BLOG

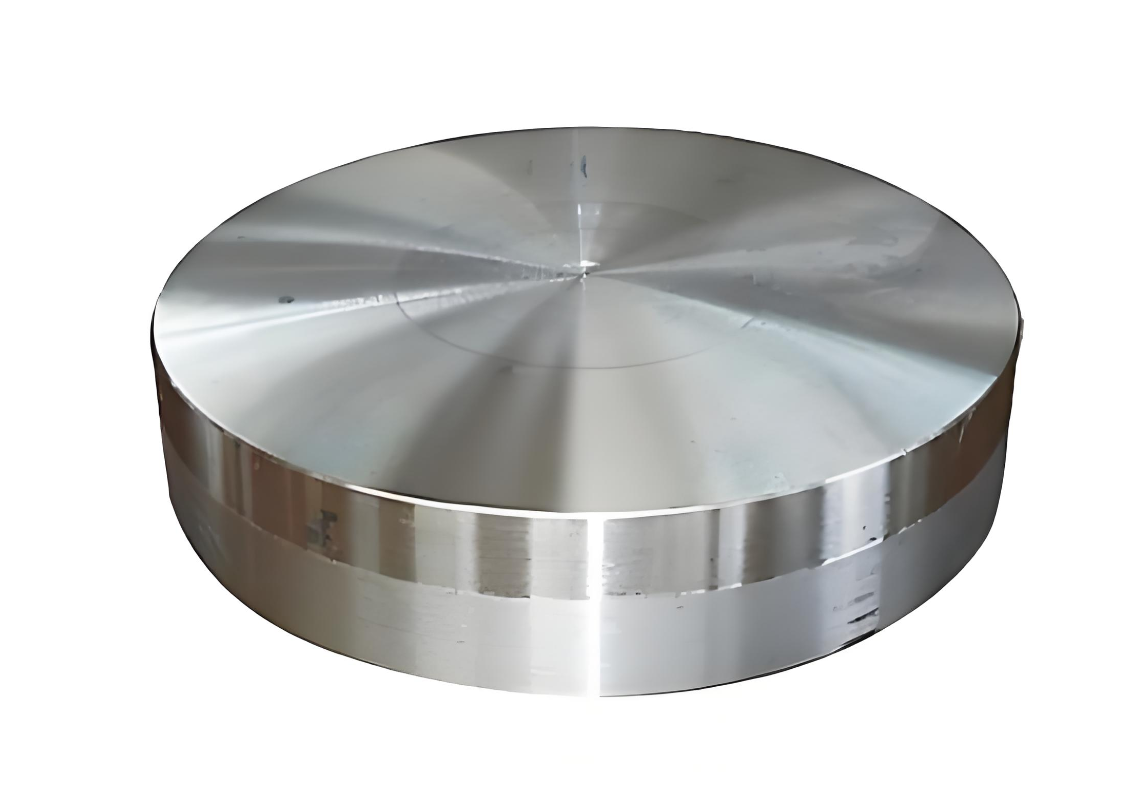

In today’s high-performance industries — from oil & fuel to electricity generation, marine, and heavy tools — customized solid metal disks are relied on for one reason: they don’t fail. When widespread components fall short, solid disks custom-made to your specs supply unmatched strength, reliability, and lifecycle value.

Open Die Forging is a manufacturing procedure the place steel is fashioned between flat or barely contoured dies that do no longer absolutely enclose the material. This approves the steel to go with the flow and be fashioned into preferred shapes. Unlike Closed Die Forging, the place the cloth is constrained inside a die cavity, Open Die Forging offers increased freedom to shape larger, custom-shaped components — therefore its different name, Free Forging.