Alloy seamless steel pipes are extensively used in industrial settings of high temperature, high pressure, and chemical corrosion. The structural integrity and mechanical performance of alloy seamless steel pipes are superior to that of welded pipes, ascribed to the absence of welding in the manufacturing process of seamless pipes.

The paper provides an overview of the materials, grades, sizes, uses, and manufacturing methods of alloy seamless steel pipe products and gives a brief account of TIP TOP Forging as a dependable seamless steel pipes company in China.

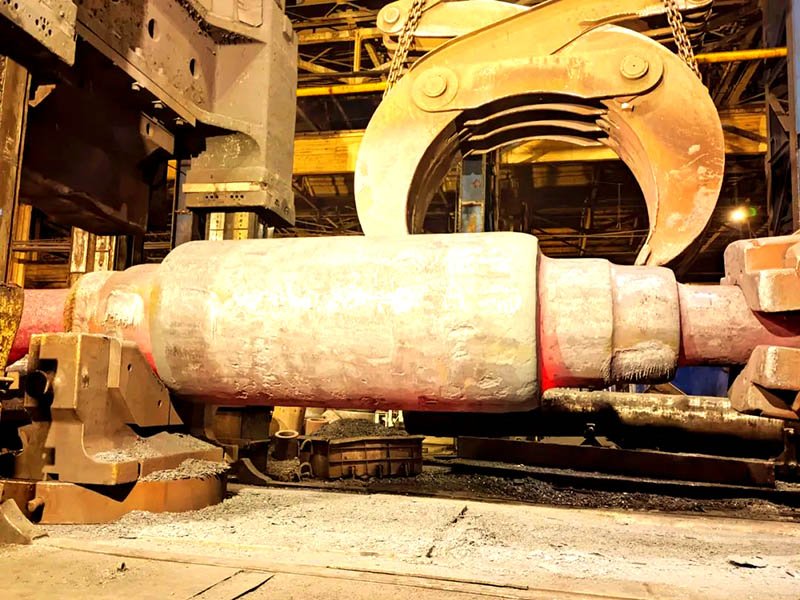

Alloy Seamless Steel Pipe Manufacturing Process and Production Technology

The performance of an alloy seamless steel pipe begins with its production method. Seamless pipes are typically manufactured through:

- Hot rolling process

- Cold drawing or cold rolling process

- Heat treatment for mechanical property control

- Straightening and precision finishing

Unlike alloy welded pipes, an alloy seamless steel pipe does not have a welded seam, which contributes to an increase in pressure resistance and structural reliability.

TIP TOP Forging manufacture alloy steel seamless pipes under stringent temperature and deformation control conditions to guarantee a homogeneous grain structure and uniform mechanical properties.

Alloy Seamless Steel Pipe Materials and Seamless Ferritic Alloy Steel Pipe Grades

Material selection plays a major role in determining the performance of an alloy seamless steel pipe. The following are the most commonly used grades:

- ASTM A335 P11

- Alloy steel P12 seamless pipes

- P22, P91 and other chromium-molybdenum steels

Seamless ferritic alloy steel pipe grades for high-temperature service

These materials find extensive applications in:

- Power generation boilers

- Petrochemical plants

- Oil and gas pipelines

- Heat exchangers

A seamless ferritic alloy steel pipe is the right choice when it comes to high-temperature environments requiring creep resistance.

Alloy Seamless Steel Pipe Dimensions and Standard Specifications

Precise seamless steel pipe dimensions are necessary for safe fitting and effective working over the pipe service life.

Alloy seamless steel pipe dimensions generally refer to:

- Outside diameter (OD)

- Wall thickness (WT)

- Length (fixed or random length)

- Weight per meter

Most of the time, the standards that are followed belong to ASTM, ASME, DIN, EN, and GB.

Being a seamless steel pipes manufacturer, TIP TOP offers dimensional verification and certification services to ensure that the products are according to the requirements of the customer.

Alloy Seamless Steel Pipe Applications in Oil, Gas, and Power Industries

Typically, an alloy seamless steel pipe is the correct answer for:

- High-pressure steam pipelines

- Refinery processing lines

- Chemical transportation systems

- Boiler tubing

- Offshore and onshore oilfield facilities

In power plants, alloy steel seamless pipes like P12 and P22 are the most common components in superheated steam lines because of their great ability to resist oxidation and high temperature deformation.

Alloy Seamless Steel Pipe vs Welded Pipe: Performance Comparison

When an alloy seamless steel pipe is compared with a welded pipe,

Here are several of the benefits of using an alloy seamless steel pipe:

- There is absence of welding seam

- Possesses a higher capacity for pressure

- Has better fatigue strength

- Has better performance in cyclic loading environments

Nevertheless,costs of welded pipes may be cheaper for low-pressure purposes. Selection is based on operation conditions and design necessities.

Alloy Seamless Steel Pipe Quality Control and Inspection

Products of reliable alloy seamless steel pipe can only come from a strict quality control program that includes chemically verifying the material and mechanically testing the property of the material.

- Chemical analysis

- Mechanical testing

- Ultrasonic testing (UT)

- Hydrostatic pressure testing

- Dimensional verification

TIP TOP as a professional seamless steel pipes company ensures that every batch of alloy steel seamless pipe is inspected according to the applicable standards before shipment.

Alloy Seamless Steel Pipe Supply from Seamless Steel Pipe China Manufacturer

China is still a major production base for alloy seamless steel pipe products. Meanwhile, buyers should assess a supplier based on production capacity, quality control system, export experience, documentation support, and a stable delivery schedule.

TIP TOP Forging as a seamless steel pipe China manufacturer is a reliable partner if you are looking for a supplier of alloy steel seamless pipe in the energy and heavy industry sectors.

Alloy Seamless Steel Pipe for Sale: What Quality Seamless Steel Pipe Distributors Look For

Generally, customers will be concerned about grade authenticity, traceability documentation, consistent wall thickness tolerance, surface finish, and packaging for international shipping when they are looking for quality distributors of seamless steel pipe or sourcing alloy steel seamless pipes.

TIP TOP supports customers who require bulk orders or long-term cooperation agreements both as a manufacturer and a supplier.

Alloy Seamless Steel Pipe Production Capability at TIP TOP Forging

- Alloy steel seamless pipe production

- P12 and other Cr-Mo grade pipes

- Custom seamless steel pipe dimensions

- Heat treatment and finishing services

- Export-ready packaging

We do not claim to be the largest supplier, but we focus on:

- Stable production control

- Reliable material sourcing

- Transparent technical communication

- Consistent product quality

Our goal is to supply alloy seamless steel pipe solutions suitable for high-pressure and high-temperature industrial systems.

Contact TIP TOP Forging for Alloy Seamless Steel Pipe Supply

If you are sourcing alloy seamless steel pipe, alloy steel seamless pipes, or alloy steel P12 seamless pipes for industrial projects, TIP TOP Forging can provide technical data and production support.

Contact our team to discuss:

- Required grade and specifications

- Seamless steel pipe dimensions

- Quantity and delivery timeline

- Export documentation

We aim to provide reliable alloy seamless steel pipe solutions for power, oil, gas, and heavy industry applications.