Description

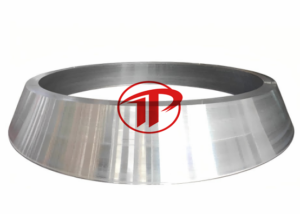

Product Introduction – 4130 Alloy Steel Drill Collar for Oil & Gas Drilling

4130 alloy steel drill collar forgings are critical pressure-bearing and counterweight components used in collar drilling systems for oil and gas operations. Positioned between the drill collar drill pipe assembly and the drill bit, the drilling collar provides consistent weight on bit (WOB), stabilizes the drill string, and supports the reliable operation of downhole power tools.

Manufactured from high-quality alloy steels, our 4130 drilling collars are produced through precision open-die forging combined with controlled heat treatment. This process ensures an optimal balance of strength, toughness, and fatigue resistance—key requirements for long service life in demanding drilling environments.

4130 drill collars are a cost-effective steel alloy solution that has been widely applied in conventional wells, deep wells, as well as standard directional drilling work.

If you choose TIPTOP, you will be dealing with a professional forging manufacturer who has a deep understanding of steel as an alloy and its performance in real drilling conditions. Our engineering team is always ready to give you technical support at any stage of the process from material selection, forging design, to application guidance, thus ensuring the operational reliability of the equipment.

Core Material – AISI 4130 Chromium-Molybdenum Alloy Steel

AISI 4130 is a medium-carbon alloyed steel that comes under the family of chromium-molybdenum steel alloys. The presence of chromium and molybdenum improves the properties of steel significantly in terms of strength, hardenability, weldability, and fatigue resistance, thus, it has become the preferred alloy steel grade in the drilling collar industry.

Mechanical tests have revealed that 4130 not only outperforms plain carbon steel but also remains stable under cyclic loads and torsional stress, which are typical in drill collar and drill collar slips contact zones during tripping and drilling operations.

Typical Chemical Composition (%) of 4130 Alloy Steel Drill Collar

| Element | C | Cr | Mo | Si | Mn | P | S | V | Ni |

| Required | 0.28–0.33 | 0.75–1.10 | 0.35–0.50 | 0.15–0.35 | 0.75–1.00 | ≤0.015 | ≤0.005 | 0.05–0.10 | 1.65–3.00 |

| Actual | 0.31 | 0.85 | 0.43 | 0.24 | 0.82 | 0.009 | 0.001 | 0.08 | 2.15 |

Mechanical Properties of 4130 Drill Collar Forgings (ASTM A370)

Sampling location: Longitudinal, 55 mm below surface

| Property | Yield Strength | Tensile Strength | Elongation A% | Reduction of Area % |

| Unit | PSI / MPa | PSI / MPa | % | % |

| Minimum Required | 110,000 / ≥758 | 140,000 / ≥965 | ≥14 | ≥45 |

| Actual Result | 161,276 / 1112 | 173,459 / 1196 | 17.0 | 55 |

These results confirm that 4130 alloy steel drill collars exceed standard mechanical requirements, ensuring reliable performance under high axial load and rotational stress.

Drill Collar Product Classification and Types

Different drilling environments require different drill collar designs. Based on structural form and functional requirements, TIPTOP supplies multiple drilling collar solutions:

Classified by Structure

Conventional drill collars

Spiral drill collars (improved cuttings removal and reduced differential sticking)

Adjustable stabilizer drill collars

Classified by Function and Material

Non-magnetic drill collars: Manufactured from special non-magnetic steel alloys such as P530, P550, and P650 for MWD/LWD operations

High-strength drill collars: Produced from higher-grade alloy steels like 4140H and 4145H, suitable for ultra-deep wells and high drilling loads

Main Applications of 4130 Alloy Steel Drilling Collars

Oil and Gas Drilling

As a rigid and heavy component of the drill string, the drilling collar provides essential weight and stability in vertical, directional, and extended-reach wells.

Geological Exploration & Geothermal Drilling

4130 drill collars offer reliable downhole support in mineral exploration and geothermal well construction.

Well Intervention and Completion Operations

Used as heavy drilling collars in milling, casing window cutting, and other high-load well intervention activities.

Applicable Conditions

Thanks to its balanced mechanical performance and cost efficiency, 4130 alloy steel drill collars are particularly suitable for:

Medium-deep wells (≤ 4500 m)

Conventional directional drilling

Non-extreme corrosive environments

Standard Size Specifications of Drill Collar (API)

Drill collar dimensions are defined by outer diameter (OD), inner diameter (ID), length, and API connection threads. The following sizes comply with API standards; customization is available upon request.

| Nominal OD (inch) | OD Range (mm) | Common ID (mm) | API Connection Thread | Single Length (m) |

| 4-3/4″ | 120.7 ± 1.6 | 50.8–57.2 | NC35, NC38 | 9.1–9.5 |

| 6-1/4″ | 158.8 ± 2.0 | 57.2–71.4 | NC44, NC46 | 9.1–9.5 |

| 6-1/2″ | 165.1 ± 2.0 | 57.2–71.4 | NC46, NC50 | 9.1–9.5 |

| 7″ | 177.8 ± 2.0 | 57.2–71.4 | NC50 | 9.1–9.5 |

| 8″ | 203.2 ± 2.4 | 71.4–76.2 | NC56, NC61 | 9.1–9.5 |

| 9″ | 228.6 ± 2.4 | 76.2–101.6 | NC61, NC70 | 9.1–9.5 |

| 10″ | 254.0 ± 2.4 | 101.6–114.3 | NC70, NC77 | 9.1–9.5 |

Why Choose TIPTOP as Your Drill Collar Forging Manufacturer?

Going with TIPTOP means that you choose a trusted partner with a focus on drill collar and drilling collar forgings for the world oil and gas market.We center our attention on high-end alloy steel forgings and we are very familiar with making drill collars, stabilizers, and various downhole components.Our technical team—material scientists, forging engineers, and heat treatment specialists—are together capable of providing the whole range of services starting from steel alloy selection and forging process design to performance optimization.With consistent quality control, experience in international delivery, and an efficient technical service, TIPTOP is delighted to establish long-term and mutually beneficial relationships with drilling contractors and equipment suppliers throughout the .

📩 Please don’t hesitate to get in touch with us in case you want to talk about your drill collar specifications, custom alloy steel requirements, or project-specific drilling challenges.

Reviews

There are no reviews yet.