AISI 8630

It is widely used in heavy-duty applications requiring a balance of strength, ductility, and wear resistance, particularly after heat treatment. AISI 8630 forgings are ideal for components exposed to high stress, shock loads, and cyclic environments.

Descriptions

1. Chemical Composition

AISI 8630 contains nickel, chromium, and molybdenum to enhance core toughness and hardenability, while its moderate carbon content supports heat treatment.

| Element | Composition(% by Weight) | Role |

| Carbon (C) | 0.28-0.33 | Provides base strength and hardness. |

| Manganese (Mn) | 0.70-0.90 | Improves hardenability and deoxidizes steel. |

| Silicon (Si) | 0.15-0.35 | Strengthens ferrite and improves cleanliness. |

| Silicon (Si) | 0.40-0.70 | Enhances core toughness and impact resistance. |

| Chromium (Cr) | 0.40-0.60 | Boosts hardenability and wear resistance. |

| Molybdenum (Mo) | 0.15-0.25 | Improves strength and creep resistance. |

| Phosphorus (P) | 0.035 max | Controlled impurity (minimizes brittleness). |

| Sulfur (S) | 0.040 max | Controlled impurity (improves machinability). |

| Iron (Fe) | Balance | Base metal. |

2. Mechanical Properties

AISI 8630 forgings achieve optimal performance through heat treatment (e.g., quenching and tempering). Properties vary based on processing methods.

| Property | Normalized | Quenched &Tempered | As-Forged | Test Standard |

| Tensile Strength | 620-795MPa | 900-1080 MPa | 550-700MPa | ASTM E8 |

| Yield Strength (0.2% offset) | 415-585MPa | 750-950MPa | 350-500MPa | ASTME8 |

| Elongation (% in 50mm) | 18-22% | 12-18% | 15-20% | ASTME8 |

| Reduction of Area | 50-60% | 45-55% | 40-50% | ASTM E8 |

| Hardness (Brinell) | 197-235HB | 285-341HB | 170-210HB | ASTME10 |

| Impact Toughness(Charpy V) | 50-80J(room temp) | 40-60J | 60-90J | ASTM E23 |

| Fracture Toughness(K<sub>IC</sub>) | 110-140MPaVm | 90-120 MPa√m | N/A | ASTME399 |

3. Key Advantages

High Core Toughness: Nickel content ensures resistance to impact and shock loads.

Heat Treatability: Tailored strength and hardness via quenching, tempering, or carburizing.

Fatigue Resistance: Performs well under cyclic stress (e.g., rotating machinery).

Weldability: Suitable for welding with pre-/post-heat treatment to prevent cracking.

4. Typical Forging Product

Forged Drill Collars

Heavy-Duty Axle Shafts

Hydraulic Cylinder Rods

Turbine Rotor Components

Mining Crusher Shafts

Recent products

Magnadur 501 Non-Magnetic Drill Collar

Tubing Head Forgings for Oil and Gas Wellhead Equipment

API 6A Studded Cross

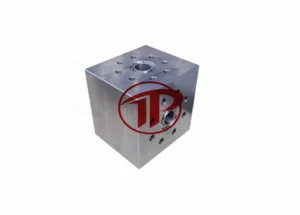

Forged blocks used as valve bodies

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Landing gear components, engine mounts, structural fittings.

Axle shafts, crankshafts, and transmission gears.

Drill collars, tool joints, blowout preventer (BOP) components.

Turbine shafts, high-pressure valve bodies.