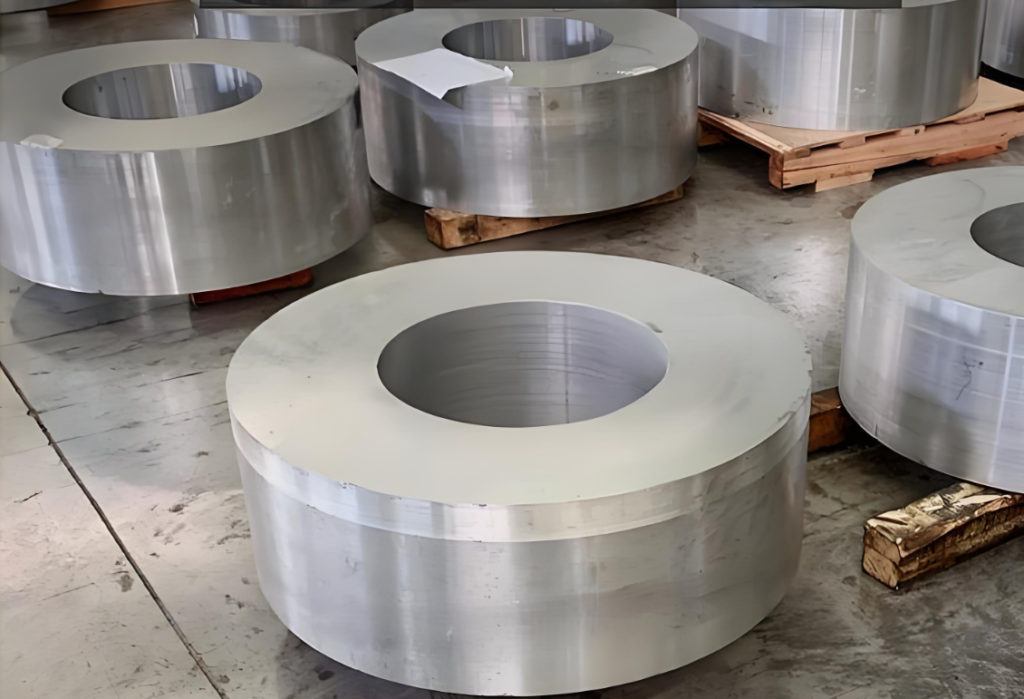

Large forged rings for industrial use are key parts of heavy-duty mechanical systems that require a high level of strength, excellent dimensional stability, and long-term reliability. One of the major advantages of forgings over fabricated or cast ones is that they have a seamless structure and a fine grain flow that enables them to withstand heavy loads, cyclic stress, and harsh environments.

Industries such as energy, mining, marine engineering, and heavy machinery rely on forged rings as a tested and safe solution.

Industrial forged rings manufacturing process

Forged rings are made by a plastic deformation process without any welding or part assembly. A solid billet is the raw material in this process which is first heated and then pierced to make a thick-walled preform. After that, the preform is shaped by forging and rolling that let the metal flow follow the circular shape of the ring.

Fabricated rings always have the problem of presence of weld seams or the existence of layered structures in the metal, however, this is not the case for forged metal rings. This manufacturing method of the ring drastically raised the level of internal continuity and mechanical strength of the material, hence forging for safety-critical and load-bearing applications is a good idea.

Ring rolling vs open die forging for large-diameter rings

Large diameter rings can be produced by either ring rolling or open die forging depending on the preference of the manufacturers. Open die forging is able to produce the ring-shaped parts, however, the dimensional accuracy of the product is mostly one of the operators’ skills and machining that is done extensively.

On the other hand, rolled ring forging will increase the diameter of the ring while decreasing the wall thickness at the same time under controlled conditions.

The parts produced using this method are nearly net-shape ones that have a uniform geometry and the material is used efficiently. This is the reason why seamless rolled ring forging is the best method for making large industrial forged rings with a consistent quality.

Seamless Ring Rolling and Grain Flow Advantages

One of the key benefits of seamless rolled ring forging is the continuous grain flow formed around the circumference of the ring. This grain orientation enhances fatigue resistance, load distribution, and impact performance.

Whether producing steel forged rings or aluminum forged rings, the seamless structure reduces the risk of internal defects and improves service life. These advantages are particularly important in rotating equipment and pressure-bearing systems where material integrity is critical.

Material Options for Forged Rings in Heavy Industry

Carbon and Alloy Steel Rings for Load-Bearing Systems

Forged steel rings are widely used in heavy industry due to their excellent strength, toughness, and wear resistance. Carbon steel and alloy steel grades are commonly selected for applications such as gear rings, bearing races, pressure vessel components, and large flanges. These forged steel ring products are designed to withstand high loads and long-term mechanical stress.

Iron and Aluminum Rings for Specialized Applications

Forged iron ring components are often used where vibration damping and durability are required. In contrast, aluminum forged rings are selected for applications where weight reduction and corrosion resistance are priorities, such as rotating assemblies and mobile equipment.

Typical Applications of Large-Diameter Forged Rings

Large industrial forged rings are used across a wide range of heavy-duty applications. Common uses include wind power bearing rings, mining machinery components, marine propulsion systems, industrial gearboxes, pressure vessels, and heavy transmission equipment. In these environments, forged rings provide reliable performance under continuous load and harsh operating conditions.

Manufacturing Capabilities of TIP TOP Forging

TIPTOP Forging is specialized in producing large industrial forged rings through controlled forging and rolled ring forging process. Being a seasoned forged rings manufacturer, we are capable of producing forged rolled rings strictly in line with customer drawings and technical requirements.

We serve a diverse array of markets and our manufacturing range is extensive and versatile, encompassing such items as forged steel rings, forged metal rings, and custom ring components. Some of the most typical ones are the oil and gas, power generation, mining, marine, and heavy machinery industries.

To guarantee the highest level of quality, we provide our customers with additional services such as heat treatment, machining, and inspection, all tailored to the performance of the ring in its specific application.

Quality Control and Dimensional Accuracy in Ring Forging

Large industrial forged rings’ performance can only be at a high level if the whole manufacturing process is/was under a very strict control. Some crucial factors such as forging temperature, deformation ratio, rolling speed, and heat treatment parameters are all thoroughly controlled to maintain a uniform grain structure and mechanical properties.

Also, dimensional inspection and non-destructive testing are carried out to ensure internal integrity and dimensional accuracy, thus, forged rings will not be a source of failure during their service life.

How to Choose a Reliable Forged Rings Manufacturer

When it comes to choosing a supplier, it is absolutely essential that the right one is selected, especially when one is dealing with large industrial forged rings. An experienced manufacturer should have knowledge of the production of large-diameter rings, should be able to select the appropriate materials, and control the forging and rolling processes.

By partnering with well-established rolled ring forging suppliers such as TIP TOP Forging, you will be able to lower your technical risk and also be sure that the forged rings are designed both for high performance and cost efficiency.

Conclusion: Why Forged Rings Remain the Preferred Choice

Manufacturing of large industrial forged rings has been, and still is, mainly via components which are forged, sometimes in conjunction with a seamless rolled ring forging process, their advantages in terms of strength, durability, and dimensional stability, as compared with fabricated and cast alternatives, being the most convincing ones.

TIP TOP Forging combines tried-and-tested manufacturing technologies with a grounded industrial knowledge to offer its clients the highly dependable large industrial forged rings that have been specifically engineered for operating environments in the real world.