AISI 1117

AISI 1117 is a low-carbon, free-machining steel classified under the ASTM A29/A108 standard

Descriptions

1. Chemical Composition

The typical chemical composition (weight percentage) is:

| Element | Content (%) |

| Carbon (C) | ≤0.27 |

| Manganese (Mn) | 1.00-1.30% |

| Phosphorus (P) | 0.08-0.13% (key for machinability) |

| Sulfur (S) | ≤0.04% |

| Iron (Fe) | Balance |

2. Mechanical Properties

Forging refines the grain structure, enhancing strength and durability. Typical mechanical properties for AISI 1117 forgings (annealed or normalized):

| Property | Value |

| Tensile Strength | 540-620 MPa(78-90ksi) |

| Yield Strength | 415-485 MPa(60-70 ksi) |

| Elongation | 20-25%(in 50 mm) |

| Hardness | 160-200 HB(Brinell) |

| Impact Energy (Charpy V-notch) | ~25-35 J(moderate, limited by sulfur content) |

3. Key Advantages

Excellent machinability (ideal for CNC or automatic lathes).

Cost-effective for high-volume production.

Good surface finish post-machining.

4. Limitations

Poor weldability (sulfur causes hot cracking).

Lower ductility and impact resistance compared to non-sulfurized steels (e.g., AISI 1018).

Limited use in high-stress or corrosive environments.

Recent products

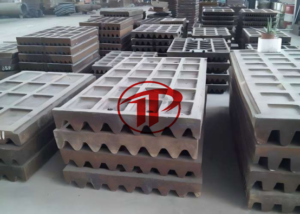

Jaw Plate

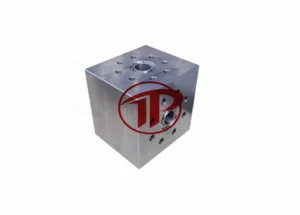

Quill Forging For Top Drive System

P650 Non-Magnetic Drill Collar for MWD/LWD

API 6A Studded Cross

Forged Crusher Hammer for Mining

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Standards & Certifications

ASTM A108: Standard specification for steel bar, carbon, free-machining.

SAE J403: Chemical composition requirements.

ISO 683-1: Equivalent grade (11SMn30).

Applications

Shafts, gears, and pinions Engine components (e.g., camshafts, connecting rods) Fasteners (bolts, studs)

Bushings, couplings, and valve bodies Tool holders and jigs

Hydraulic fittings, flanges, and threaded rods Low-stress structural parts