What is Cold Forging?

Cold forging is a steel forming technique the place metallic is formed at or close to room temperature the use of excessive pressure. Unlike warm forging, bloodless forging does now not contain heating the fabric earlier than deformation, which makes it perfect for accomplishing excessive dimensional accuracy and incredible floor finish.

Cold Forging vs. Hot Forging

Cold Forging: Done at room temperature. Results in improved strength due to work hardening.

Hot Forging: Done at elevated temperatures. Allows greater material flexibility but lower precision.

Cold forging is often used when tight tolerances and surface finish are critical.

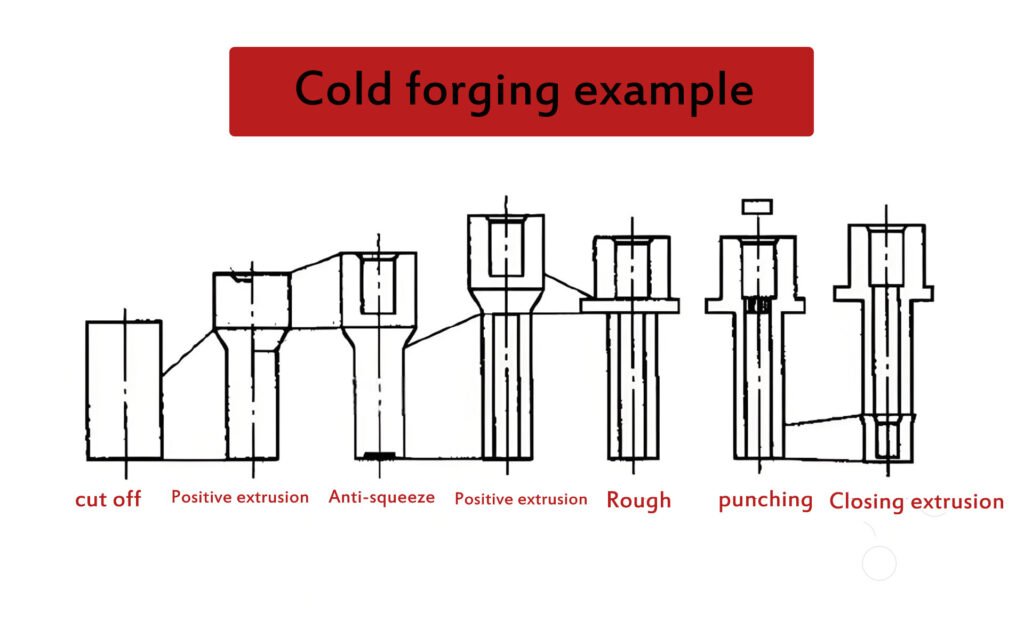

How the Cold Forging Process Works

Step 1: Material Selection & Preparation

Choosing the right material is crucial. The material is typically cleaned, cut into slugs, and inspected for surface defects.

Step 2: Lubrication and Die Setup

Lubricants like zinc phosphate coatings or oil-based films are applied to reduce friction and protect dies. Dies are carefully aligned and precision-ground.

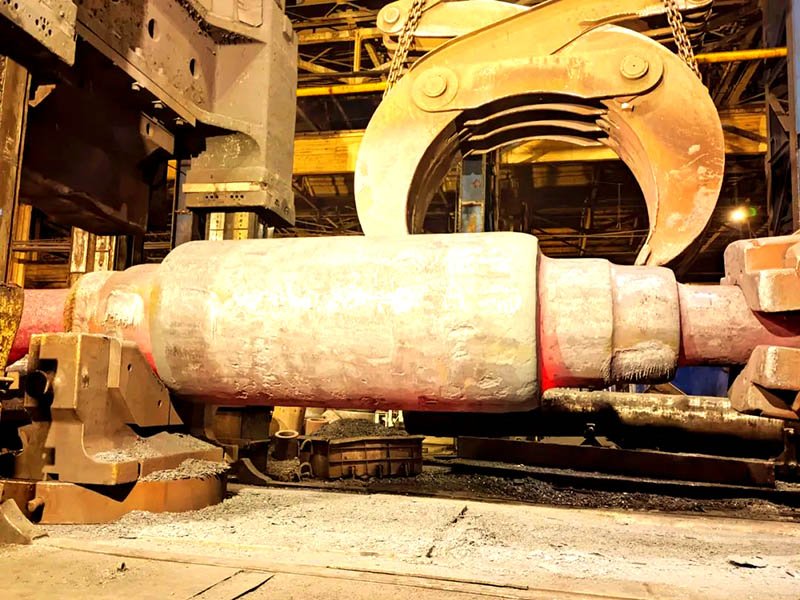

Step 3: Deformation at Room Temperature

A high-tonnage press applies extreme pressure to deform the metal slug into the desired shape — all without heating. The process may involve extrusion, upsetting, or coining.

Step 4: Final Shaping & Precision Finishing

Secondary operations like trimming, piercing, or polishing are used to achieve exact tolerances and surface finishes.

Common Equipment Used in Cold Forging

Mechanical presses

Hydraulic presses

High-speed forging machines

Automated feeding systems

Benefits of Cold Forging

Superior Surface Finish and Dimensional Accuracy

Cold forging eliminates scale formation and delivers smoother surfaces — often without needing additional machining.

Increased Mechanical Strength

Work hardening during deformation enhances hardness, fatigue resistance, and tensile strength.

Material Efficiency & Cost Reduction

Minimal waste is generated; near-net shaping reduces the need for excess stock and machining.

Higher Production Speeds

Cold forging is ideal for mass production — faster cycle times and high repeatability.

Sustainability & Environmental Impact

No heating means lower energy consumption

Fewer emissions

Less material waste

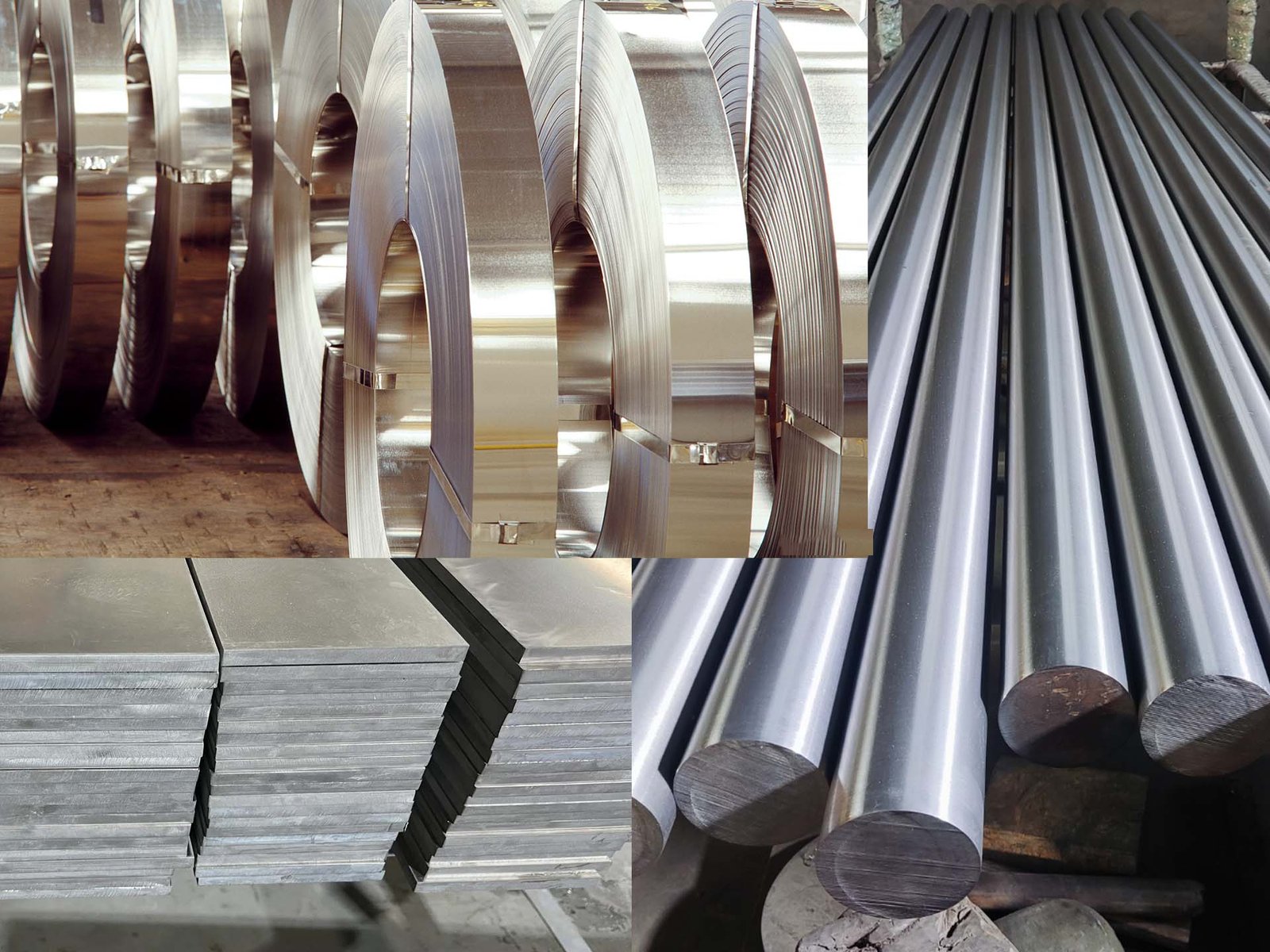

Materials Commonly Used in Cold Forging

Popular Cold Forging Metals

Carbon steel (e.g., AISI 1010, 1045)

Alloy steel (e.g., 4140, 8620)

Aluminum and aluminum alloys

Copper and brass

Why These Materials Work Best

These metals exhibit good ductility and formability at room temperature, making them ideal for cold deformation.

Material Selection Tips

Consider hardness and yield strength

Evaluate formability at room temperature

Match material to product function and industry standards

Applications of Cold Forging in Modern Industries

Automotive Components

Bolts, nuts, shafts, gears

High-volume production with tight tolerances

Aerospace Fasteners and Connectors

Rivets, pins, bushings

Requires strong, lightweight, and fatigue-resistant parts

Electronics, Tools, and Medical Devices

Precision connectors, surgical tools, small housings

Cold Forging Challenges and Solutions

Die Wear & Maintenance

Solution: Use of advanced die materials and coatings; regular inspection and regrinding schedules.

Limitations with Complex Shapes

Solution: Combine cold forging with secondary processes like machining or hot forging preforms.

Work Hardening Issues

Solution: Use intermediate annealing if necessary; select materials that balance strength and ductility.

Post-Forging Requirements

Heat treatments (if needed for specific mechanical properties)

Surface finishing (coating, plating)

Summary & Key Takeaways

Cold Forging Process at a Glance

A cost-effective, high-precision forming technique

Enhances mechanical properties

Suitable for medium-to-high production volumes

Is Cold Forging Right for Your Application?

Evaluate:

Required tolerances

Mechanical strength needs

Production scale

Material compatibility

Need help deciding? Our team can guide you through material selection and process design.

FAQs: Cold Forging

What temperature is cold forging performed at?

Typically at room temperature, usually below 100°C. True “cold forging” avoids heating beyond material softening thresholds.

Can stainless steel be cold forged?

Yes. Austenitic stainless steels (e.g., 304, 316) can be cold forged, though higher pressures are required.

How does cold forging save production costs?

Less material waste

Fewer machining steps

Faster production cycles

Is post-forging heat treatment required?

Sometimes. It depends on desired mechanical properties — cold forging induces work hardening that may need stress relief or tempering.