Custom forging services provide engineered metal components designed to meet exact performance, dimensional, and application requirements. Compared with standard off-the-shelf forgings, custom forgings offer superior mechanical integrity, optimized grain flow, and greater design flexibility for demanding industries such as oil & gas, aerospace, power generation, and heavy equipment manufacturing.

At TIP TOP Forging, we deliver end-to-end custom forging services—from material selection and process design to forging, heat treatment, and final machining—ensuring every forged part meets its intended service conditions.

Custom Forging Services Overview and Manufacturing Capabilities

Professional custom forging services involve shaping heated metal using controlled compressive forces to achieve near-net or fully engineered geometries. Depending on part size, complexity, and mechanical requirements, forging methods may include:

Open-die forging

Closed-die forging

Ring rolling

Custom metal hammer forging

Custom hammer forging is especially effective for large-section components requiring enhanced fatigue resistance and directional strength.

Custom Forging Services and Custom Forgings Materials Selection

Selecting the right custom forgings materials is the foundation of performance. TIP TOP Forging supplies and forges a wide range of metals, including:

Custom carbon steel forgings for structural and pressure-bearing parts

Custom alloy steel forgings for high-strength and fatigue-critical applications

Custom chrome moly forgings for elevated temperature and pressure environments

Material grades are selected based on load, temperature, corrosion exposure, and service life requirements.

Custom Forging Services for Alloy, Stainless, and Specialty Steel Bars

Bar-shaped forgings are widely required across industrial sectors. Our custom forging services include:

4130 custom forged bars for oilfield and mechanical applications

317 SS custom forged bars for corrosive and chemical environments

Oil & gas custom steel bar forgings for drilling, completion, and production equipment

Forged bars offer superior internal soundness and mechanical uniformity compared to rolled products.

Oil & Gas Custom Forging Services for Bars and Rolled Forgings

For upstream energy applications, custom forging services must meet high pressure, impact, and fatigue demands. TIP TOP Forging provides:

Oil & gas custom steel bar forgings

Oil & gas custom steel rolled forgings

These components are used in wellhead equipment, pressure control systems, subsea tooling, and surface facilities where reliability is critical.

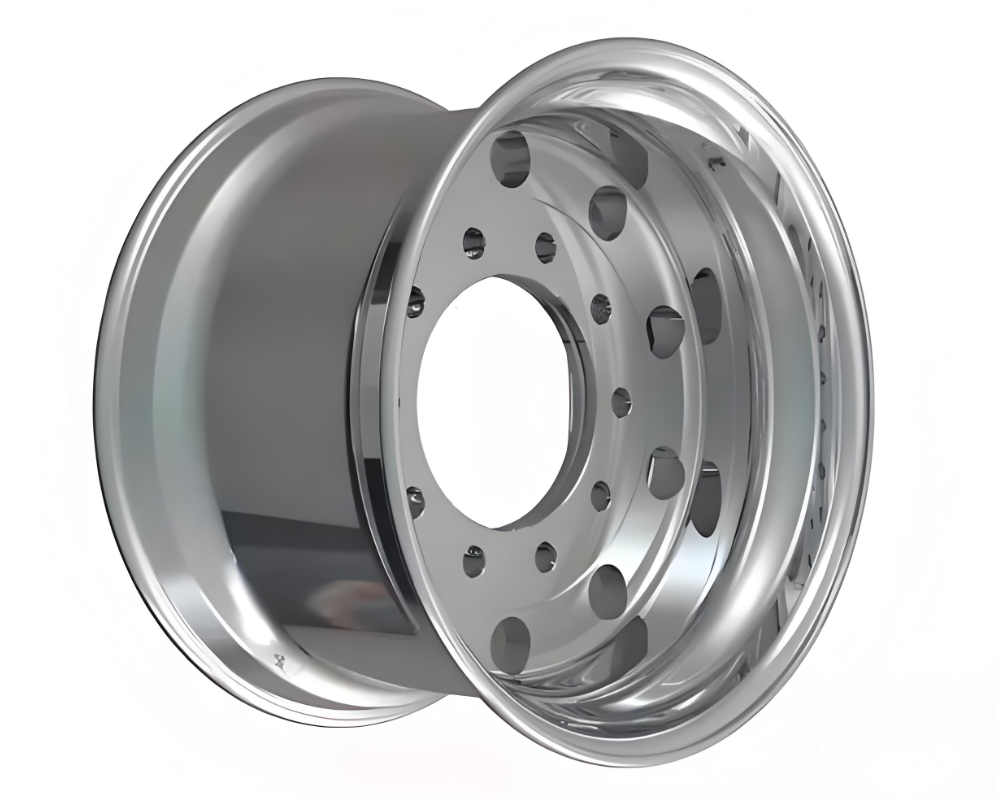

Custom Forging Services for Wheels, Rims, and Rotating Components

Beyond industrial equipment, custom forging services are also used in rotating and load-bearing assemblies. We manufacture:

Custom forged wheels and forged custom wheels

Custom made forged wheels for heavy-duty and specialty applications

Custom forged rims requiring high impact resistance and structural balance

Forging improves grain alignment, reducing the risk of cracking under cyclic loading.

Custom Forging Services Using Hammer Forged and Near-Net Shapes

Custom hammer forged parts and custom metal hammer forging processes allow precise control over deformation paths. This approach:

Enhances directional strength

Reduces internal defects

Minimizes machining allowance

Near-net forged shapes also help customers reduce material waste and machining costs.

Superalloy and Nickel-Based Custom Forging Services

For extreme service conditions, TIP TOP Forging provides custom forging services using:

Nickel-based superalloys

Heat-resistant and corrosion-resistant alloys

These superalloy custom forged parts are commonly used in aerospace, power generation, chemical processing, and high-temperature industrial systems.

Quality Control in Custom Forging Services

Reliable custom forging services require strict quality management throughout the process, including:

Chemical composition verification

Controlled forging ratios

Heat treatment optimization

Dimensional and non-destructive inspection

Forged components are manufactured to ensure consistency, traceability, and long-term service reliability.

TIP TOP Forging: Professional Custom Forging Services Manufacturer

TIP TOP Forging is a dedicated manufacturer providing global customers with engineered custom forging services. Our capabilities include:

OEM carbon, alloy, stainless, and nickel alloy forgings

Large-section open-die forgings and rolled rings

OEM forged bars, wheels, rims, and specialty components

Thanks to our in-house forging skills and versatile production capacity, we are able to deliver a wide range of products, from small-batch custom projects to large-volume industrial programs.

Benefits of Forged Components

Forged components have the following advantages over casting or machining from the plate:

Have a higher fatigue and impact resistance

Have a better structural integrity

Get longer service life under cyclic stress

This is why forged solutions are still the primary option for safety-critical and high-load applications.

Summary: Custom Forging Services Adapted to Your Application

Quality custom forging services are a perfect combination of material science, process control, and manufacturing knowledge. Whether it be custom alloy steel forgings and nickel alloy forgings or custom forged wheels and oil & gas components, well-designed forgings guarantee the highest level of performance and reliability.

TIP TOP Forging is the reliable partner for your custom forging services. We will be pleased to provide you with technical expertise and manufacturing precision.

Get in touch with TIP TOP Forging regarding Custom Forging Services

You are welcome to send us your drawings, specifications, or application requirements. Our engineers will identify the most suitable materials, forging methods, and solutions that will fit both your needs and budget.