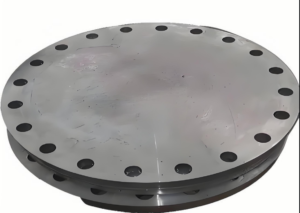

Description

This makes forged blocks essential for industries requiring exceptional durability, such as oil & gas, marine engineering, chemical processing, hydraulic machinery, and energy equipment.

At TIP TOP Forging, we specialize in manufacturing reliable, high-performance stainless steel blocks through advanced forge stainless steel technology and strict quality control.

Material Grades Available for Forged Stainless Steel Block Products

TIP TOP offers a wide range of stainless steel materials suitable for critical applications. Among them, 304 stainless steel block and 316 stainless steel block are the most commonly used.

304 Stainless Steel Block (Forged)

- Ideal for general industrial parts

- Good corrosion resistance and machinability

- Cost-effective for high-volume machining

- Suitable for food, machinery, construction, and general equipment manufacturing

316 Stainless Steel Block (Forged)

- Enhanced corrosion resistance due to Mo content

- Excellent performance in chemical and marine environments

- Preferred for forging 316 stainless steel components

- Used in offshore equipment, pumps, valves, and high-pressure systems

TIP TOP can also supply 316L, 2205 duplex, and other specialty stainless grades depending on customer requirements.

TIP TOP Custom Stainless Steel Forging Capabilities for Forged Stainless Steel Block

As an experienced manufacturer, TIP TOP provides complete custom stainless steel forging solutions tailored to customer drawings and specifications.

Our Forging Capabilities

Weight: 50 kg – 20 tons

Max dimensions: large rectangular, square, and stepped blocks

Manufacturing methods: open-die forging, precision forging

Heat treatment: normalizing, quenching, tempering, solution treatment

Machining: rough machining or final machining (per customer needs)

By using advanced open-die presses and forging manipulators, we ensure that each forged stainless steel block has uniform structure and stable mechanical properties.

Key Features of TIP TOP’s Forged Stainless Steel Block

A forged stainless steel block produced by TIP TOP provides:

- High mechanical strength for heavy-duty performance

- Excellent corrosion resistance for harsh or chemical environments

- Superior impact toughness due to directional grain flow

- Zero casting defects, ensuring long service life

- Stable machinability, suitable for CNC or deep machining

- Dimensional accuracy after heat treatment and forging control

Compared to standard stainless steel block, a forged variant offers increased durability and reliability, making it the preferred choice for precision industrial components.

Applications of Forged Stainless Steel Block in Modern Industries

TIP TOP’s forged blocks are widely used in:

- Valve bodies & pump housings

- Marine shafts, couplings & offshore structures

- Oil & gas tools and pressure equipment

- Hydraulic cylinder blocks & manifolds

- Heat-resistant and corrosion-resistant components

- Chemical and food processing equipment

- Heavy machinery and mechanical base parts

Wherever mechanical strength and corrosion resistance are essential, a forged stainless steel block delivers dependable performance.

Why Choose TIP TOP as Your Forged Stainless Steel Supplier?

TIP TOP Forging is a trusted forged stainless steel supplier with decades of experience serving global industries.

What We Offer

Professional forging of 304, 316, and other stainless grades

Large block forging with consistent mechanical properties

Complete heat-treatment solutions for enhanced performance

UT, MT, RT, and mechanical testing as required

Short lead times and stable international shipping

OEM customization per drawing

Our expertise in forge stainless steel technology allows us to maintain high precision and exceptional consistency across all forged stainless steel block products.

How to Select the Right Forged Stainless Steel Block for Your Application

To choose the correct forged block, consider:

Required corrosion resistance (304 vs 316/316L)

Mechanical load and fatigue environment

Temperature conditions

Pressure rating

Machining allowance

Shape requirements (square, rectangular, stepped block, etc.)

Required certification or standard

TIP TOP provides technical consultations to help you select the most suitable forging grade and production route.

Request a Quote for Custom Forged Stainless Steel Block Solutions

Whether you need a 304 stainless steel block, 316 stainless steel block, or tailor-made custom stainless steel forging, TIP TOP Forging delivers competitive pricing, stable quality, and fast production cycles.

Contact us today for a detailed quotation and engineering support for your forged stainless steel block requirements

Reviews

There are no reviews yet.