Power Generation

With the development of the energy and electronics industries, the demand for forgings continues to increase. Especially in the field of renewable energy, such as wind power generation and nuclear power generation, the application of forgings will be further expanded.

Reliable Power Generation Components for Energy Efficiency

Tiptop follows strict global quality standards (ANSI, ASME, API, DIN, and ISO) to manufacture premium power generation components. Our large forging presses, advanced heat treatment facilities, and precision machining capabilities ensure every product meets international benchmarks for performance and safety.

Thermal Power Generation:

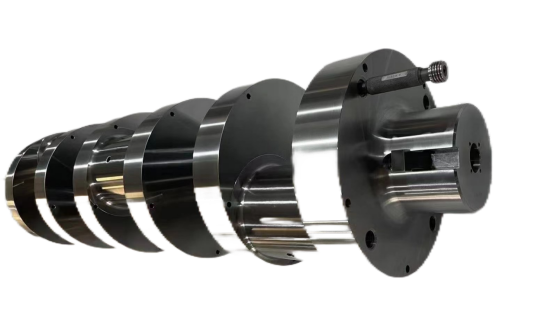

Steam Turbine Rotor Forgings:

Ultra-high purity steel, large-scale, complex profile forgings (HP/IP Rotors, LP Rotors, Generator Rotors). Production of rotors for 1000MW-class ultra-supercritical (USC) units necessitates a 12,000-ton press. Requires exceptional high-temperature creep strength, rupture strength, low-cycle fatigue (LCF) resistance, and homogeneity.

Steam Turbine Casing Forgings (Inner/Outer):

Large, complex-shaped, high-temperature & high-pressure resistant forgings (often produced as multi-segment, forged-welded assemblies).

Steam Turbine Valve Forgings:

High-temperature & high-pressure forged valve bodies (e.g., Main Stop Valves, Control Valves).

Generator Rotor Forgings:

Large-scale forgings demanding high magnetic permeability and uniformity (often comparable in size/grade to steam turbine rotors).

Generator Retaining Ring Forgings:

Large ring forgings requiring extremely high strength and stress corrosion cracking (SCC) resistance (utilizing special alloys and forming processes).

Hydroelectric Power Generation:

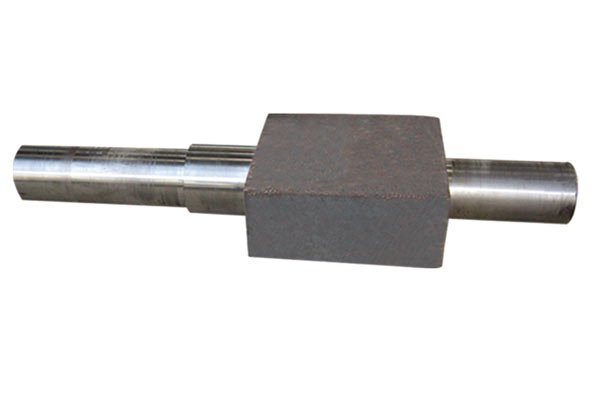

Hydraulic Turbine Main Shaft Forgings

Extra-long, large-diameter shaft forgings designed to transmit immense torque and axial thrust.

Generator Shaft Forgings

Similar requirements to Hydraulic Turbine Main Shaft Forgings, critical for large units.

Generator Rotor Spider Forgings

Large, complex-structure center hub / segment forgings or forged-welded assemblies.

Wind Power Generation:

Main Shaft

Wind Turbine Main Shaft (Large-sized, complex alternating load-bearing shaft forging, especially for 6MW+ onshore & offshore turbines. Core wind power forging).

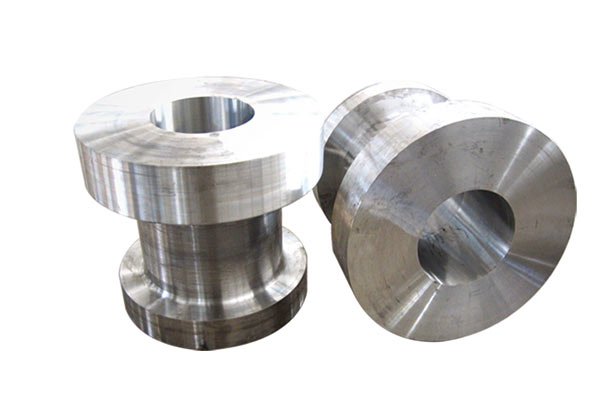

Bearing Rings

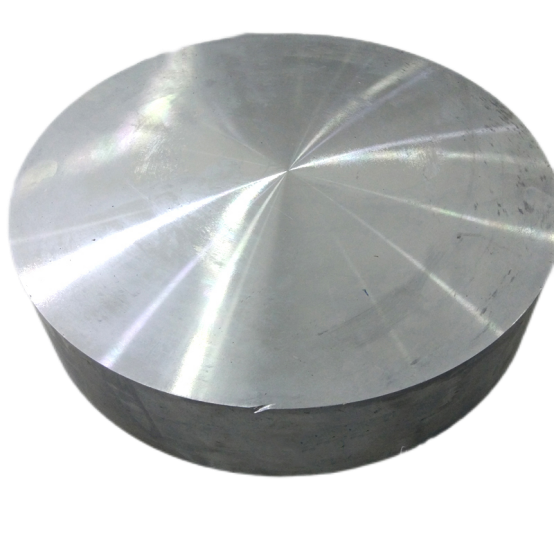

Yaw & Pitch Bearing Rings (Typically large seamless ring-rolled rings, forged from large disc blanks).

Tower Flanges

Tower Flanges (Oversized diameter, especially for offshore; high-strength ring/flange forgings).

Hub

Hub (Large, complex-shaped ductile iron castings are mainstream, but forged hubs may be explored for some designs or offshore mega-turbines - requiring extremely high press capacity)

Housings/Bases

Bearing Housings / Nacelle Bedplates (Large-sized, structural, box-type forgings).

Our power generation components are forged from ultra-high purity steel and advanced alloys, ensuring excellent creep resistance, fatigue strength, and long-term reliability under extreme operating conditions.

Tiptop offers tailored solutions across steam turbines, hydraulic turbines, wind turbines, and generators. Each component is engineered to match specific design requirements, supporting power generation equipment manufacturers worldwide.

With presses up to 12,000 tons, we produce some of the largest and most complex power generation equipment forgings, from rotors to retaining rings. This capacity enables us to support even 1000MW-class ultra-supercritical units.

All components undergo advanced inspection and testing to meet or exceed international standards. Our processes ensure uniformity, high magnetic permeability where needed, and resistance to stress corrosion cracking.

As a leading forging partner, Tiptop has established long-term cooperation with top power generation equipment suppliers and manufacturers, delivering reliable components for thermal, hydro, wind, and nuclear power projects.

Other application categories of steam turbine components

As a Chinese forging manufacturer, we at Tiptop not only provide precision forged steam turbine components and steam turbine parts to meet different categories of steam turbine systems, we also provide the following industry components to meet your various needs

The Aerospace Industry Is Renowned For Its Pursuit Of Cutting-Edge Technology And Uncompromising Safety Standards. In This Demanding Environment, Forgings Stand Out As Key Elements That Contribute To The Reliability And Performance Of Aircraft.

Forgings Play A Crucial Role In The Mining Industry, Providing Essential Components That Ensure Efficiency, Safety, And Durability In Various Mining Operations.

Oil And Gas Industry Is A Cornerstone Of The Global Energy Supply, Characterized By High Demands For Efficiency, Safety, And Resilience.

With The Development Of The Energy And Electronics Industries, The Demand For Forgings Continues To Increase. Especially In The Field Of Renewable Energy, Such As Wind Power Generation And Nuclear Power Generation, The Application Of Forgings Will Be Further Expanded.

From the enormous torque transmitted by propeller shafts to the constant hydrodynamic forces experienced by rudder systems, every component must meet the highest standards of strength, reliability, and precision. This is where marine forgings come in – providing high-performance forged products designed for durability and to extend the life of your vessel.

Pressure Vessels Are Vital Factors In A Large Vary Of Industries, From Chemical Processing To Electricity Production. Choosing The Proper Vessel Now Not Solely Ensures Operational Effectivity However Additionally Immediately Affects Safety, Compliance, And Long-Term Cost-Effectiveness.

OUR CUSTOMERS

Our ISO certificate

As an ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 certified forging manufacturer, we embody global standards for quality precision, sustainable operations and workplace safety.

Descriptions

Due to their high strength, durability and reliability, forgings are vital in the power generation industry. Whether it is thermal, hydro, nuclear, wind, solar, geothermal or biomass power generation, forged components play a fundamental role in ensuring the efficiency, safety and longevity of energy production systems.

Power Generation Industry Classifications

Thermal Power Generation: This includes power plants that use fossil fuels such as coal, natural gas, and oil.

Hydroelectric Power Generation: This category utilizes water flow, often from dams, to drive turbines and generate electricity.

Nuclear Power Generation: Nuclear plants generate power through nuclear fission, where uranium or other radioactive materials are split to release energy.

Wind Power Generation: Wind energy uses wind turbines to convert wind movement into electricity.

Solar Power Generation: Solar power plants harness energy from sunlight through photovoltaic cells or concentrated solar power systems.

Geothermal Power Generation: This form of power generation uses heat from the Earth’s core to produce steam and drive turbines.

TIPTOP Power Generation Forging Products

Turbine Components

Rotor Shafts, Blades, Rings, Flanges, Sleeves

Pressure Vessels

Headers, Steam Drums, Heat Exchanger

Generators

Generator Shafts, Stator, Rotor Assemblies, other Forgings used to build medium to large generators and motors

Compressors

Casings, Heads

Our experts have extensive experience in forging manufacturing and can design and research according to your needs

From leaders to workers, a professional team is here to protect you.

Basing on large inventory of raw materials , we can offer better prices with shorter delivery time while ensuring the highest quality forgings.

Our company has ISO 9001, ISO 14001, ISO 45001 certificates.