NITRONIC® 50 (UNS S20910)

NITRONIC® 50 stainless steel forgings are a premium choice for demanding applications in aerospace, marine, and energy industries. Their unique nitrogen-strengthened composition, combined with excellent corrosion and wear resistance, ensures long-term performance in extreme conditions. Compliance with ASTM, AMS, and NACE standards guarantees reliability for critical engineering applications.

Descriptions

1. Chemical Composition

The unique composition of NITRONIC® 50 includes nitrogen for strength and reduced nickel content for cost efficiency:

| Element | Composition (%) |

| Carbon (C) | ≤0.06 |

| Chromium (Cr) | 20.50-23.50 |

| Nickel (Ni) | 11.50-13.50 |

| Manganese (Mn) | 4.00-6.00 |

| Silicon (Si) | ≤1.00 |

| Nitrogen (N) | 0.15-0.30 |

| Molybdenum (Mo) | 1.50-3.00 |

| Vanadium (V) | 0.10-0.30 |

| Iron (Fe) | Balance |

2. Mechanical Properties

NITRONIC® 50 stainless steel forgings exhibit superior strength-to-weight ratios compared to conventional austenitic grades (e.g., 304, 316). Typical properties in the solution-annealed condition are:

Room Temperature Properties

| Property | Value |

| Tensile Strength | 760-895 MPa(110,000-130,000psi) |

| Yield Strength(0.2% offset) | 415-550 MPa (60,000-80,000psi) |

| Elongation (50 mm gauge) | 35-45% |

| Hardness (Rockwell B) | 95-100 HRB |

| Modulus of Elasticity | 193 GPa (28x 10⁶ psi) |

| Density | 7.8 g/cm³(0.282 1b/in³) |

| Melting Range | 1370-1420℃(2500-2590°F) |

Heat-Treated Condition (Quenched & Tempered)

Condition | Yield Strength (0.2% offset) |

-196°C (-320°F) | ≥ 690 MPa (100,000 psi) |

600°C (1112°F) | ≥ 345 MPa (50,000 psi) |

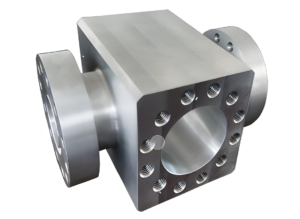

3. Common Forging Product

Forged Shafts

Forged Valves

Forged Fasteners

Forged Pump Components

Forged Aerospace Actuators

4. Key Advantages

High Strength: Exceeds conventional austenitic steels (e.g., 2x stronger than 316L).

Corrosion Resistance: Resists pitting, crevice corrosion, and stress corrosion cracking (SCC).

Wear Resistance: Superior galling resistance due to nitrogen hardening.

Cost Efficiency: Lower nickel content reduces material costs compared to high-nickel alloys.

5. Industry standards

Standard | Scope |

ASTM A276/A276M | Stainless steel bars and shapes. |

ASTM A473 | Stainless steel forgings (general). |

AMS 5893 | Aerospace-grade bars, forgings, and rings. |

ASME SA276/SA276M | ASME Boiler and Pressure Vessel Code. |

EN 10088-3 | Technical delivery conditions for bars and rods. |

NACE MR0175/ISO 15156 | Compliance for sour service environments. |

Recent products

Titanium Alloy Rotor Sleeve

API 6A Valve Body Forging

API 8C 4145H Top Drive Main Shaft Forging

CONTACT US

Address

B-2007,Chuanmei Building,Taishan Street,Taian City,Shandong, China

Call Us

+86 0538 6368027

Email Address

Sales@tiptopforging.com

Applications

Landing gear components, actuator shafts, and fasteners. Jet engine parts exposed to high stress and oxidation.

Steam turbine blades, bolts, and high-pressure valve parts

Downhole tools, wellhead equipment, and subsea connectors.

Combustion cans, rotor shafts, and exhaust systems.