What a Metal Forged Means in Modern Manufacturing

The term metal forge refers to a controlled industrial environment where forging metal is performed through heat and pressure to create stronger, more reliable components. Compared with casting or machining, forged metal offers superior grain structure, higher fatigue resistance and exceptional durability—qualities essential for heavy-duty and safety-critical applications.

Many buyers search for “metal forge near me” or “metal forging companies” because forged metals remain fundamental in aerospace, oil & gas, mining, construction, power generation and transportation industries. Whether the requirement is for custom forged metal shapes or large metal forgings, forging metals continues to be one of the most dependable manufacturing approaches for high-performance parts.

Metal Forged Processes and How They Shape Industrial Components

Understanding the Metal Forging Process

The metal forging process typically involves heating the workpiece until it reaches a suitable forging temperature, followed by deformation through hammering, pressing or rolling. This process aligns the internal grain, enhancing mechanical strength. Buyers frequently ask what is forging metal or how to forge metal, and the core principles remain consistent across all metal forge operations:

Controlled heating

Rapid deformation

Refined grain structure

Stress distribution optimization

Dimensional finishing

TIP TOP applies these principles to manufacture both precision forged metals and large-scale industrial forgings.

Open-Die Metal Forge Method

Open-die forging metal is ideal for oversized components such as shafts, rings, blocks and cylinders. This method provides excellent internal soundness and is suitable for industries requiring high structural integrity.

Closed-Die Metal Forge Method

Closed-die forging metals is preferred for complex geometries and mass-production parts. It offers tight tolerances, consistent repeatability and minimal machining allowances—perfect for automotive, aerospace and machinery sectors.

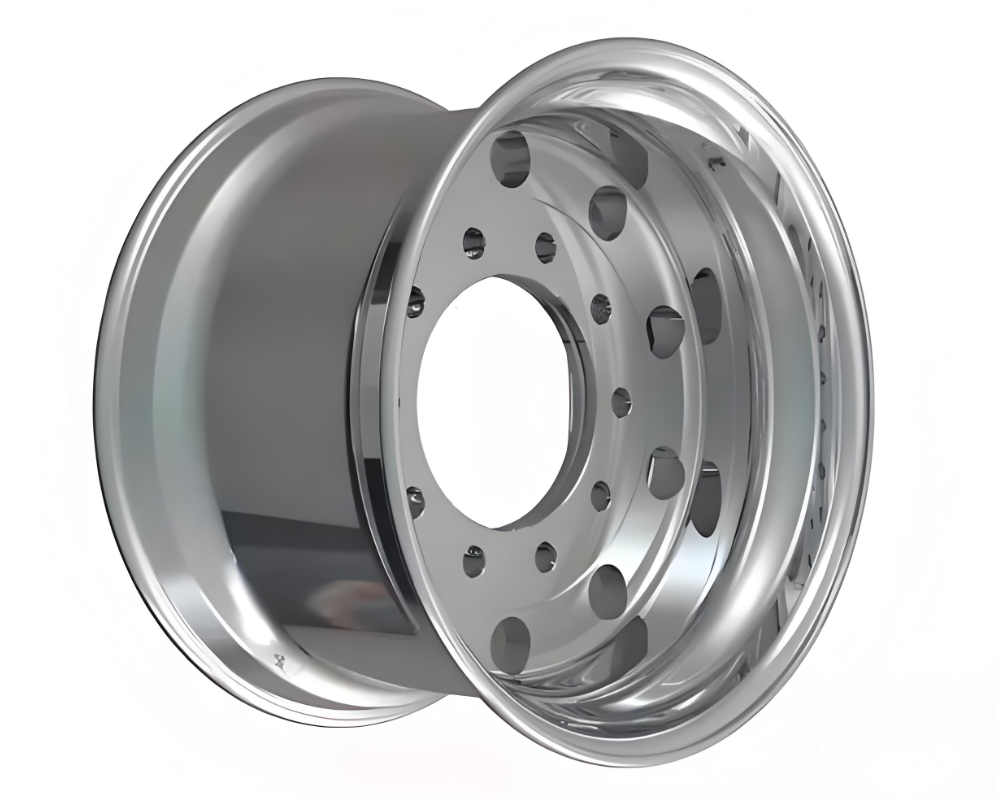

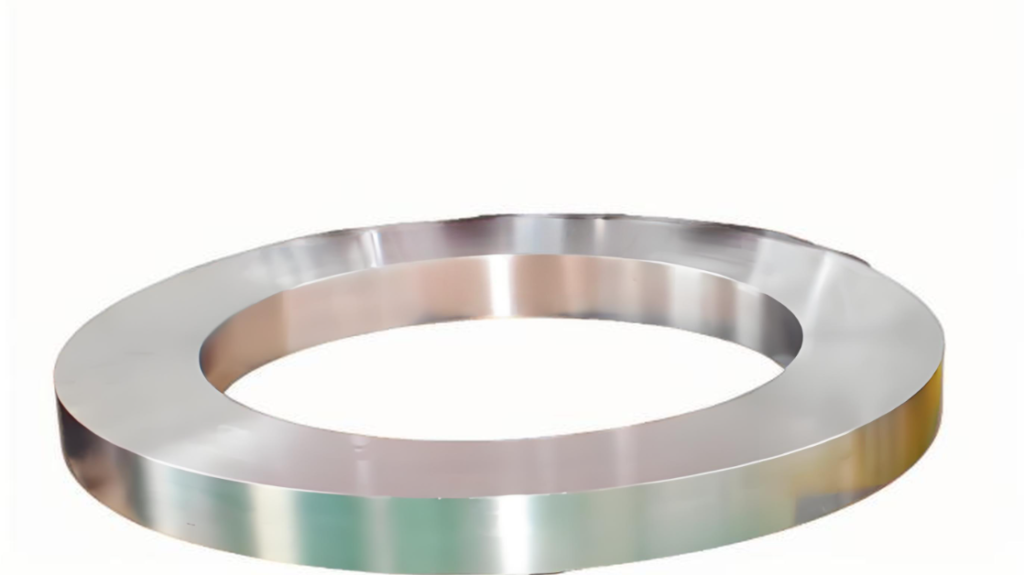

Ring Rolling in Metal Forge Operations

Ring rolling is widely used for producing forged metal rings with high strength and low weight. These components appear in bearings, gear systems, turbine engines and other rotating equipment.

Metal Forge Finishing and Post-Processing

Forge metal finishing includes heat treatment, machining, straightening, surface finishing and NDT inspections. Proper finishing ensures the forged metal meets dimensional and performance requirements.

What Metals Can Be Forged in a Metal Forge Facility

A professional metal forge company can work with various materials. At TIP TOP, our custom metal forging services cover a wide selection of metals forging options:

Titanium forgings

Copper and brass forged metals

Understanding what metals can be forged helps buyers determine the correct grade for their application.

Applications of Forged Metal Across Industrial Markets

The metal forging market plays an essential role in producing mission-critical components, including:

Industrial shafts and axles

Flanges and forged rings

Pressure vessel components

Mining wear parts

Aerospace structural pieces

Automotive hubs and crankshafts

Oilfield drilling tools

Engineering teams rely on forged in metal components because they provide longer service life and improved safety margins under extreme conditions.

Metal Forged Tools and Equipment Used in Forging Metals

Metal forging tools vary depending on component size and complexity. Common equipment includes:

Hydraulic forging presses

Pneumatic forging hammers

Ring-rolling mills

Manipulators and handling systems

Furnaces and controlled heating systems

Dies for custom metal forgings

Some hobbyists search for metal forge kit or metal forge for sale, but industrial-grade forging facilities require far more advanced equipment to maintain consistency, safety and quality.

Choosing Metal Forging Companies for High-Quality Production

When evaluating metal forging companies or metal forging suppliers, consider the following:

Material range and forging capacity

Experience in custom metal forging

Capabilities in large and small metal forgings

Quality management and certifications

Machining and finishing capabilities

Supply stability and delivery reliability

A professional metal forger should also offer engineering support for product optimization, reducing cost and improving performance.

TIP TOP — A Trusted Metal Forge Company for Custom Forgings

As a specialized forging manufacturer, TIP TOP Forging provides complete custom metal forging services for global industries. Our facility integrates open-die forging, closed-die forging, ring rolling and precision machining, enabling us to produce a wide range of forged metals from small precision parts to large industrial components.

Custom Metal Forging Manufacturers with Multi-Industry Capabilities

TIP TOP supplies:

Custom metal forgings for oil & gas

Precision forged metal aerospace components

Forging metals for mining machinery

Large forged blocks, rings and bars

Custom forged metal shapes for mechanical systems

Our engineering team supports material selection, forging route planning and heat-treatment optimization.

Reliable Metal Forging Services with International Quality Standards

All products undergo comprehensive quality inspection, ensuring what is forged metal in our facility meets demanding performance expectations. Standard tests include:

Ultrasonic testing (UT)

Hardness testing

Mechanical testing

Chemical composition verification

Dimensional inspection

Our goal is consistent quality, stable supply and long-term customer confidence.

Why the Metal Forged Market Continues to Expand

The global metal forging market is driven by:

Increased demand for high-strength components

Infrastructure development and heavy machinery needs

Growth in aerospace, automotive and energy industries

Rising adoption of custom forged metal shapes

Preference for longer-lasting forged metals over cast alternatives

TIP TOP continues to upgrade equipment and expand capacity to meet long-term market growth.

Conclusion — Partner with TIP TOP for Professional Metal Forged Solutions

Metal forging remains a core manufacturing process for producing strong, reliable and performance-driven components. Whether you require custom metal forging services, large industrial metal forgings or engineered forged metals, TIP TOP provides comprehensive solutions backed by advanced equipment and professional technical expertise.

We are ready to support your next project with stable quality, flexible customization and dependable delivery.