TIPTOP Forging, a professional stainless steel seamless pipe manufacturer and supplier, is committed to delivering high-quality stainless steel seamless pipes for various industrial applications.

Through utilizing our in-house forging facilities, heat treatment control, and precision machining, we are able to produce seamless pipes with a combination of features such as stable mechanical properties, uniform dimensions, and good pressure resistance.

Unlike trading firms that typically sell products manufactured by others, we as a seamless steel pipe factory are directly involved in quality control from raw material forging to the final product testing. This not only helps the customers to minimize the risk of supply but also ensures long-term product reliability.

What Is a Stainless Steel Seamless Pipe and Why the Manufacturing Process Is Important

A stainless steel seamless pipe is a tube made of stainless steel and does not have any welded joints. Thus, it offers better mechanical properties such as superior strength, corrosion resistance, and the ability to withstand pressure than welded pipes.

Seamless pipes are usually the best option in case of pipe systems exposed to high-pressure, high-temperature, or aggressive media.

Being stainless-steel seamless pipe suppliers, we have knowledge that the performance of a pipe is influenced not only by the material grade but also by the manufacturing process, heat treatment, and dimensional accuracy. These are the aspects where forging-based manufacturing can deliver superior products.

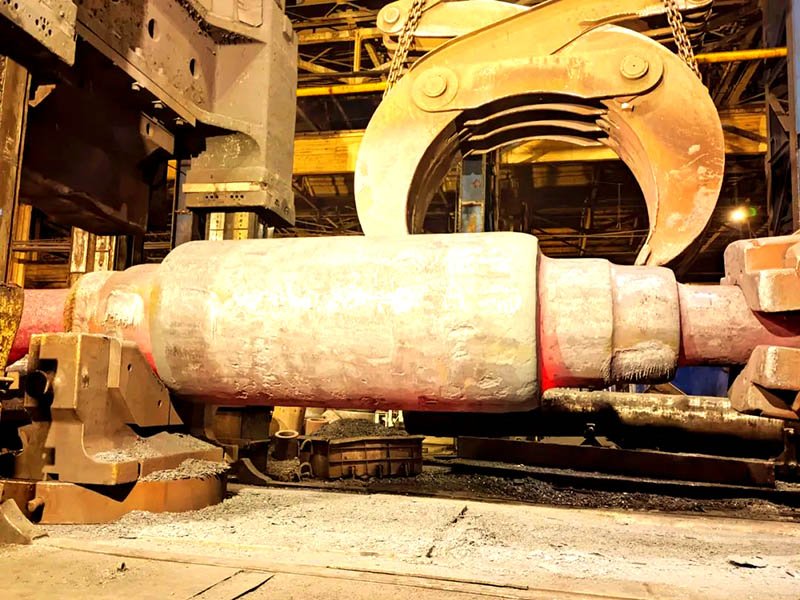

Stainless Steel Seamless Pipe Manufacturing Process in a Seamless Steel Pipe Factory

As a full-scale seamless steel pipe factory, TIP TOP Forging follows a controlled production route:

- Forged billet preparation using quality stainless steel grades

- Hot piercing and elongation to form seamless pipe hollows

- Heat treatment to achieve uniform microstructure

- Precision sizing and straightening for dimensional accuracy

- Final inspection including chemical, mechanical, and pressure testing

This integrated process allows us to operate as a reliable stainless steel seamless pipe manufacturer, especially for customers requiring consistent batch quality.

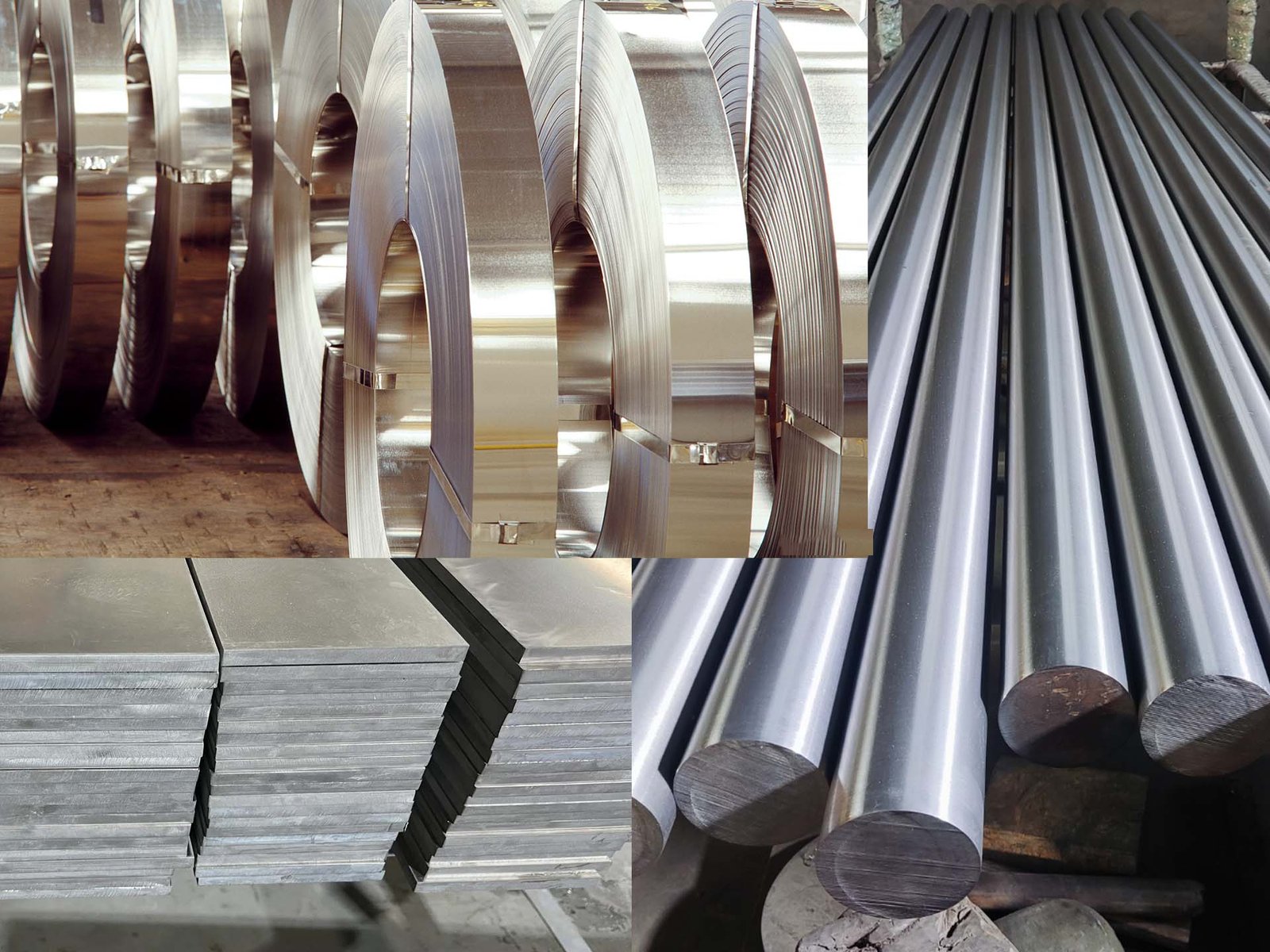

Common Grades Offered by Stainless Steel Seamless Pipe Suppliers

As one of the experienced manufacturers and suppliers of seamless stainless steel pipes, we frequently produce pipes in the commonly used grades, including:

304 Seamless Stainless Steel Pipe for General Industrial Use

304 seamless stainless steel pipe can be used for chemical processing, food equipment, heat exchangers, and generally in piping systems where corrosion resistance and forming are required.

316 Stainless Steel Seamless Pipe for Corrosive Environments

316 stainless steel seamless pipe is a type of stainless steel pipe with better resistance to chlorides and more aggressive media. Hence, it is a marine, chemical, pharmaceutical, etc., application.

Other grades can be produced based on project requirements.

Large Diameter Stainless Steel Seamless Pipe Manufacturing Capability

TIP TOP Forging is a large-diameter seamless stainless steel pipe manufacturer capable of handling the size requirements of such a product by using strict process control and equipment capability at their disposal.

Compared to the standard sizes, large diameter seamless steel pipe manufacturing requires higher deformation loads, more complex heat treatment, and tighter dimensional tolerances. Our forging-based approach enables better grain flow and structural integrity especially for the thick-wall pipes.

Stainless Steel Seamless Pipe Pressure Rating and Performance Control

One should carefully understand seamless stainless steel pipe pressure rating in order to design a safe system.

Our pipes are manufactured with attention to:

Wall thickness uniformity

Material mechanical properties

Heat treatment consistency

Hydrostatic and non-destructive testing

As experienced steel seamless pipe suppliers, we cooperate very closely with customers to achieve pressure performance that correspond to actual operating conditions.

High Productivity Stainless Steel Seamless Pipe Production for Stable Supply

Our production lines are designed to maintain a high productivity level for stainless steel seamless pipe manufacturing without compromising product quality at any stage.

Having the forging, heat treatment, and machining departments combined in one factory also helps us to cut down on the turnaround time and at the same time keeps the steady output running which is a very important factor for long-term supply contracts.

This kind of production arrangement is very useful for those customers who require trustworthy stainless steel seamless pipe suppliers rather than the ones who are only able to make spot purchases.

Quality Control System Used by Stainless Steel Seamless Pipe Manufacturer

As a responsible stainless steel seamless pipe manufacturer, quality control is embedded throughout our process:

- Raw material chemical verification

- Dimensional inspection at each stage

- Mechanical property testing

- Surface and internal defect inspection

This systematic approach ensures that pipes leaving our factory meet both standard and project-specific requirements.

Seamless Stainless Steel Pipe Price Factors Explained

Many customers ask about seamless steel pipe price. Pricing typically depends on:

- Material grade (304, 316, etc.)

- Pipe diameter and wall thickness

- Order quantity

- Testing and certification requirements

As a direct stainless steel seamless pipe supplier, we offer transparent pricing based on actual manufacturing parameters, without unnecessary trading markups.

Why Choose TIP TOP as Your Stainless Steel Seamless Pipe Supplier

Choosing the right stainless steel seamless pipe supplier is not just about price—it’s about reliability, technical understanding, and production capability.

TIP TOP Forging offers:

- Direct factory manufacturing

- Forging-based seamless pipe production

- Capability for large diameter seamless stainless steel pipes

- Stable quality and consistent delivery

This makes us a practical partner for customers seeking long-term cooperation with seamless stainless steel pipes suppliers.

Contact TIP TOP – Your Reliable Stainless Steel Seamless Pipe Manufacturer

If you are sourcing stainless steel seamless pipe for industrial, energy, or engineering applications, TIP TOP Forging is ready to support your project.

Contact us to discuss specifications, pressure requirements, and delivery schedules. Our technical team will help you select the right solution based on real operating conditions—not generic assumptions.