422 stainless steel

422 stainless steel forgings are critical for high-stress, high-temperature environments, offering a unique combination of martensitic strength, thermal stability, and corrosion resistance. Their compliance with aerospace and industrial standards ensures reliability in turbines, power plants, and oil/gas equipment.

Descriptions

1. Chemical Composition

The composition of 422 stainless steel includes chromium, molybdenum, and tungsten to enhance high-temperature strength and oxidation resistance:

| Element | Composition (%) |

| Carbon (C) | 0.20-0.25 |

| Manganese (Mn) | ≤1.00 |

| Silicon (Si) | ≤0.75 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.025 |

| Chromium (Cr) | 11.00-13.00 |

| Nickel (Ni) | 0.50-1.00 |

| Molybdenum (Mo) | 0.75-1.25 |

| Tungsten (W) | 0.75-1.25 |

| Vanadium (V) | 0.20-0.30 |

| Iron (Fe) | Balance |

2. Mechanical Properties

422 stainless steel forgings achieve optimal performance after heat treatment (quenching and tempering). Properties vary between annealed and heat-treated conditions:

Annealed Condition

| Property | Value |

| Tensile Strength | 690 MPa (100,000 psi) |

| Yield Strength(0.2% offset) | 515 MPa (75,000 psi) |

| Elongation (50 mm gauge) | 18% |

| Hardness (Brinell) | 212-248HB |

| Modulus ofElasticity | 200 GPa(29 x10⁶psi) |

| Density | 7.76 g/cm³(0.280 1b/in³) |

| Melting Range | 1425-1510°C(2597-2750°F) |

Heat-Treated Condition (Quenched & Tempered)

| Property | Value |

| Tensile Strength | 1035-1240 MPa (150,000-180,000psi) |

| Yield Strength (0.2% offset) | 860-1035 MPa (125,000-150,000 psi) |

| Elongation (50 mm gauge) | 12-15% |

| Hardness (Rockwell C) | 28-35 HRC |

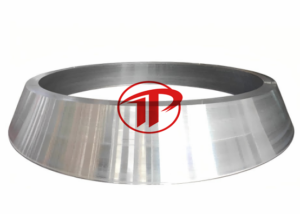

3. Common Forging Product

Forged Turbine Blades

Forged Compressor Disks

Forged Valve Bodies

Forged Shafts

Forged Fasteners

4. Key Advantages

High-Temperature Stability: Retains strength and resists creep at temperatures up to 650°C.

Oxidation Resistance: Forms a protective chromium oxide layer.

Machinability: Can be machined in the annealed condition and hardened post-processing.

5. Industry standards

Standard | Scope |

ASTM A565/A565M | Martensitic stainless steel bars for high-temperature service. |

AMS 5619 | Aerospace-grade 422 stainless steel bars and forgings. |

ASTM A473 | Stainless steel forgings (general applications). |

ASME SA565 | ASME Boiler and Pressure Vessel Code compliance. |

EN 10088-3 | Technical delivery conditions for semi-finished products. |

Recent products

API 6A AISI 4130 Forged Steel Round Hollow Bar

Large Ring Gear Forgings

7050 2024 Aerospace Aluminum Forging

Aerospace Spacecraft Interior Components

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Turbine blades, compressor disks, and jet engine components.

Steam turbine blades, bolts, and high-pressure valve parts

Downhole tools, wellhead components, and drilling equipment.

Combustion cans, rotor shafts, and exhaust systems.