Description

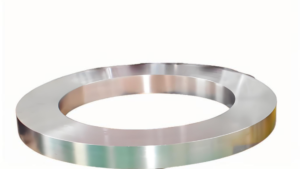

Product Introduction – 4145H Stabil Drill for Oil Drilling

The 4145H stabilizer forging is a critical drilling stabilizer used in modern oil and gas drilling operations. Manufactured in accordance with international standards such as API Spec 7-1, this stabil drill is designed to centralize and stabilize the drill collar and drill pipe at the bottom of the drill string.

By optimizing the stabilizer drilling configuration, it effectively controls well deviation, improves borehole quality, and ensures efficient and safe drilling operations. As a key drill pipe stabilizer, it plays an essential role in maintaining directional control during both vertical and directional drilling.

Our drilling stabilizers feature an optimized spiral blade design that provides strong centering force and high operational stability. During rotation, the stabilizer also assists in cuttings transport and wellbore wall cleaning, reducing the risk of differential sticking and stuck pipe. Choosing TIPTOP stabilizers drilling solutions means choosing a professional technical team that supports you throughout manufacturing, operation, and maintenance.

Core Material – 4145H Alloy Steel for Drilling Stabilizers

The main body of this drilling stabilizer forging is manufactured from strictly certified 4145H medium-carbon chromium-molybdenum alloy steel. Both chemical composition and mechanical properties comply with API 7-1 and other international drilling standards, ensuring reliable performance under high torque, cyclic loading, and impact conditions commonly encountered in stabilizer drilling applications.

Typical Chemical Composition of 4145H Alloy Steel (%)

| C | Si | Mn | S | P | Cr | Mo | Cu | Ni | Al |

| 0.45 | 0.26 | 1.15 | 0.006 | 0.009 | 1.21 | 0.31 | 0.02 | 0.01 | / |

Mechanical Properties of 4145H Stabilizer Drilling Components

The optimized alloy composition of 4145H provides an excellent balance between strength and toughness, making it particularly suitable for stabil drill tools operating in demanding downhole environments where fatigue resistance and impact toughness are critical.

| Item | Specified | Result |

| Yield Strength Rp0.2 (MPa) | ≥ 758 | 922 |

| Tensile Strength Rm (MPa) | ≥ 965 | 1049 |

| Elongation A (%) | ≥ 13 | 17 |

| Reduction of Area Z (%) | ≥ 45 | 56 |

| Charpy Impact AkV (J) @ 20°C | ≥ 54 | 85 / 80 / 82 |

| UT / MT Standard | ASTM E213 / ASTM E3024 | Qualified / Pass |

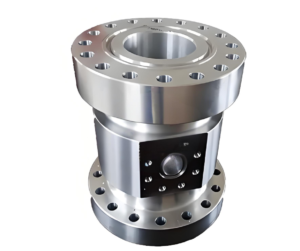

Precision Manufacturing Process for Drill Pipe Stabilizer Forgings

To guarantee consistent quality and long service life, TIPTOP applies strict and traceable manufacturing processes for all drill pipe stabilizer forgings.

Forging Process for Drilling Stabilizers

High-quality 4145H alloy steel bars are selected and inspected before forging. Advanced hot die forging or hot extrusion techniques are used to form the stabilizer blank, significantly enhancing internal structure density, impact resistance, and fatigue life compared with machined stabilizers.

Heat Treatment for Stabilizer Drilling Tools

After forging, stabilizers drilling components undergo controlled quenching and tempering processes to achieve stable mechanical properties, ensuring the drilling stabilizer maintains strength and toughness throughout extended downhole service.

CNC Machining and Thread Accuracy

Large CNC machining centers are used to ensure dimensional accuracy, surface finish, and precise threaded connections, which are critical for safe and reliable integration of the stabil drill into the drill string.

Wear-Resistant Treatment for Stabilizers Drilling Applications

Wear-resistant bands (HF1000–HF5000) can be applied according to drilling conditions. This treatment significantly improves abrasion resistance in hard and abrasive formations, extending the service life of drilling stabilizers and reducing overall drilling costs.

Applications of Drilling Stabilizers and Stabil Drill Tools

4145H drilling stabilizers are widely applied in:

Onshore and offshore oil and gas drilling operations

Full-gauge stabilizer drilling assemblies for deviation prevention

Pendulum drilling assemblies for inclination correction

Deep hole drilling projects including geological exploration and geothermal drilling

As a critical drill pipe stabilizer, this tool ensures directional stability and improved drilling efficiency across various formations.

Why Choose TIPTOP Drilling Stabilizers

TIPTOP specializes in high-performance drilling stabilizer forgings manufactured from premium 4145H alloy steel. Through advanced forging, heat treatment, and surface hardening technologies, our stabilizers drilling products deliver high strength, excellent toughness, and superior fatigue resistance.

With strict quality control, full traceability, and compliance with API standards, TIPTOP provides reliable stabil drill solutions trusted by global drilling contractors. From design support to field application, we help you achieve safer, more efficient stabilizer drilling performance.

Reviews

There are no reviews yet.