BLOG

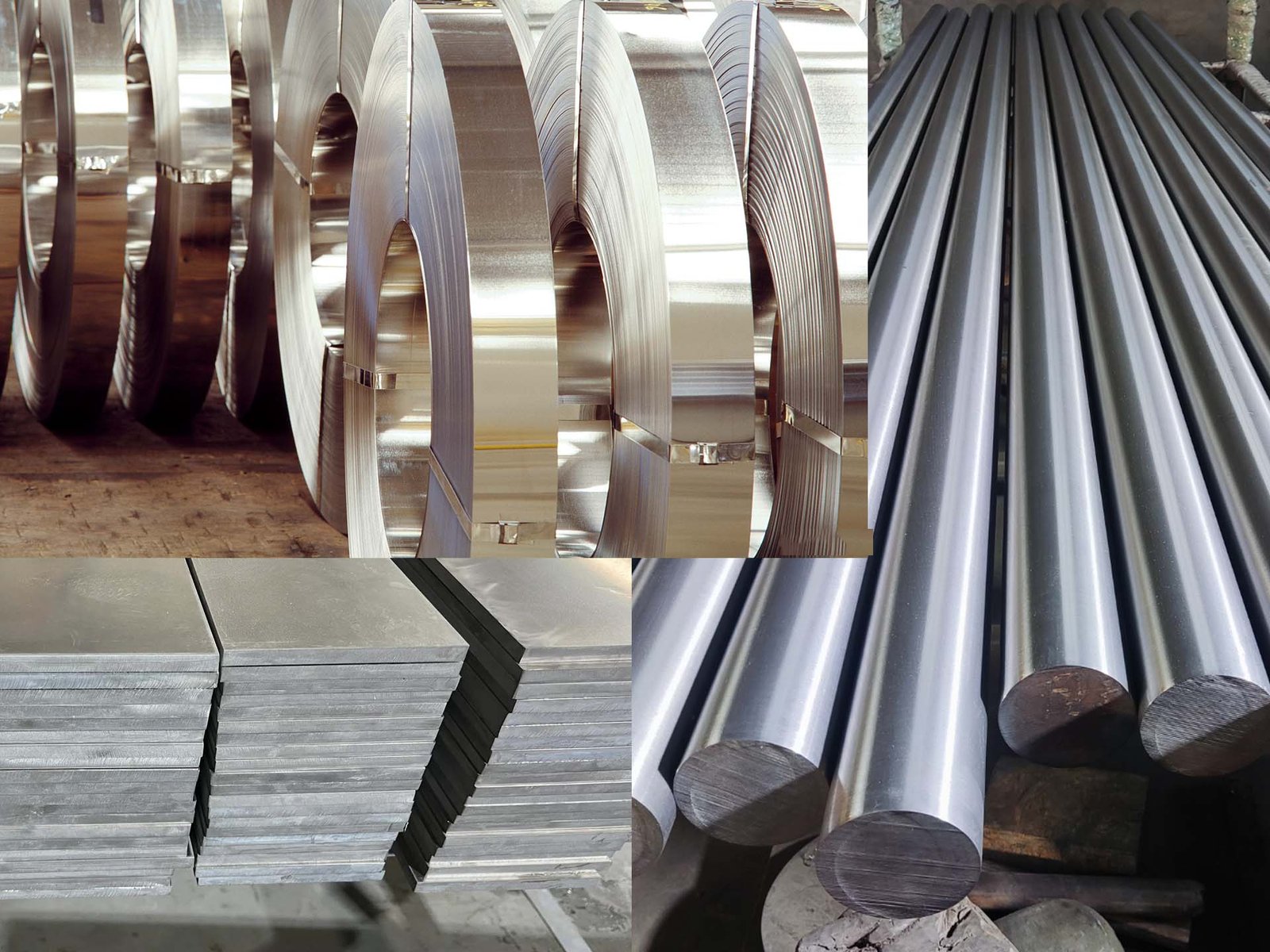

Titanium alloys are the first materials that come to mind when talking about an outstanding strength-to-weight ratio, corrosion resistance, and high-temperature performance. As the use of these materials keeps expanding in the aerospace, oil & gas, marine, and chemical industries, it is becoming more and more essential that buyers and engineers comprehend titanium alloy materials, their composition, forms, and the processes by which they are made.

In modern industrial manufacturing, standardized components often fail to meet the demands of high-performance and specialized applications. As a premier custom forged parts manufacturer, TIP TOP Forging is dedicated to providing superior custom forging solutions. We understand that every project is unique, which is why we focus on delivering higher strength, longer service life, and components that meet your exact specifications through advanced custom metal forging. Whether you require custom steel forging or high-grade custom aluminum forgings, TIP TOP is your trusted partner for excellence.

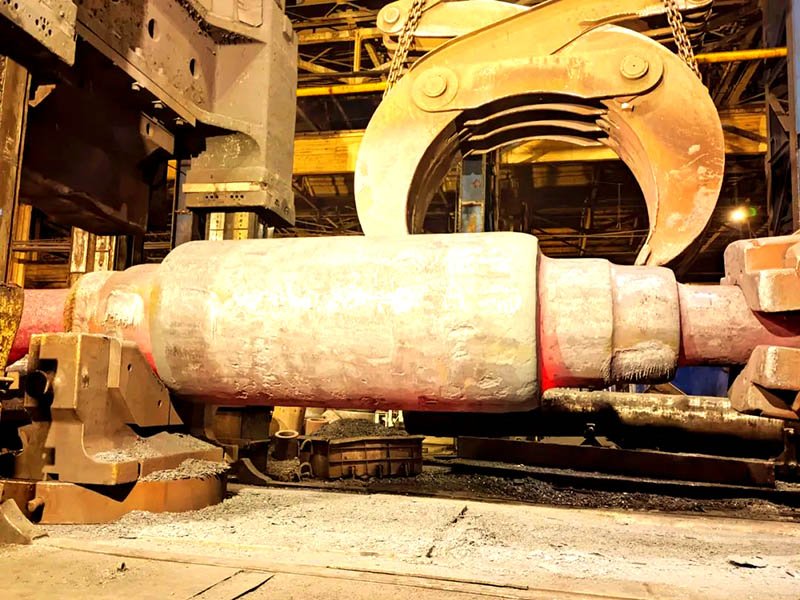

The marine crankshaft is the central rotating shaft in a marine engine that converts the reciprocating motion of pistons into rotational motion. In simple terms, the crankshaft meaning in marine applications is a critical structural component that enables a ship’s main engine to generate propulsion power efficiently.

A billet crankshaft is a high-performance crankshaft machined from a solid metal block known as a Billet. Unlike cast or forged crankshafts, billet crankshafts are crafted from premium solid steel or alloy blocks with precise machining that results in superior material integrity, balanced weight distribution, and enhanced strength. Because of these properties, crankshaft billet products are widely used in high-load applications such as performance engines, racing vehicles, marine drives, and industrial machinery.

Oil and gas forgings are metal parts that have been specifically created for being used in oilfield drilling, production, pipeline, and petrochemical systems. In comparison to cast or welded components, forgings in the field of oil and gas give a better grainy structure, more mechanical strength, and a better capability in fighting the pressures, impacts, and fatigue.

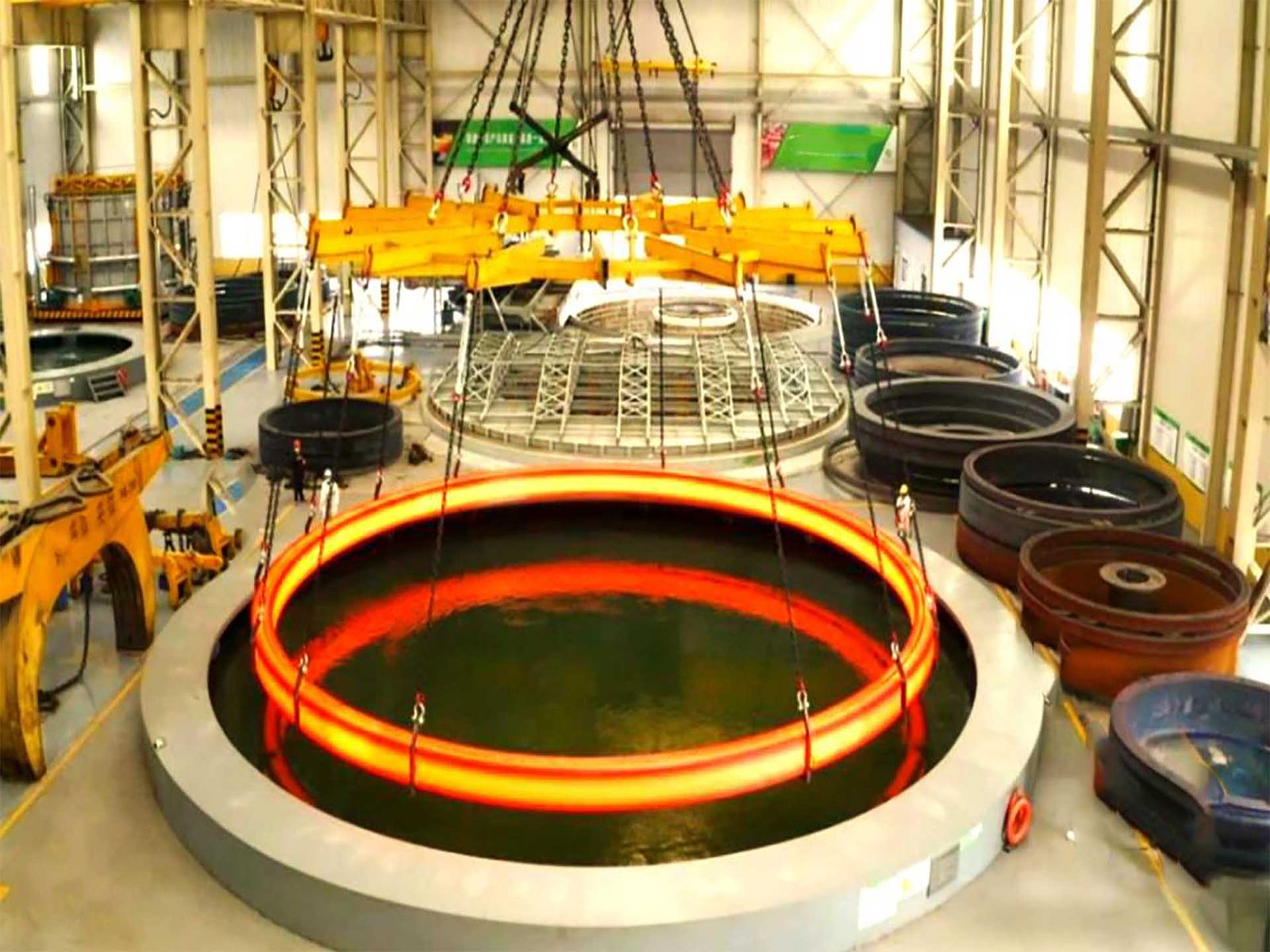

What Is a Forging Ring and Why It Matters in Modern Industries

A forging ring—often referred to as a forging ring component, ring of forging, forged ring, or ring forging—is a circular metal product shaped through high-pressure deformation processes. Compared with casting or fabrication, forging ring manufacturing delivers superior strength, uniform grain flow, and excellent performance under high loads and extreme conditions.

Cold forging is one of the metal forming methods, which deals with the shaping of materials at room temperature. Instead of raising the temperature as in hot forging, the process of cold forging uses extremely high-pressure to plastically change the structure of metal, such as steel, aluminum, or other alloys to the specified shape. This method contributes to the achievement of near to perfect dimensional accuracy, smooth texture, and mechanical properties enhancement, which is the reason why it is a very popular technique in the production of fasteners, automotive parts, industrial equipment, and aerospace components.

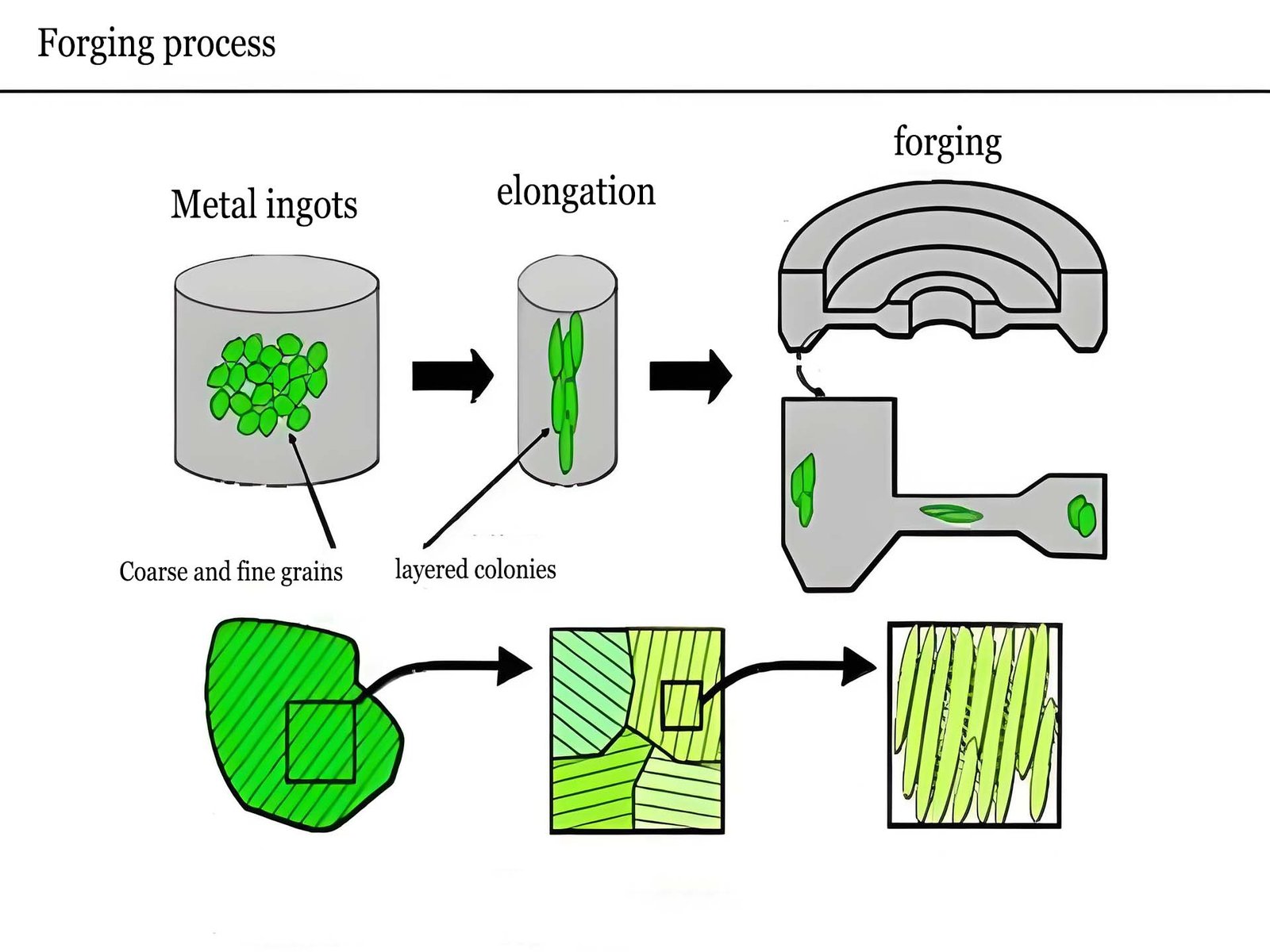

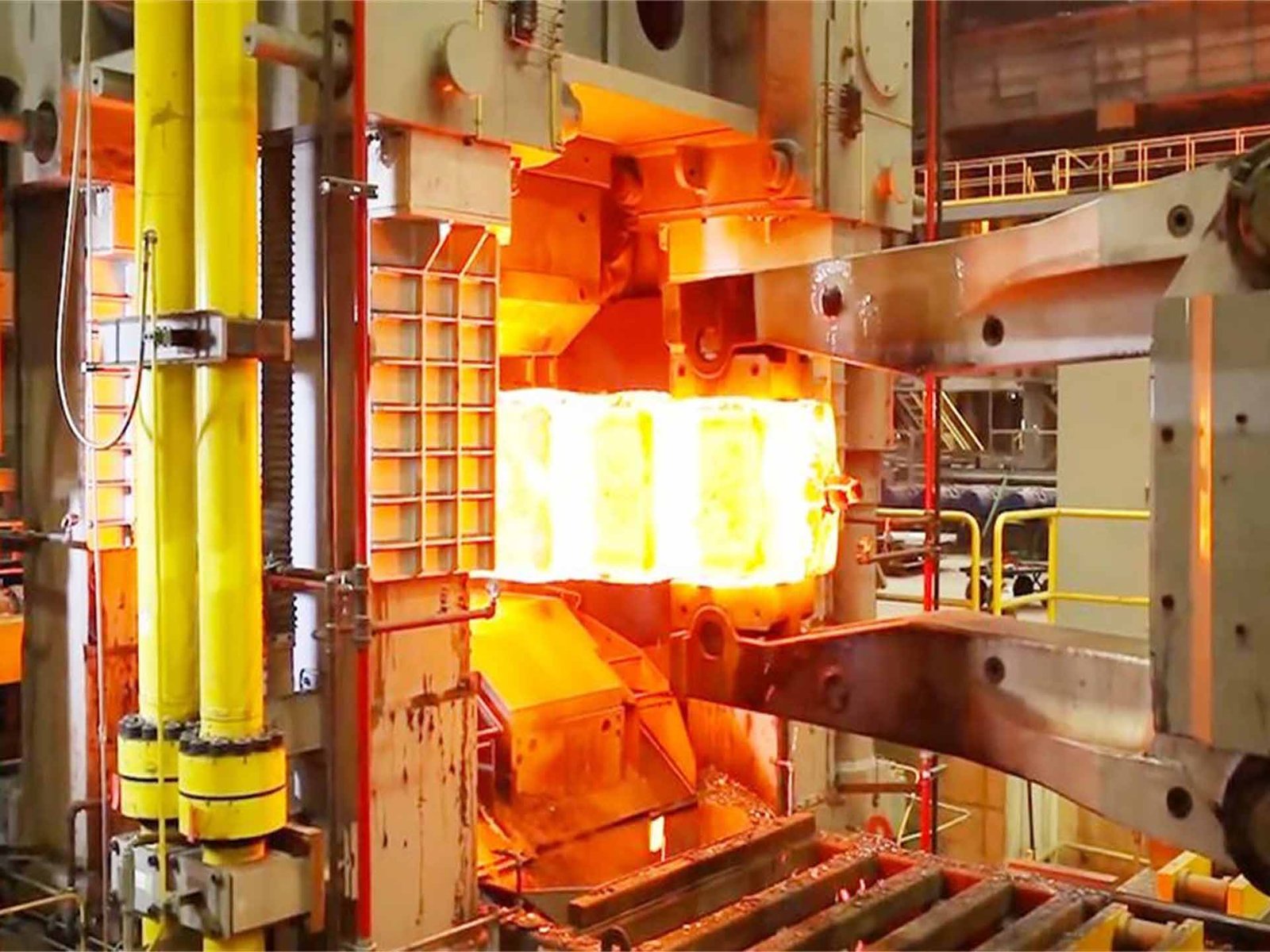

Forging is the process of metal forming which involves the use of extreme compressive force to reshape heated materials to make strong and durable components. In contrast to casting, which requires melting metal, in a forging process metals are shaped by hammering, pressing, or rolling in a controlled manner. The outcome is a dense, uniform grain structure that offers high mechanical strength, fatigue resistance, and reliability.