressure. Each rod undergoes ultrasonic testing and precise machining to ensure compatibility and safe engine performance.

Forged Stern Shafts / Forged Intermediate Shafts

We provide marine shaft forging solutions for stern and intermediate shafts, ensuring perfect alignment and torque transmission. These components are critical in propulsion systems, where strength and balance are essential.

Forged Rudder Stocks / Forged Rudder Pins

Our marine forging capability includes rudder stocks and pins forged from high-strength steel. These parts provide stability and safety for vessel navigation, offering excellent resistance against bending and impact loads.

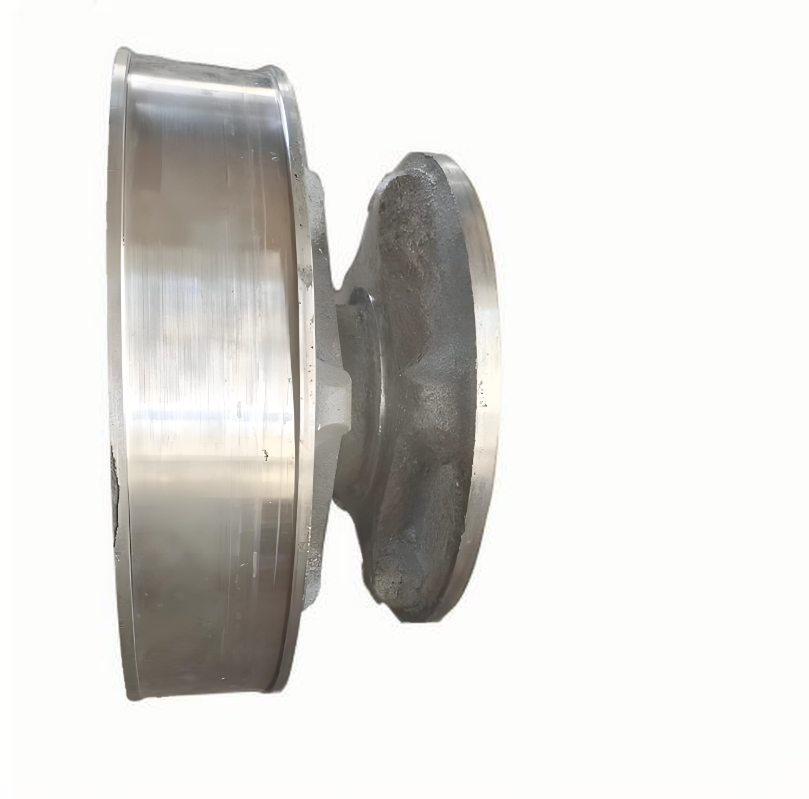

Forged Anchor Chain Wheels (Gypsies) / Critical Forged Components

Forged anchor chain wheels (gypsies) are vital parts of ship mooring equipment, ensuring smooth handling and secure engagement of anchor chains. As critical forged components for mooring equipment, they are designed to withstand heavy loads, harsh marine environments, and continuous operation, providing reliable performance and safety for vessels of all sizes

Heavy Steel Plates / Ring Section Forgings for Submarine Pressure Hulls

We manufacture marine equipment heavy steel forgings in the form of plates and ring sections for submarine pressure hulls. These critical components are forged to meet strict naval standards, offering excellent toughness, impact resistance, and safety under extreme underwater pressure.

Forged Propeller Shafts (Tailshafts) / Forged Propeller Hubs

We provide marine shaft forging solutions for stern and intermediate shafts, ensuring perfect alignment and torque transmission. These components are critical in propulsion systems, where strength and balance are essential.

Propulsion systems demand components with exceptional strength and fatigue resistance. Our marine shaft forging ensures precision, high load-bearing capacity, and long service life under harsh conditions. Each marine forging undergoes heat treatment and non-destructive testing to guarantee performance.

From marine equipment for sale to customized projects, tiptop delivers forgings that fit exact operational requirements. We work closely with clients to provide shaft forgings, crankshafts, and rudder systems that ensure smooth vessel operation

Forging enhances grain flow, producing stronger and more reliable parts compared to casting. Our marine equipment heavy steel forgings provide maximum safety in critical applications such as rudder stocks, propeller shafts, and submarine pressure hulls.

With tiptop marine equipment solutions, customers benefit from components designed to withstand seawater corrosion, high torque, and continuous stress. Our products ensure vessel safety and efficient operation across commercial and naval fleets.

Each marine forging is produced using controlled forging processes that refine grain flow, enhancing strength compared to casting or welding.

Our quality system includes ultrasonic testing, magnetic particle inspection, and dimensional checks to guarantee flaw-free marine equipment.

All marine equipment for sale meets international standards, ensuring compatibility, safety, and performance in global marine operations.

Advanced heat treatment improves mechanical properties, while precision machining ensures perfect fit and reliability in assembly.

Other application categories of Marine Forgings

As a Chinese forging manufacturer, we at Tiptop not only High-Performance Marine Equipment Forgings for Global Applications, we also provide the following industry components to meet your various needs

The Aerospace Industry Is Renowned For Its Pursuit Of Cutting-Edge Technology And Uncompromising Safety Standards. In This Demanding Environment, Forgings Stand Out As Key Elements That Contribute To The Reliability And Performance Of Aircraft.

Forgings Play A Crucial Role In The Mining Industry, Providing Essential Components That Ensure Efficiency, Safety, And Durability In Various Mining Operations.

Oil And Gas Industry Is A Cornerstone Of The Global Energy Supply, Characterized By High Demands For Efficiency, Safety, And Resilience.

With The Development Of The Energy And Electronics Industries, The Demand For Forgings Continues To Increase. Especially In The Field Of Renewable Energy, Such As Wind Power Generation And Nuclear Power Generation, The Application Of Forgings Will Be Further Expanded.

Tiptop Deliver Precision-Forged Steam Turbine Components And Steam Turbine Parts That Match Different Classification Of Steam Turbine Systems. With Deep Knowledge Of The Steam Turbine Working Principle, We Ensure Every Component Improves Reliability And Efficiency.

Pressure Vessels Are Vital Factors In A Large Vary Of Industries, From Chemical Processing To Electricity Production. Choosing The Proper Vessel Now Not Solely Ensures Operational Effectivity However Additionally Immediately Affects Safety, Compliance, And Long-Term Cost-Effectiveness.

OUR CUSTOMERS

Our ISO certificate

As an ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 certified forging manufacturer, we embody global standards for quality precision, sustainable operations and workplace safety.