A carbon steel seamless pipe finds extensive usage in industrial systems that require strength, resistance to pressure, and reliability over time. In fact, seamless carbon steel pipes provide better security of the structure than welded pipes, especially in situations involving high pressure and high temperature.

TIP TOP Forging as a professional carbon steel seamless pipe manufacturer, is committed to making seamless pipes from forged billets, additionally supported by controlled heat treatment and dimensional processing. This post is a manufacturer’s viewpoint explaining our machinery, technology, specifications, and practical applications.

What Is a Carbon Steel Seamless Pipe and How It Is Produced

A carbon steel seamless pipe is a type of pipe made from solid steel billets by hot piercing and rolling processes, that is, without any welded seams. For this reason, it is possible for the pipe to have uniform mechanical properties along its entire length.

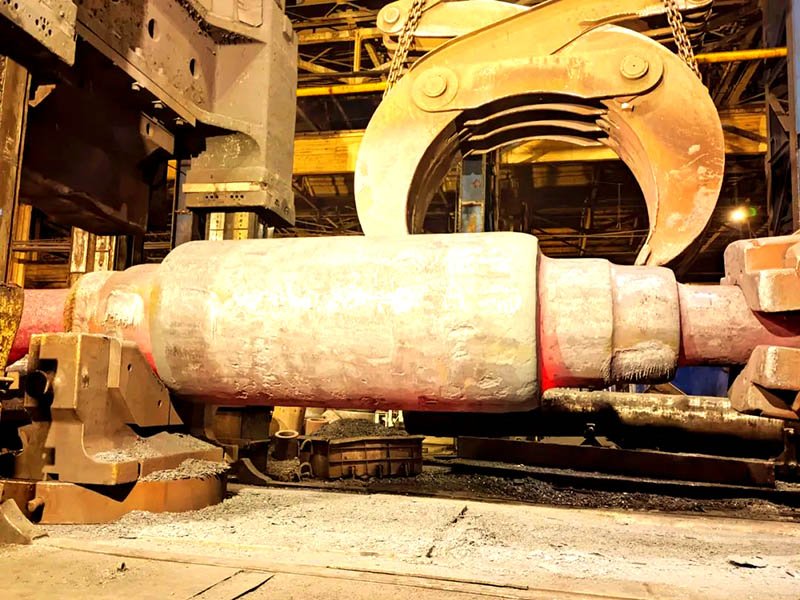

Unlike a general carbon seamless steel pipe that a trader would supply, a factory-produced seamless pipe is very much dependent on the quality of the upstream billet and the forming control. For example, at TIP TOP Forging we regard billet forging as the step that guarantees a consistent internal structure before pipe forming.

Carbon Steel Seamless Pipe Manufacturing Process in a Forging-Based Factory

As a seasoned carbon steel seamless pipe manufacturing company, TIP TOP Forging follows a production route that prioritizes the material integrity over mere speed of operation.

As one of the experienced carbon steel seamless pipe manufacturers, TIP TOP Forging operates a manufacturing route that emphasizes material integrity rather than speed alone.

The production process typically includes:

Carbon steel billet forging and conditioning

Hot piercing to form hollow shells

Seamless rolling and sizing

Heat treatment to achieve required mechanical properties

Straightening, cutting, and surface inspection

This approach allows us to function as a stable seamless carbon steel pipe supplier for industrial customers who value consistency over short-term pricing.

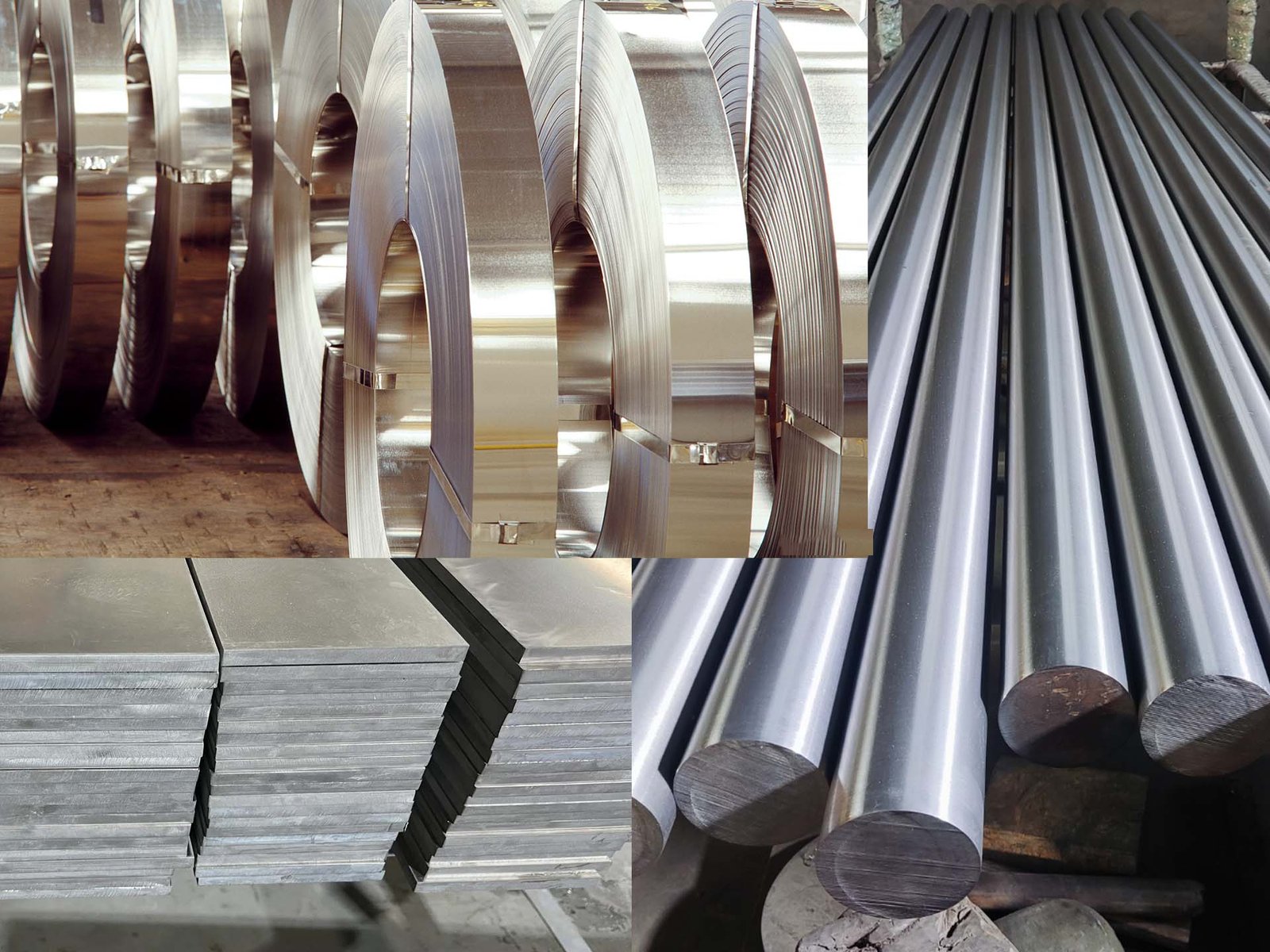

Carbon Steel Seamless Pipe Specification and Dimensional Control

Understanding carbon steel seamless pipe specification is essential for correct pipe selection. Specifications normally cover outer diameter, wall thickness, length tolerance, and mechanical properties.

As reliable carbon steel seamless pipes suppliers, we manufacture pipes according to common international standards while also supporting customized dimensional requirements for specific projects. Tight dimensional control is achieved through controlled rolling and post-processing.

Carbon Steel Seamless Steel Pipe vs Other Seamless Steel Pipes

Many customers ask about the difference between carbon steel seamless steel pipe and other seamless steel pipes.

Carbon steel seamless pipes focus on strength, weldability, and cost-efficiency, while alloy or stainless pipes emphasize corrosion or temperature resistance. For pressure systems, pipelines, and structural use, carbon steel seamless pipes remain one of the most practical choices.

Mild Steel Seamless Pipe and Carbon Steel Seamless Pipe Comparison

A mild steel seamless pipe is generally considered a low-carbon variation of carbon steel pipes. While mild steel pipes offer good ductility, standard carbon steel seamless pipes provide higher strength and broader application range.

As experienced carbon steel seamless pipe suppliers, we help customers select the appropriate carbon content based on load, pressure, and service environment rather than material name alone.

Applications of Carbon Steel Seamless Pipe in Industrial Systems

A carbon steel seamless pipe is commonly used in:

Oil and gas transmission systems

Pressure pipelines and fluid transport

Power generation and boiler systems

Mechanical structures and engineering equipment

These applications demand stable performance, which is why many buyers prefer working directly with carbon steel seamless steel pipe manufacturers rather than sourcing from mixed inventories.

Quality Control Used by Carbon Steel Seamless Pipe Manufacturers

As a factory-based carbon steel seamless pipe manufacturer, TIP TOP Forging applies quality control throughout the production process, including:

Chemical composition verification

Mechanical property testing

Dimensional inspection

Surface and internal defect examination

This systematic control ensures that each carbon steel seamless pipe delivered meets the agreed technical requirements.

How Carbon Steel Seamless Pipe Suppliers Support Project Requirements

Reliable carbon steel seamless pipes suppliers do more than deliver products. They support:

Material selection based on application

Specification confirmation before production

Stable batch consistency

Traceability from billet to finished pipe

TIP TOP Forging works closely with customers to ensure the supplied carbon steel seamless pipe fits actual operating conditions rather than theoretical assumptions.

Why Choose TIP TOP as Your Carbon Steel Seamless Pipe Supplier

Choosing the right seamless carbon steel pipe supplier directly affects project safety and lifecycle cost.

TIP TOP Forging offers:

Forging-based billet preparation

In-house seamless pipe manufacturing control

Stable supply for standard and customized pipes

Technical support from production-oriented engineers

These advantages make us a practical partner among carbon steel seamless pipe suppliers serving long-term industrial projects.

Contact TIP TOP Forging for Carbon Steel Seamless Pipe Solutions

If you are sourcing carbon steel seamless pipe for industrial, energy, or engineering applications, TIP TOP Forging can support your requirements with reliable manufacturing and realistic technical guidance.

Contact our team to discuss specifications, production capability, and delivery planning. We focus on providing workable solutions rather than over-promised claims.