The main shaft is a versatile, indispensable mechanical part integral to gearboxes, car transmissions, wind turbines, and heavy industry.

It mainly transmits the torque, holds and supports the rotating parts and keeps the components aligned even under heavy load and continuous operation.

Therefore, the total system’s efficiency, durability, and safety depend largely on the performance of the main shaft.

If you understand the function of a main shaft, how it is different from other shafts, and what its manufacturing process is, you will be in a better position to help both engineers and equipment buyers in making design and sourcing decisions.

What Is a Main Shaft in Mechanical Systems

In mechanical engineering, a main shaft is basically the first/primary shaft which rotates and through which power is transmitted from a driving source to downstream parts.

Depending on the application, it can also be known as a main shaft in a gearbox assembly or main shaft transmission system.

What does a main shaft do in a gearbox or transmission system?

In a gearbox, the main shaft is the link between the input and output power paths and their control speed and torque conversion capability.

In cars and machines utilizing gearbox transmissions/gearboxes, the main shaft and counter shaft work together to change the gear ratio by engaging the different sets of gears.

Accurate alignment is crucial in a main shaft transmission.

Any misalignment will cause an increase in vibrations, it will accelerate the wear of the bearings, and the life of the system will be much shorter, especially if it is running at high speeds or under high loads.

Difference Between Main Shaft, Lay Shaft, and Counter Shaft

The main difference between a lay shaft and a main shaft is predominantly in their functions and to which extent they carry load.

The main shaft carries the final output torque whereas the lay shaft and main shaft combination facilitates the redirection of power through intermediate gears.

A counter shaft and a main shaft are also commonly used in a gearbox for torque transmission and space optimization.

Although these two shafts operate in a synchronized manner, the main shaft is still the load-bearing component and the power-delivering element.

Main Shaft Bearings and Supporting Components

In order to maintain load distribution as well as rotational accuracy, a main shaft bearing selection is crucial. During the functioning, bearings reduce the friction and at the same time they take up the radial and axial forces. In a heavy-duty system, an incorrectly designed bearing may cause the entire shaft assembly to fail prematurely.

Among the other components are main shaft oil seal which stops the leakage of oil thus also protects from pollution the internal parts, the main shaft speed sensor which is a device that helps to know the rotating speed and system performance in real time. To mention a few, in the commercial vehicle applications, the main shaft speed sensor DT12 is significantly helpful in transmission control and diagnostics.

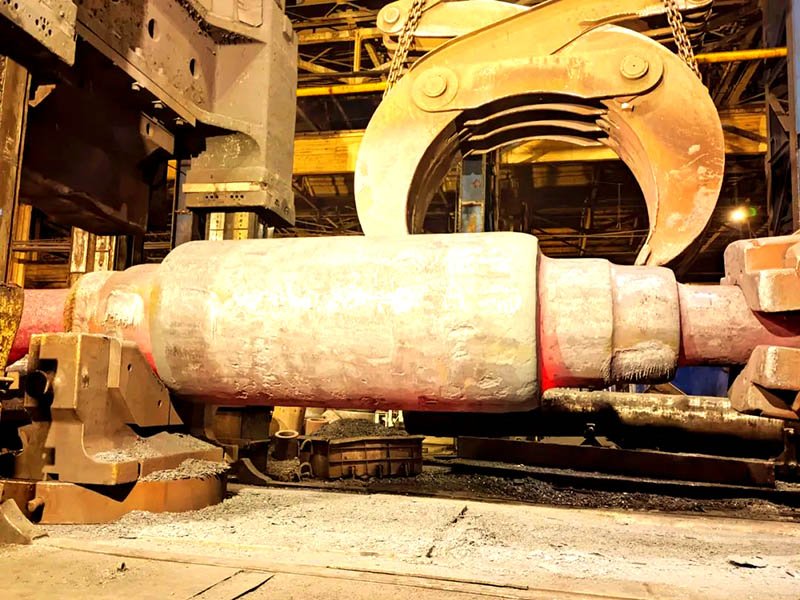

Main Shaft Applications in Wind Energy and Heavy Industry

The main drive shaft in a wind turbine is the one that brings the turning energy from the rotor to the gearbox or generator. These shafts are usually made from large diameter, high-grade materials and are structured to bear with variable loads, fatigue cycles as well as to resist even the hardest environmental conditions.

Apart from that industrial main shafts are utilized in various mining machines, rolling mills, marine propulsion systems as well as power generation equipment, where the state of being able to work non-stop with no breakdowns is the first condition of the requirement.

Automotive and Performance Main Shaft Applications

Main shafts like NV4500 main shaft, NV5600 main shaft, and T56 main shaft in the automotive sector are intended for use with high-torque manual transmissions. These shafts have to be strong, light, and accurate at the same time so that they are able to withstand demanding driving conditions and at the same time provide a smooth gear engagement.

These parts are especially vulnerable to shock loads due to being operating at high speeds and therefore, the material selection, heat treatment, and precision work have to be at a very high standard.

Main Shaft Manufacturing and Material Considerations

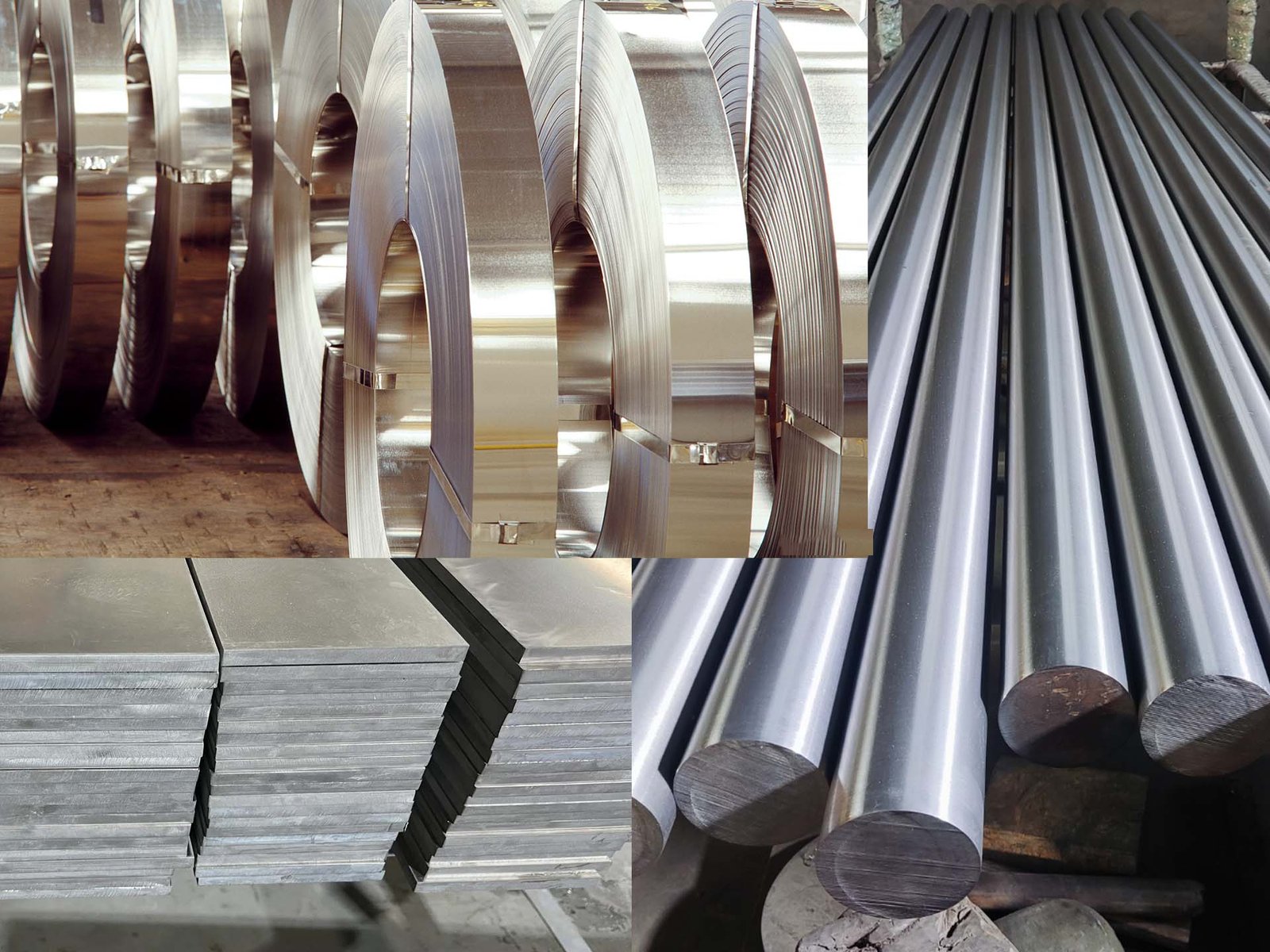

Usually, a main shaft is a product made from forged alloy steel in order to have the demanded properties such as mechanical strength and fatigue resistance. The benefits of a forgings well-aligned grain flow together with a refined internal structure make a forging much more dependable than even the best machined bar stock.

Heat treatment, rough and finish machining, turning, and grinding, are processes that after forging are carried out to comply with the requirements as to the dimensional and surface finish. In cases of an application where there are sensors, seals, or spline interfaces, the means of measurement should be very accurate.

TIP TOP Forging’s Expertise in Main Shaft Manufacturing

TIP TOP Forging is an experienced manufacturer specializing in forged main shaft components for industrial, energy, and transmission applications. Our production capabilities support customized main shaft designs based on specific load, speed, and operating environment requirements.

By combining controlled forging processes with precision machining and strict quality inspection, TIP TOP Forging delivers main shafts with consistent mechanical properties, reliable performance, and long service life. Our products are suitable for gearboxes, transmissions, wind energy systems, and other heavy-duty equipment.

Choosing the Right Main Shaft Supplier

Selecting a reliable main shaft supplier is essential for ensuring long-term equipment performance. Factors such as forging capability, material control, quality inspection, and application experience should be carefully evaluated.

Whether your project involves a gearbox main shaft, transmission main shaft, or a customized main drive shaft for industrial machinery, working with an experienced forging manufacturer like TIP TOP Forging helps reduce risk and improve overall system reliability.