Description

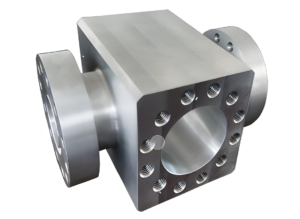

Overview of Forged Blocks for Valve Body Manufacturing

TIPTOP forged valve body blocks are the primary pressure parts for oil & gas, high-integrity fluid control systems, and energy industries. Compared with cast blocks, one can consider the creation of a forged block as a product of controlled deformation which, in turn, results in a denser and directional grain structure and hence, strength, toughness, and fatigue resistance properties are improved considerably.

In TIPTOP, we use only quality steel billets for every forging block for valve body application. The production of these forged steel blocks is also carefully guided by international standards such as API 6A, API 16C, and others to structurally, dimensionally and safety-wise, prepare them for reliable operation in the demanding environment of the wellhead and pressure control.

Why Forsed Steel Blocks Are Perfect for Valve Bodies

Outstanding Mechanical Integrity Under Pressure

One of the uses of forged blocks as valve bodies is to take high internal pressure, cyclic loading, and pressure fluctuations that may occur suddenly. The internal grain flow of the forged block gets along with the shape of the component, through hot forging, so the typical problems of shrinkage cavities, porosity, and segregation which occur in the area of the casting are avoided. That is why forged valve bodies have a much lower risk of failure in critical pressure zones.

Reliable Machining to Achieve Precision Valve Components

Uniform microstructure and controlled residual stress of a forged steel block make the latter very suitable for CNC machining. Valve body manufacturing the processes of drilling, milling, boring, and sealing surface machining can be performed quickly, dimensions can be stable, and a high-quality surface finish can be achieved, all during the same machining cycle.

Improved Resistance to Hard Conditions Such As Impact, Fatigue, and Sour Service

Valve bodies have the disadvantage of vibrations, frequent opening and closing, and also the presence of harsh media such as H₂S and CO₂. Forged blocks have superior impact toughness and fatigue resistance, thus, they can be used without hesitation in sour gas wellheads and high-pressure manifold systems. Through accurate heat treatment control, forged valve bodies are capable of satisfying NACE MR0175 / ISO 15156 hardness and microstructure requirements in a reliable manner.

Forged Valve Body Manufacturing Process Using Forged Blocks

Material Selection and Billet Preparation

The manufacturing process begins with the selection of appropriate carbon steel or alloy steel billets based on valve pressure rating, temperature, and service environment. Each billet undergoes homogenization treatment before cutting to ensure consistent chemical composition throughout the forging block.

Heating and Forging Operations

Billets are heated to the optimal forging temperature to improve plasticity and reduce deformation resistance. Depending on valve size and design, free forging or die forging is applied to form the rough valve body shape. In some forming stages, swage block in forging techniques may be used to control cross-section and improve material flow in localized areas.

Heat Treatment and Quality Control

After forging, the valve body block is subjected to normalizing, quenching, and tempering to achieve the required mechanical properties. Non-destructive testing such as UT, MT, or MPI is then performed to ensure the forged block is free from internal or surface defects before further machining.

Final Machining and Acceptance

Precision machining brings the forged valve body to its final dimensions, followed by surface treatment as required. Final inspection and acceptance are conducted strictly according to API 6A and customer technical specifications before delivery.

Typical Applications of Forged Blocks Used as Valve Bodies

Forged valve body blocks are widely used in critical pressure control systems where failure is not an option. Typical applications include blowout preventer (BOP) systems, wellhead Christmas tree main and wing valves, high-pressure fracturing manifolds, choke and kill manifolds, and deepwater or ultra-deepwater oil and gas production equipment. These environments demand the structural reliability that only a forged steel block can provide.

Forged Valve Bodies vs Cast Valve Bodies

Although forged valve bodies generally have a higher initial cost than cast alternatives, the difference lies in long-term performance and risk control. Forged blocks offer significantly lower failure rates, longer service life, and superior performance in high-pressure, high-temperature, or corrosive environments. For critical valve applications, the use of forged blocks reflects a design philosophy focused on prevention rather than repair.

Reliability in Sour Gas and Critical Service Conditions

Forged valve bodies demonstrate clear advantages in resisting sulfide stress corrosion cracking. The dense and uniform microstructure of a forged block allows for precise hardness control during heat treatment, reducing crack initiation risks and ensuring compliance with sour service standards. This makes forged valve bodies the preferred solution for high-risk operating conditions.

Reviews

There are no reviews yet.