AISI 1020

While it lacks the high strength of alloy or medium-carbon steels, its affordability and versatility make it a popular choice for forged components in industries requiring moderate strength and ease of fabrication, including oil & gas, mining (coal), and general machinery.

Descriptions

1. Chemical Composition

AISI 1020 complies with the following composition (weight %):

| Element | Content (%) |

| Carbon (C) | 0.18-0.23 |

| Manganese (Mn) | 0.30-0.60 |

| Phosphorus (P) | ≤0.040 |

| Sulfur (S) | ≤0.050 |

| Silicon (Si) | ≤0.40 |

| Iron (Fe) | Balance |

2. Mechanical Properties

Properties vary slightly based on forging process and heat treatment. Typical values for hot-forged and normalized AISI 1020:

| Property | Value |

| Tensile Strength | 380-550 MPa(55-80ksi) |

| Yield Strength | 210-350 MPa(30-51 ksi) |

| Elongation (50mm) | 15-25% |

| Hardness | 110-170 HB (Brinell) |

| Impact Energy (Charpy V-notch) | 20-40J(15-30 ft-1b) at 20°C |

3. Key Advantages

Excellent Weldability: Suitable for on-site repairs and modifications.

Cost-Effective: Lower material and processing costs compared to alloy steels.

Machinability: Easy to machine into complex shapes with standard tools.

Ductility: Resists fracture under bending or forming operations.

4. Limitations

Low Strength: Not suitable for high-stress or dynamic-load applications (e.g., drill collars, crusher jaws).

Poor Wear Resistance: Requires surface treatments (e.g., carburizing) for abrasive environments.

Corrosion Susceptibility: Needs coatings (galvanizing, painting) for outdoor or humid conditions.

Recent products

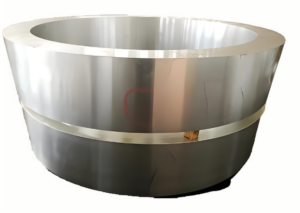

Top Drive Inner Barrel

Aluminum Forgings for Aerospace Applications

Large Ring Gear Forgings

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Standards & Certifications

ASME B16.5 (Pipe Flanges and Flanged Fittings).

API 6A (Limited to non-critical components).

Applications

Piping and Fittings:

Low-pressure pipe flanges, couplings, and valve bodies.

Structural Supports:

Brackets, base plates, and lifting lugs for platforms and drilling rigs.

Fasteners:

Bolts, studs, and nuts for assembly of non-pressure-retaining systems.

Tooling Components:

Jigs, fixtures, and temporary supports for maintenance operations.

Material Handling Systems:

Conveyor rollers, shafts, and brackets for coal transport equipment.

Mining Machinery:

Non-wear parts like gear blanks, linkage arms, and hydraulic cylinder rods.

Support Structures:

Reinforcements for mine carts, ventilation ducts, and tunnel bracing.

Safety Equipment:

Frames for lighting rigs, sensor mounts, and emergency tool housings.