What Is a Forging Ring and Why It Matters in Modern Industries

A forging ring—often referred to as a forging ring component, ring of forging, forged ring, or ring forging—is a circular metal product shaped through high-pressure deformation processes. Compared with casting or fabrication, forging ring manufacturing delivers superior strength, uniform grain flow, and excellent performance under high loads and extreme conditions. Whether it is a forged steel ring, forged carbon ring, forged carbon fiber ring, or forge titanium ring, the integrity and reliability of these components make them critical in aerospace, energy, mining, machinery, and industrial equipment.

At TIPTOP Forging, our ring forgings are engineered to meet demanding performance needs. With decades of forging expertise, we manufacture high-precision forge rings and ring rolling forging products customized for different materials, diameters, and working environments.

Key Advantages of Forging Ring Components

Forged ring metals are among the most liked products because of their very strong mechanical characteristics. Firstly, it refines the grain structure thus giving the metals utmost strength without any weak points through the forging ring process. This results in the excellent resistance of the metals to fatigue, impact, and vibration. Besides that, forged rings e.g., forged steel rings, forged carbon fiber rings, titanium forge rings, have uniform metallurgical quality, thus, can be trusted to be used in high-temperature and high-pressure conditions.

These advantages of forged rings explain why they are chosen by industries as components in heavy-duty jobs such as wind turbine hubs, bearing races, industrial flanges, pressure vessel components, and aerospace structural rings.

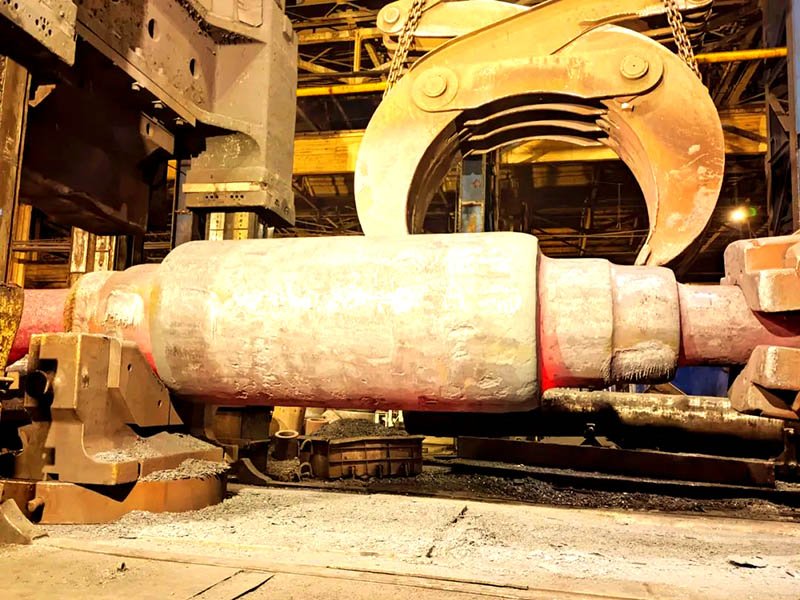

How Ring Rolling Forging Produces Stronger and Larger Rings

Ring rolling forging or seamless ring rolling forging is a method that lead to the production of forged rings having outstanding strength-to-weight ratios. The operation of this method consists of rolling a pre-forged ring between a pair of dies, thus, the ring’s diameter is extended while the thickness is reduced. Uniformity, precision, and good structural strength are the features of the product after this process.

Ring rolling forging is more productive and efficient in terms of material use than open-die forging. TIPTOP Forging is equipped with state-of-the-art rolling mills that can produce forging ring components of a whole range of sizes, from small precision rings to large forged rings of several meters in diameter.

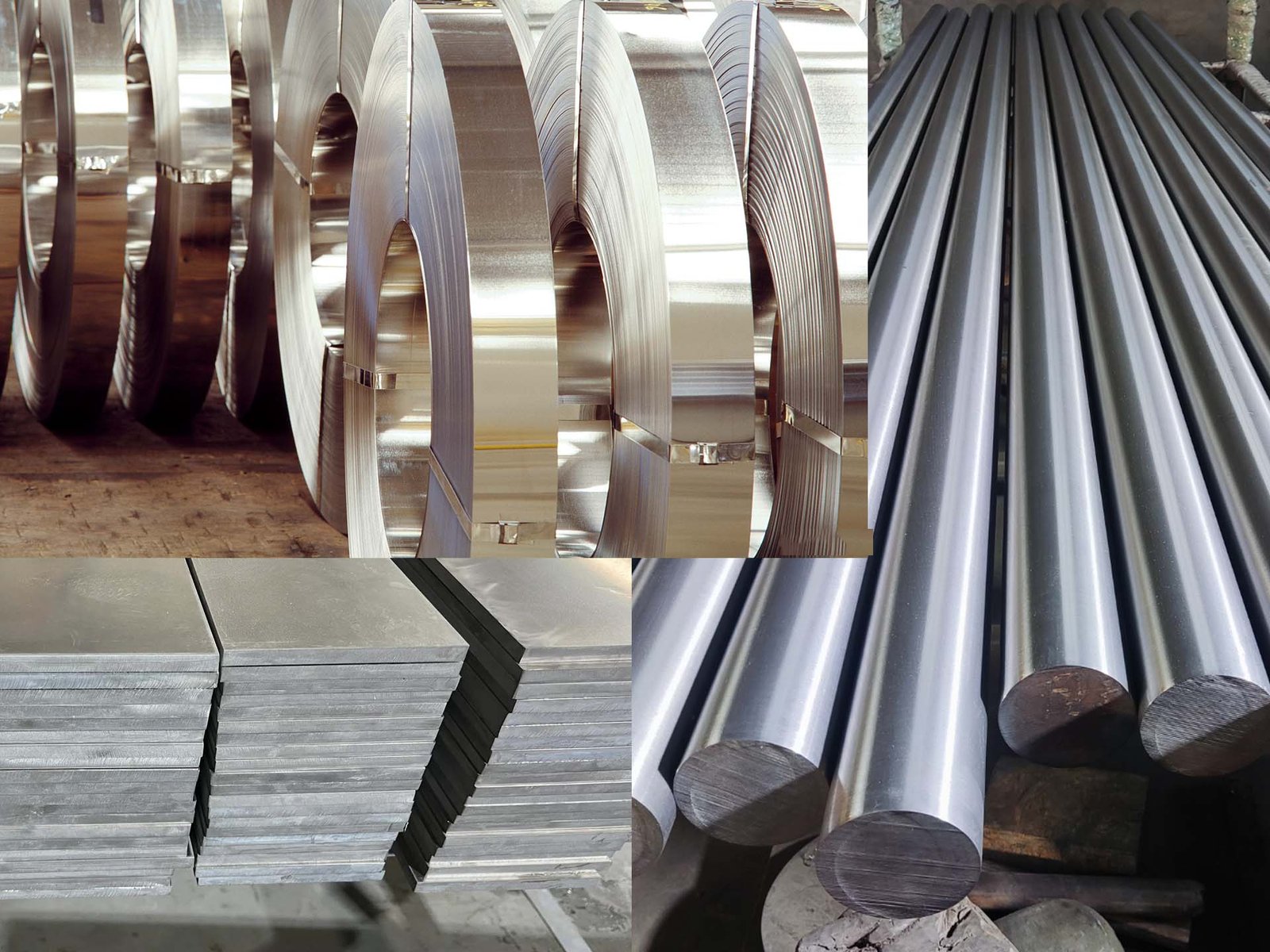

Materials Used in High-Performance Forge Ring Manufacturing

Materials for forging ring set-ups can be chosen from the following list, depending on the application:

Stainless steel → Corrosion-resistant forged steel rings for the marine and chemical industries.

Titanium alloys → Lightweight, high-strength forge titanium ring components for aerospace projects.

High-temperature alloys → For turbine and other extreme-environment machines.

TIPTOP Forging has a range of materials to choose from to meet the performance requirements of your project.

Inter-industry Applications of Forging Ring Products

Industries that are ring forging components users are mainly from the sectors that are characterized by high durability and reliability needs. Their main functions are:

Aerospace: Engine rings, structural rings, and forged titanium rings.

Oil & Gas & Petrochemical: High-pressure sealing rings, connector rings, and pipeline equipment.

Wind Power & Energy: Turbine bearing rings, tower flange rings, and generator rings.

Industrial Machinery: Gear rings, bearing races, and forged ring couplings.

Automotive & Heavy Vehicles: Transmission rings, hubs, and axle components.

The ring of forging products is one of the very few that can perform excellently in situations of operational stability and long service life needs.

Why Choose TIPTOP Forging for Forge Rings and Ring Forging Solutions

TIPTOP Forging is a leading forging manufacturer in China specializing in forging ring production for global customers. Our advantages include:

Advanced forging equipment including open-die presses and seamless ring rolling forging mills.

Strict quality control covering material testing, ultrasonic inspection, mechanical testing, and chemical composition analysis.

Customized production for forge rings, forged carbon fiber rings, forged steel rings, forged carbon rings, and titanium forged components.

Engineering support helping customers optimize materials, sizes, and manufacturing processes.

Global supply capability ensuring stable production and fast delivery for large batches or one-off custom forged ring projects.

Our forging capabilities allow us to produce high-precision ring forgings from 50 mm to several meters in diameter with consistent quality.

Conclusion: Your Trusted Partner for Reliable Forging Ring Manufacturing

Forging ring components play a vital role in countless industrial applications, providing exceptional durability, structural integrity, and performance stability. Whether you need forged rings, ring rolling forging, forged carbon rings, forged steel rings, or customized titanium forge ring products, TIPTOP Forging delivers solutions engineered for reliability.

By combining advanced technology, professional craftsmanship, and strict quality standards, TIPTOP Forging stands as a trusted manufacturer for customers seeking high-performance ring forging products tailored to their application needs.