Why Mining Forgings Are Critical to Equipment Performance

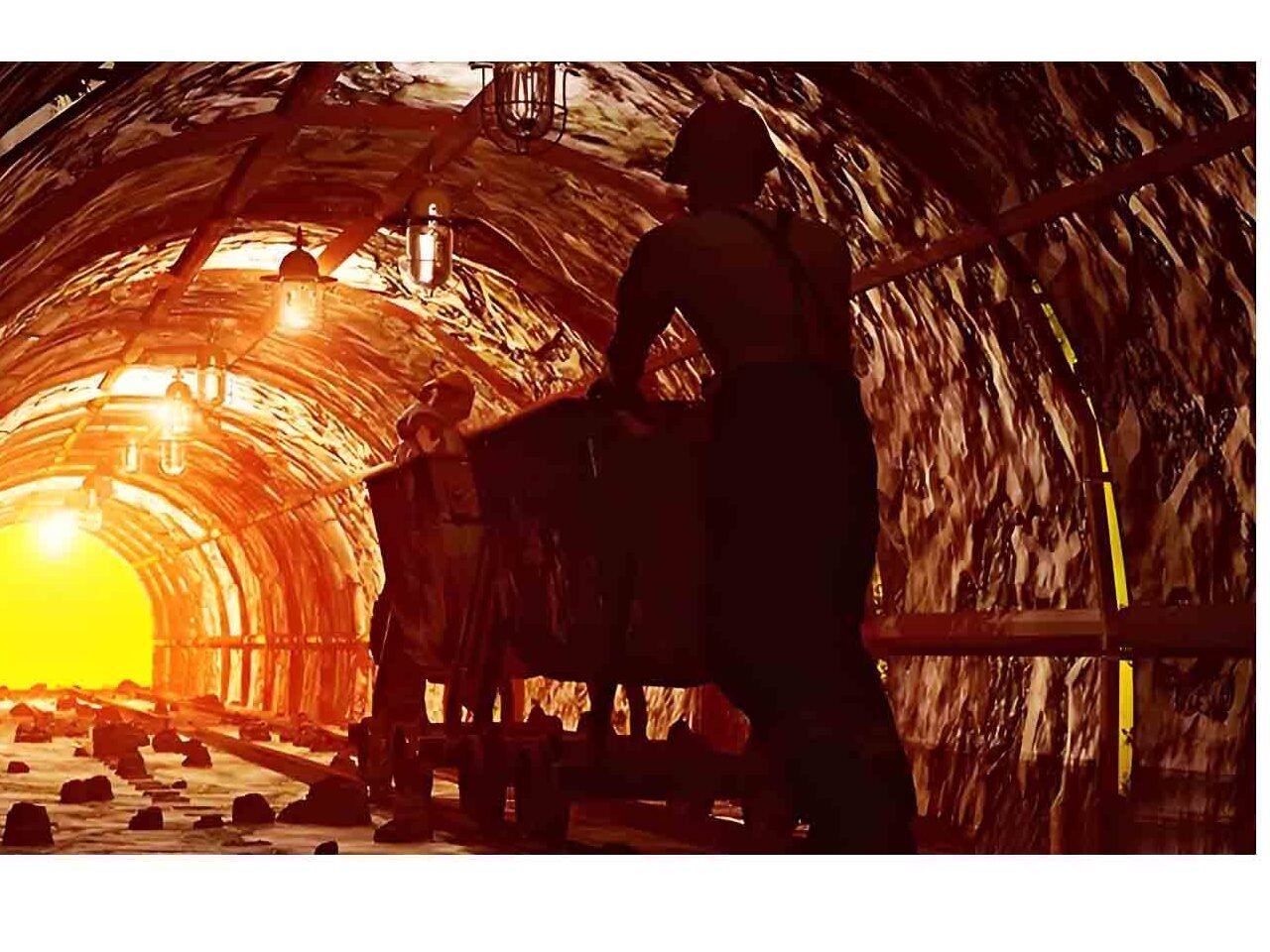

The mining enterprise operates in some of the most harsh environments on the planet. From deep underground to high-altitude open-pit sites, gear is pushed to its limits underneath intense pressure, load, and temperature. That’s why mining forging has turn out to be the go-to answer for producing durable, high-performance components for mining machinery.

Unlike forged or welded parts, forged steel parts for mining supply unmatched strength, fatigue resistance, and structural integrity—qualities indispensable for dependable operation in mission-critical applications.

What Is Mining Forging?

Mining forging is the method of shaping heated metal—typically carbon steel, alloy steel, or stainless steel—under excessive strain to create elements used in mining equipment. These mining forgings are greater and greater wear-resistant than their forged or machined counterparts, making them perfect for annoying applications.

Leading mining forgings manufacturers supply forged parts for a wide range of equipment, including:

Shovels and excavators

Grinding mills

Hoisting systems

Crushers

Haul trucks

Core Mining Forged Parts by Equipment Category

1. Critical Forged Components for Mining Shovels and Excavators

Large electric or hydraulic shovels rely heavily on robust mining forged parts to ensure safe and effective digging and material handling. We supply:

Dipper Handle Forgings – for structural stability under dynamic loading

Stick Forgings – to transmit force from the boom to the dipper

Boom Forgings – engineered for heavy lifting and long-term reliability

Track Frame Forgings – built to endure harsh terrain and heavy wear

Slewing Ring Forgings – enabling stable 360° movement under high torque

2. Mining Forgings for Ball Mills and SAG Mills

Heavy-duty grinding equipment such as large ball mills or semi-autogenous grinding (SAG) mills requires large-scale, stress-resistant forgings:

End Cover Forgings – sealing the mill while absorbing structural load

Trunnion Forgings – serving as the rotary support axis

Girth Gear Forgings – transmitting torque for mill rotation

These large mining forging components are essential to the mill’s safe and continuous operation.

3. Mining Forgings for Hoists and Winders

Hoisting systems are vital for transporting materials and personnel in underground mining. Our forged products include:

Main Shaft Forgings – handling vertical load and dynamic stress

Drum Forgings – providing strong cable support and smooth winding

Large Gear Forgings – ensuring efficient power transmission

These mining machinery forgings are manufactured with tight tolerances and advanced heat treatment to ensure optimal performance.

4. Forged Parts for Gyratory and Cone Crushers

Crushers are responsible for the primary size reduction of mined material. Their components endure high impact and abrasion. Our offerings include:

Frame Forgings – maintaining structural integrity under intense load

Main Shaft Forgings – central rotating components for crushing force

Head and Mantle Forgings – withstanding cyclic crushing and wear

5. Forged Steel Parts for Large Haul Trucks

In surface mining, haul trucks are crucial for transporting raw material. Forged components ensure these massive vehicles operate safely:

Critical Frame Connection Forgings – absorbing torsional stress across the chassis

Large Suspension System Forgings – supporting heavy payloads across rough terrain

Benefits of Forged Steel Parts in Mining

Enhanced Strength & Fatigue Resistance

Forgings exhibit a continuous grain flow aligned to the part’s geometry, resulting in significantly greater mechanical strength compared to castings or weldments.

Improved Operational Safety

With higher load-bearing capacity and fewer failure points, forged parts minimize the risk of catastrophic breakdowns in the field.

Extended Equipment Lifespan

Mining forged parts typically last longer, lowering total cost of ownership and minimizing unplanned downtime.

Partner with a Trusted Mining Forgings Manufacturer

As a leading mining forgings manufacturer, we specialize in producing high-quality custom forgings for the mining industry. Our production capabilities support:

Large mining forging projects (over 20 tons per piece)

Complex geometries and taper transitions

Strict mechanical and metallurgical testing per ASTM, ASME, ISO standards

One-stop options from forging, tough machining, warmth remedy to end machining

Whether you want forged steel components for mining shovels, mills, crushers, or hoisting systems, we supply precision-engineered elements you can depend on.

Conclusion: Forge Mining Success with Reliable Forged Components

In an enterprise the place downtime capability misplaced revenue, exceptional mining forgings are no longer optional—they’re essential. From stick forgings to important shafts, investing in expertly manufactured forged components ensures more advantageous performance, longer life, and higher returns.