What Is the Forging Process?

The forging method is a imperative metal-shaping approach the place compressive forces are utilized to a stable workpiece to reap the preferred geometry. Unlike casting, which includes melting, forging reshapes the fabric in its stable state, ensuing in stronger, greater durable, and defect-resistant components.

This method has been practiced for centuries and stays imperative these days in industries like aerospace, automotive, oil & gas, electricity generation, heavy equipment, and defense. Modern forging tactics mix normal craftsmanship with superior equipment and computer-controlled systems, making sure precision and repeatability.

Types of Forging Process by means of Die Configuration

The preference of die setup determines how the forging method is performed:

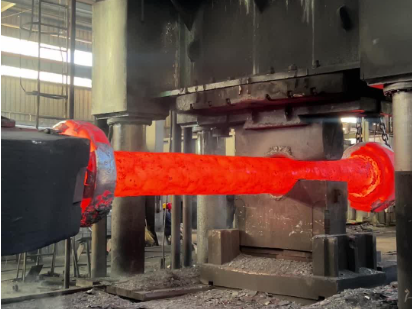

Open Die Forging Process

In open die forging, the workpiece is positioned between flat or easy dies that do now not enclose it fully. The steel flows freely without the place constrained by way of the die, making it appropriate for massive customized forgings, shafts, rollers, and rings.

Impression Die Forging Process

Also regarded as closed die forging, this technique makes use of dies with cavities that absolutely form the metallic underneath excessive pressure. Excess cloth (flash) is later trimmed off. It is extensively used for automotive, aerospace, and equipment components that require complicated geometries.

Rolled Ring Forging Process

This specialised forging technique produces seamless rings via piercing a round billet and rolling it underneath pressure. The end result is high-strength rings used in bearings, turbines, tools blanks, and aerospace structures.

Upset and Press Forging Process

Other strategies such as upset forging (increasing the cross-section of phase ends) and press forging (gradual deformation below constant pressure) are utilized for bolts, shafts, and factors requiring uniform deformation.

Types of Forging Process by means of Temperature

The forging technique is additionally labeled primarily based on temperature conditions:

Hot Forging Process: Performed above the metal’s recrystallization temperature, permitting convenient deformation and disposing of pressure hardening. It produces amazing ductility however may additionally require scale removal.

Warm Forging Process: Conducted between warm and bloodless ranges, it balances energy retention with decreased forging loads.

Cold Forging Process: Done at or close to room temperature, this approach achieves particular tolerances and clean finishes however requires greater forming forces.

Forging Process Steps Explained

A fashionable forging system workflow follows these stages:

Material Selection and Cutting – Choosing billets, bars, or ingots of the proper grade and reducing them to length.

Heating (if applicable) – Raising the metallic to the forging temperature in furnaces or induction heaters.

Forging / Deformation – Applying compressive forces with the aid of hammers, presses, or rolling mills.

Trimming and Flash Removal – Removing extra cloth from closed die forgings.

Heat Treatment – Processes like quenching, tempering, and annealing to refine mechanical properties.

Surface Treatment and Machining – Grinding, shot blasting, or CNC machining for dimensional accuracy.

Inspection and Quality Control – Checking hardness, toughness, grain flow, and dimensional accuracy.

Final Finishing and Delivery – Packaging solid components for cargo to customers.

Advantages of the Forging Process

Superior Mechanical Properties: The grain shape flows alongside phase geometry, growing fatigue resistance.

Consistency and Reliability: Forged components are free from inner voids frequent in castings.

Material Efficiency: Less waste in contrast to machining from stable stock.

Wide Material Compatibility: Steel, stainless steel, aluminum, titanium, and nickel alloys are all frequently forged.

Scalability: From single customized forgings to high-volume manufacturing runs.

Limitations of the Forging Process

High Tooling Costs: Especially for affect die forging, the place dies are expensive.

Design Restrictions: Some thin-walled or difficult geometries may also be challenging to forge.

Equipment Investment: Requires heavy presses, hammers, or ring-rolling mills.

Surface Finishing Needs: Forged components frequently require post-machining.

Applications of Forging Process in Modern Industry

Automotive: Crankshafts, connecting rods, gears, axles, and wheel hubs.

Aerospace: Landing gear, turbine discs, engine shafts, and structural rings.

Oil & Gas: Pressure vessel components, drilling subs, flanges, and valves.

Power Generation: Turbine rotors, shafts, generator parts, and massive rings.

Heavy Machinery: Mining equipment, marine shafts, and development parts.

Choosing the Right Forging Process for Your Needs

When choosing a forging process, consider:

The required section dimension and geometry.

Mechanical property necessities (strength, toughness, fatigue resistance).

Production quantity (prototype, medium batch, or mass production).

Material type and forging temperature range.

Cost effectivity versus overall performance requirements.

By perception the variations amongst warm forging, bloodless forging, open die forging, closed die forging, and rolled ring forging, producers and consumers can choose the most environment friendly procedure for their applications.