C10200 Oxygen-Free Copper

C10200 Copper Chemical Composition

Typical chemical composition of C10200 (ASTM B152 / UNS C10200):

Element | Content (%) |

Copper (Cu) | ≥ 99.95 |

Oxygen (O) | ≤ 0.001 |

Other Elements | ≤ 0.05 |

C10200 Copper Mechanical Properties

C10100 shows stable mechanical properties under annealed and hard temper conditions:

Temper | Tensile Strength Rm (MPa) | Yield Strength Minimum Rp0.2 (MPa) | Elongation Minimum A50mm (%) | Hardness HV | Bending 90° gw (rel. Bending Radius R/T) | bw Strip Thickness ≤ 0.50mm |

R220 | 220–260 | ≤ 140 * | 33 | 40–65 | 0 | 0 |

R240 | 240–300 | 180 | 8 | 65–95 | 0 | 0 |

R290 | 290–360 | 250 | 4 | 90–110 | 0 | 0 |

R360 | ≥ 360 | 320 | 2 | ≥ 110 | 0 | 0.5 |

C10200 Copper Manufacturing & Heat Treatment Process

C10200 oxygen-free copper is commonly manufactured by casting, hot rolling, extrusion, and forging.

- Forging temperature range: 760–870 °C

- Annealing temperature range: 400–600 °C

- Heat treatment: Usually supplied in annealed temper to maximize conductivity and formability

- Workability: Excellent for cold forming, brazing, and soldering

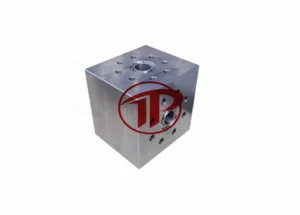

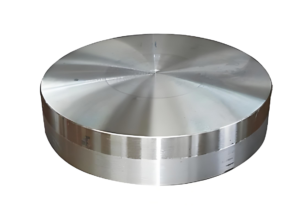

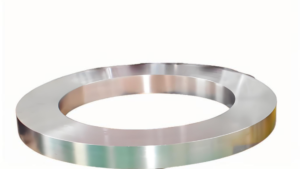

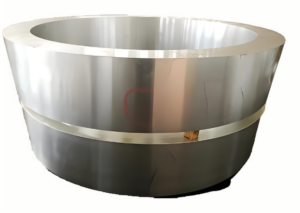

- Weldability: Good for gas shielded arc welding, limited suitability for resistance weldingAt Tiptop Forging, we specialize in producing C10200 forged bars, rings, and custom copper components, ensuring tight dimensional tolerances and reliable performance.

Recent products

API 6A Studded Cross

Aluminum Forged Rings for Aerospace & More

API 6A AISI 4130 Forged Steel Round Hollow Bar

Aluminum Forgings for Aerospace Applications

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

C10200 Copper Applications

Due to its superior purity and electrical conductivity, C10200 is widely used in industries requiring high electrical and thermal performance. Typical applications include:

The Aerospace Industry Is Renowned For Its Pursuit Of Cutting-Edge Technology And Uncompromising Safety Standards. In This Demanding Environment, Forgings Stand Out As Key Elements That Contribute To The Reliability And Performance Of Aircraft.

Forgings Play A Crucial Role In The Mining Industry, Providing Essential Components That Ensure Efficiency, Safety, And Durability In Various Mining Operations.

Oil And Gas Industry Is A Cornerstone Of The Global Energy Supply, Characterized By High Demands For Efficiency, Safety, And Resilience.

With The Development Of The Energy And Electronics Industries, The Demand For Forgings Continues To Increase. Especially In The Field Of Renewable Energy, Such As Wind Power Generation And Nuclear Power Generation, The Application Of Forgings Will Be Further Expanded.

From the enormous torque transmitted by propeller shafts to the constant hydrodynamic forces experienced by rudder systems, every component must meet the highest standards of strength, reliability, and precision. This is where marine forgings come in – providing high-performance forged products designed for durability and to extend the life of your vessel.

Pressure Vessels Are Vital Factors In A Large Vary Of Industries, From Chemical Processing To Electricity Production. Choosing The Proper Vessel Now Not Solely Ensures Operational Effectivity However Additionally Immediately Affects Safety, Compliance, And Long-Term Cost-Effectiveness.

OUR CUSTOMERS