What Are Oil and Gas Forgings

Oil and gas forgings are metal parts that have been specifically created for being used in oilfield drilling, production, pipeline, and petrochemical systems. In comparison to cast or welded components, forgings in the field of oil and gas give a better grainy structure, more mechanical strength, and a better capability in fighting the pressures, impacts, and fatigue.

Most of the time, equipment used in oil and gas operates under high pressure, a high temperature, or in the presence of a corrosive environment. That’s why forging oil and gas components is the most satisfying method for manufacturers to produce safe load-bearing and pressure-confining parts.

Why are Oil and Gas Forgings Used in Harsh Oilfield Conditions?

The oil and gas forging approach is mainly taken to uplift the internal material density and to get rid of casting defects such as porosity or shrinkage. This leads to the development of elements with steady mechanical characteristics and a higher level of safety against structural collapse.

Oil and gas forgings are widely selected for oilfield applications due to their ability to withstand:

- High internal pressure

- Cyclic mechanical loads

- Temperature fluctuations

- Harsh working environments

These characteristics make forge oil and gas solutions suitable for long-term operation in drilling and production systems.

Key Applications of Oil and Gas Forgings

Oil and gas forgings are used across multiple stages of oil and gas operations, from drilling and well control to transportation and processing. Forged components play a critical role in maintaining system integrity and operational safety.

Common applications include:

- Forged valves for oil and gas systems

- Large forging for oil and gas pipe fittings

- Forged flanges, connectors, and pressure components

- Forged shafts, hubs, and mechanical parts

Each oil and gas forging application requires precise control of material properties and dimensional accuracy.

Forged Valves and Pressure Components for Oil and Gas Systems

From various parts to components, every part required for an oil and gas system including the pipes that carry the oil or gas, the different units that collect or process the gas or the oil, and the storage or distribution facilities through which the oil and gas are brought to the market are ECO friendly.

In a few smaller and lighter models the liquid propanepowered forklifts are used: for indoor use in warehouses where electric forklifts are not allowed to be used, for outdoor use on construction sites and in municipal work such as gardens and parks, etc.

Several sectors have been impacted in terms of regulations and financial obligation. How companies re-organize, alleviate the impact of that obligation and also comply with new regulations have been the biggest concerns in the context of energy efficiency and carbon footprint of their operations and transport systems, e.g. air cargo, cruise ships, or buses.

The ceramic towers were designed to take advantage of the temperature gradient between the vapor and air for the separation of the CO2 produced by fossil fuel burning plants. This process is intended to produce CO2 with higher purity than common power plants that will be available for industrial use.

The dense grain flow achieved during forging helps reduce the risk of leakage, cracking, and deformation in high-pressure oilfield systems.

Applications of Forged Flanges and Pipe Fittings in Oil and Gas

Applications of forging flange in the oil and gas industry require components capable of maintaining tight seals under extreme pressure and mechanical stress. Oil and gas forgings are commonly used for flanges, elbows, tees, and connectors in pipelines and processing facilities.

Large forging for oil and gas pipe fittings provides improved load distribution and resistance to fatigue, making forged components suitable for critical pipeline connections and pressure systems.

Materials Commonly Used in Oil and Gas Forgings

Oil and gas forgings are produced using carefully selected carbon steels, alloy steels, and stainless steels to match specific service requirements. Typical materials include ASTM A105, A182 F-series, A350, A694, and other specifications commonly used in oil and gas equipment.

Through controlled heat treatment and strict inspection procedures, oil and gas forgings achieve the required strength, toughness, and corrosion resistance.

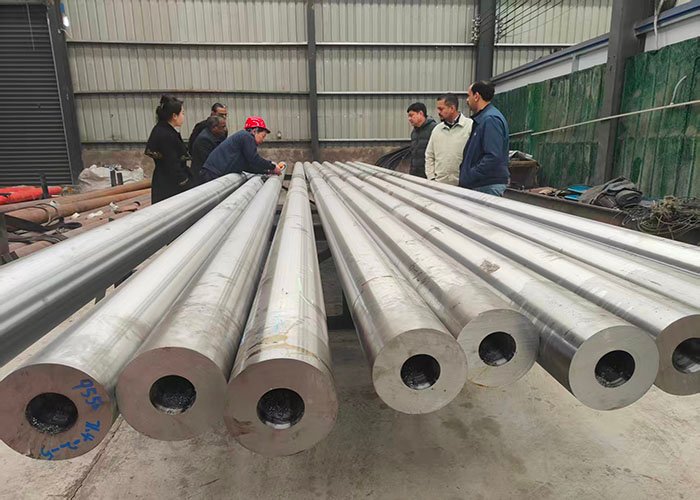

TIP TOP as a Supplier of Oil and Gas Forgings

TIP TOP Forging prides itself on offering customized oil and gas forgings for the drilling, pipeline, and pressure equipment applications of the oil and gas industry.

We supply:

- Forged valves and pressure parts

- Forged flanges and pipe fittings

- Large oil and gas forgings

- Custom forging oil and gas solutions

Steady and top-quality materials, efficient material traceability, and the consistent mechanical performance are among the agendas of TIP TOP. The above that results in the long-term support of your need for oil field operations.

Quality Control for Oil and Gas Forgings

Quality control is essential for oil and gas forgings due to the demanding service conditions. TIP TOP applies comprehensive inspection procedures including chemical composition analysis, mechanical testing, ultrasonic testing, and dimensional inspection.

These measures ensure every oil and gas forging meets applicable industry standards and customer specifications before delivery.

Conclusion: The Role of Oil and Gas Forgings in Oilfield Equipment

Oil and gas forgings are a fundamental part of modern oilfield equipment and systems. Their superior strength, durability, and reliability make them suitable for critical applications such as valves, flanges, pipe fittings, and pressure components.

By working with an experienced forging oil and gas supplier like TIP TOP, customers can obtain reliable forged solutions designed to perform consistently under demanding oilfield conditions.