AISI 4340

AISI 4340 is a high-strength, low-alloy steel widely used in forged components due to its excellent toughness, fatigue resistance, and high tensile strength. It is part of the nickel-chromium-molybdenum family and is commonly heat-treated to achieve optimal mechanical properties.

Descriptions

1. Chemical Composition

The chemical composition of AISI 4340 steel is critical to its performance. Key alloying elements include nickel, chromium, and molybdenum, which enhance hardenability and strength.

| Element | Composition Range (wt%) |

| Carbon (C) | 0.38-0.43% |

| Manganese (Mn) | 0.60-0.80% |

| Silicon (Si) | 0.15-0.30% |

| Chromium (Cr) | 0.70-0.90% |

| Nickel (Ni) | 1.65-2.00% |

| Molybdenum (Mo) | 0.20-0.30% |

| Phosphorus (P) | ≤0.025% |

| Sulfur (S) | ≤0.025% |

| Iron (Fe) | Balance |

2. Mechanical Properties

AISI 4340 exhibits exceptional mechanical properties after heat treatment (e.g., quenching and tempering). Properties vary based on processing conditions.

| Property | Typical Value | Heat Treatment Condition |

| Tensile Strength | 930-1080 MPa (135-157 ksi) | Quenched & Tempered (Q&T) |

| Yield Strength | 785-930 MPa(114-135 ksi) | Quenched & Tempered (Q&T) |

| Elongation (in 50 mm) | 12-22% | Q&T |

| Reduction of Area | Reduction of Area | Q&T |

| Charpy Impact Energy (V-notch) | 20-40J(15-30 ft-lb) | Q&T |

| Hardness (Rockwell C) | 28-35 HRC | Q&T |

| Fatigue Strength | ~500 MPa(73 ksi) | Q&T (10 cycles) |

3. Key Advantages

Superior fatigue and fracture resistance.

Excellent response to heat treatment (deep hardening).

Retains strength at elevated temperatures (up to ~400°C).

Weldable with pre-/post-heat treatment.

4. Industry-specific standards

ASTM A434: Standard specification for steel bars, alloy, hot-wrought.

AMS 6414/AMS 6415: Aerospace material specifications for Q&T steel.

DIN 1.6565: European designation for equivalent alloy.

UNS G43400: Unified numbering system code.

Recent products

High-Strength AISI 4340 Hollow Bars for Drill Pipes

AISI 4140 (42CrMo) Shaft Forging Manufacturer

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Landing gear, engine mounts, helicopter rotor components.

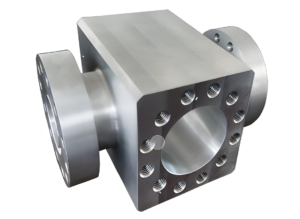

Drill collars, valve bodies, high-pressure fittings.

Drill collars, valve bodies, and pump shafts.

Heavy-duty gears, spindles, couplings.