303 stainless steel

It is a free-machining austenitic stainless steel widely used in applications requiring high machinability and moderate corrosion resistance.

Descriptions

1. Chemical Composition

The chemical composition of 303 stainless steel is specified below:

| Element | Composition (%) |

| Chromium (Cr) | 17.0-19.0 |

| Nickel (Ni) | 8.0-10.0 |

| Manganese (Mn) | ≤2.00 |

| Silicon (Si) | ≤1.00 |

| Carbon (C) | ≤0.15 |

| Phosphorus (P) | ≤0.20 |

| Sulfur (S) | ≥0.15(min) |

| Iron (Fe) | Balance |

2. Mechanical Properties

Typical mechanical properties of 303 stainless steel forgings (annealed condition):

| Property | Value |

| Tensile Strength | 515-620 MPa (75,000-90,000psi) |

| Yield Strength(0.2% offset) | 205 MPa (30,000 psi) |

| Elongation at Break | 40%-50% |

| Hardness (Rockwell B) | 85-95 HRB |

| Modulus of Elasticity | 193 GPa (28 x 10⁶ psi) |

| Density | 8.03 g/cm³ (0.289 1b/in³) |

| Melting Point | 1400-145°C(2550-2640°F) |

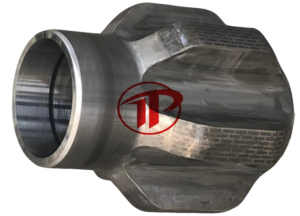

3. Common Forging Product

303 Forged Bars/Rods

303 Forged Flanges

303 Forged Fittings

303 Forged Shafts

303 Forged Valve Bodies

4. Industry standards

ASTM A582: Standard Specification for Free-Machining Stainless Steel Bars.

ASTM A484: General Requirements for Stainless Steel Bars, Billets, and Forgings.

AMS 5640: Aerospace Material Specification for 303 Stainless Steel Bars and Rods.

EN 10088-3: European Standard for Stainless Steels – Technical Delivery Conditions for Semi-Finished Products, Bars, Rods, and Sections.

ISO 3506: Mechanical Properties of Corrosion-Resistant Stainless Steel Fasteners.

Recent products

API7-1 4145H Stabilizer Sleeve Forging

Hydropower Main Shaft Forging

Jaw Crusher Shaft Forging

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Non-critical structural parts and fittings.

: Shafts, valve components, and fasteners.

Gears, couplings, and pump components.