1. What Is Bar Stock? Understanding the Basics of Steel Bar Stock, Aluminum Bar Stock, and More

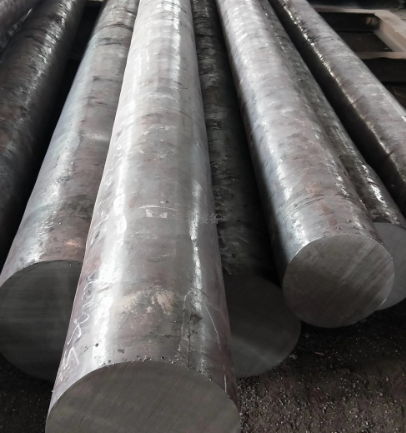

Bar stock—also known as metal bar stock, steel stock bar, aluminum bar stock, stainless steel bar stock, carbon steel bar stock, or simply “bar”—refers to raw metal materials processed into standardized shapes for machining, forging, drilling, and manufacturing.

Common forms include round bar stock, square bar stock, hex bar stock, hexagonal bar stock, and flat bar stock.

In industries such as oil & gas, petrochemicals, aerospace, automotive, and heavy machinery, bar stock serves as the primary material for producing precision components, flanges, drilling tools, shafts, fasteners, and structural parts.

At TIP TOP, we supply a full range of steel bar stock, aluminum bar stock, titanium bar stock, stainless bar stock, brass bar stock, bronze bar stock, and specialized alloys to meet demanding operating conditions.

2. Types of Bar Stock Materials: From Carbon Steel Bar Stock to Titanium Bar Stock

2.1 Carbon Steel Bar Stock

Carbon steel is the most widely used bar stock material due to its strength, affordability, and machinability. Common grades include:

4140 bar stock – high strength, excellent hardness, widely used in oilfield drilling tools and tool joints

4130 bar stock – good weldability and toughness

carbon steel bar stock (A36, 1045, 1020, etc.) – general machinery and structural components

Applications: drilling subs, collars, flanges, pressure vessel parts, shafts, heavy equipment components.

2.2 Alloy Steel Bar Stock

Alloy bar stock provides improved performance in high-pressure and high-load environments.

4140 bar stock

4340 alloy steel

8620 alloy steel

Applications: high-strength wellhead components, downhole tools, heavy forged components.

2.3 Stainless Steel Bar Stock & Stainless Bar Stock

Stainless bar stock includes:

304 stainless steel bar stock

316 stainless bar stock

410/420 martensitic stainless bar

Applications: corrosion-resistant flow control parts, valves, pump components, offshore equipment.

2.4 Aluminum Bar Stock

Aluminum bar stock is lightweight, corrosion-resistant, and easy to machine. Popular grades include:

6061 bar stock / 6061-T6 aluminum bar stock

7075 aluminum bar stock – aerospace-grade hardness and fatigue resistance

aluminum flat bar stock

aluminum bar stock sizes (custom cut available)

Applications: aircraft components, lightweight structural parts, instrumentation housings.

2.5 Specialty Bar Stock Materials

TIP TOP also supplies:

titanium bar stock – extreme strength-to-weight ratio

copper bar stock – excellent thermal and electrical conductivity

brass bar stock / bronze bar stock – corrosion-resistant marine and mechanical parts

cast iron bar stock – wear-resistant applications

3. Bar Stock Shapes and Profiles for Industrial Manufacturing

3.1 Round Bar Stock

Used for shafts, pins, drilling tools, mandrels, valves, tool joints.

3.2 Square Bar Stock

Ideal for structural machining and machinery frames.

3.3 Hex Bar Stock / Hexagonal Bar Stock

Preferred for fasteners, nuts, and precise oilfield tool components.

3.4 Flat Bar Stock / Aluminium Flat Bar Stock

Common in brackets, support structures, pressure parts.

TIP TOP provides custom cutting, forging, heat treatment, and machining services to convert bar stock into finished industrial components.

4. Bar Stock vs Forgings: Which Is Better for Oilfield and Heavy-Industry Applications?

Many customers compare bar stock vs forging when selecting raw materials.

When to Choose Bar Stock

Complex machining is required

Rapid prototyping or small batch production

Lower cost for simple shapes

Uniform properties along the entire bar

When to Choose Forgings

High-impact or high-pressure working conditions

Higher mechanical strength and grain flow

Large components with critical load-bearing performance

Oilfield drilling tools, casing head, wellhead housings, spools, and pressure-containing parts

TIP TOP offers both forging and bar stock solutions, providing balanced options depending on technical requirements.

5. Industrial Uses of Bar Stock: Oilfield, Wellhead, Machinery, and Aerospace

Bar stock is essential across multiple industries:

Oilfield & Drilling

drill collars

stabilizers

casing head and wellhead components

subs, mandrels, connectors

valve bodies and pump housings

Heavy Machinery

shafts, rollers, support arms

wear-resistant machine parts

Aerospace

7075 aluminum bar stock for aircraft strength-critical parts

Energy & Petrochemicals

pressure vessel flanges

heat exchanger parts

pump components

Marine

bronze bar stock for anti-corrosion applications

TIP TOP supplies bar stock in multiple grades with full traceability and material certification.

6. Why Choose TIP TOP as Your Trusted Supplier for Metal Bar Stock Materials?

As a professional oilfield drilling materials and forged components manufacturer, TIP TOP provides:

✓ Complete Range of Bar Stock Materials

Including steel bar stock, stainless steel bar stock, aluminum bar stock, brass and bronze bar stock, titanium bar stock, and custom alloys.

✓ Precision Cutting, Forging & CNC Machining

We deliver ready-to-use components customized to your drawings.

✓ Strict Quality Control

Ultrasonic testing

Hardness & tensile testing

Chemical composition analysis

Heat treatment traceability

✓ Fast Delivery & Global Service

Weassistoilfield operators, wellhead equipmentproducers, heavy machineryfactories, aerospacevendors, and energyinitiativesglobally.

7. Conclusion:Top-QualityBar Stock Materials for YourProductionRequirements

Whether you need 4140 bar stock for drilling tools, 7075 aluminum bar stock for aerospace parts, or stainless steel bar stock for corrosion-resistant components, TIP TOP offers reliable material solutions backed by strong production capabilities and strict quality standards.

Weaidclientsinchoosingtheappropriatematerial,maximizingperformance, andloweringtotalfabricationexpenses.