ABOUT US

Who we are

TIPTOP Forging

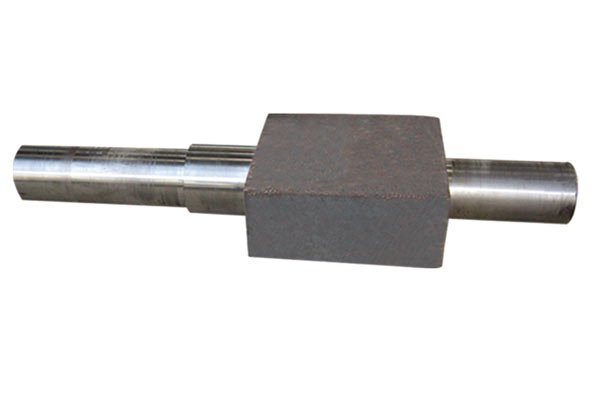

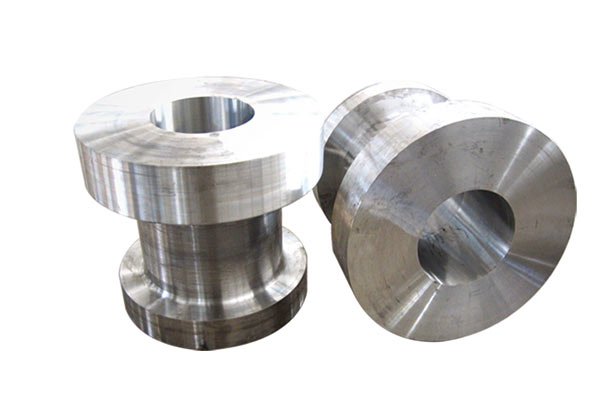

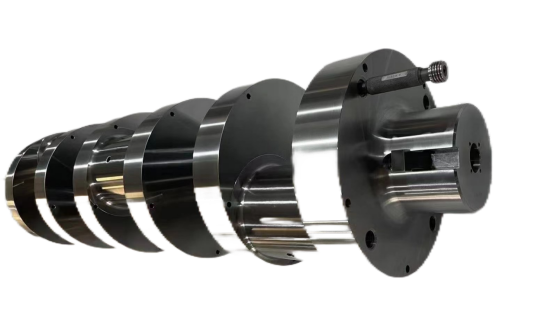

TIPTOP Forging stands as a modern high-tech enterprise, possessing robust technical prowess, comprehensive production equipment, and stringent testing facilities. It is principally engaged in the R&D, production, sales, and service of a diverse range of large and medium-sized forgings. These forgings are crafted from various materials including Carbon steel, alloy steel, stainless steel, nickel-based alloy steel, copper alloy, aluminum alloy, titanium alloy,etc. and cover products such as shafts, metallurgical rollers, pipe molds, round bars, hollow bars, steel blocks, turbine shafts, 4145H mod stabilizer forgings, non-magnetic drill collar forgings, and irregular forgings.Our supplied shaft forgings size of lengths up to 25 meters and unit weights up to 200 tons,the diameter is determined by the maximum unit weight and length. Such products find extensive application across various fields such as Petroleum, power generation, chemical, shipbuilding, metallurgy, machinery, military, and aerospace.

TIPTOP can manufacture forgings of various materials and shapes

Our Value

Top Quality and Reputation are Fundamentality of Survival.

Production Facilities

Working Ability

Reputation certification

Our ISO certificate

As an ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 certified forging manufacturer, we embody global standards for quality precision, sustainable operations and workplace safety.

Materials for forging parts

As a professional forging company, our forging materials have high strength, extreme environment resistance and long life as their core advantages. We use high-performance alloy formulas (such as titanium alloys, nickel-based high-temperature alloys, etc.), combined with precision controlled forging technology and multi-stage heat treatment technology to ensure that the materials have excellent fatigue resistance, high temperature resistance and corrosion resistance. They can meet the ultra-harsh working conditions in aerospace engine parts, deep-sea equipment pressure structures, new energy heavy machinery and other fields. At the same time, we provide material composition customization and full-process quality traceability services to help customers achieve the comprehensive goals of lightweight, high reliability and cost optimization.

Carbon steel

Carbon steel is an iron-carbon alloy with a carbon content of less than 2.11% and is the most common type of steel.

Alloy steel

Alloy steel is made by adding one or more alloying elements to carbon steel to improve its properties.

Stainless steel

Stainless steel is a kind of alloy steel, which is widely used in many fields.

Copper alloy

Copper alloy is an alloy composed of copper as a matrix, adding one or more other elements (such as zinc, tin, nickel, aluminum, etc.).。

Aluminium alloy

Aluminum alloy is a general term for aluminum matrix alloys, containing copper, magnesium, silicon, manganese, zinc and other alloying elements.

Nickel alloy

Lorem ipsum dolor sit amet elit ut elit tellus luctus nec ullamcorper mattis pulvinar dapibus leo..

Introduction

How we became best among others?

Since its establishment, the company has always adhered to the purpose of “quality first, reputation is the basis of survival”, adhered to the business philosophy of “quality first, honest service”, and established an impeccable quality assurance system in strict accordance with iso9001-2008 standards to provide customers with satisfactory products and after-sales service.

“We built Beautifully with the best possible materials and resources”

- Quality Control System, 100% Satisfaction Guarantee

- Highly Professional Staff, Accurate Testing Processes

- Unrivalled workmanship, Professional and Qualified

Our mission

With precision forging technology as the core, we provide customers with zero-defect and high-performance forging solutions to help cutting-edge industrial equipment break the limit

Our vision

To become the global innovation leader in the field of high-end forging parts, to promote the upgrading of industrial equipment with excellent quality and continuous innovation, and to achieve an efficient, reliable and sustainable manufacturing future together with customers

Our value

High performance material customization : For extreme environments (high temperature, high pressure, corrosion, etc.), we provide customized forging solutions for nickel-based alloys (Inconel series), titanium alloys, special steels and other materials to meet the demanding needs of aerospace, energy, petrochemical and other industries

CONTACT US

Let's Get in

Touch

Email Address

sales@tiptopforging.com

Call Us

Phone : +86 0538 6368027

Address

Taishan Street,Taian City,ShanDong, China