Description

1. Description

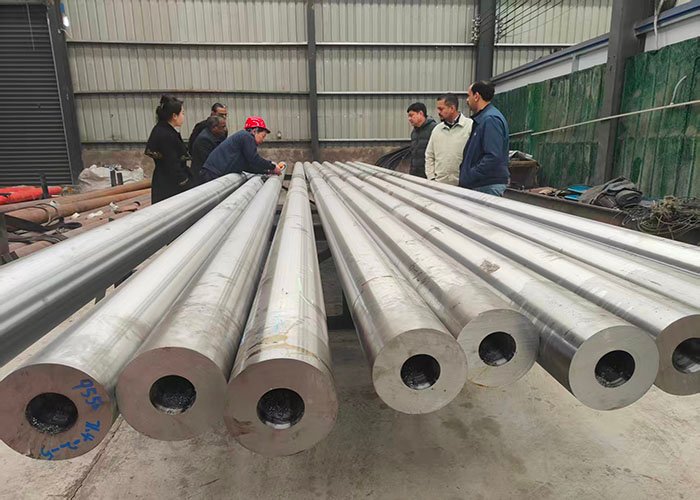

TIPTOP forging’s AISI 4145 round hollow/solid bars are manufactured for demanding, high-performance applications and kinds of industries. This material combines exceptional high tensile strength, impact resistance, and fatigue endurance.

2. AISI 4145 Typical Properties

AISI 4145 is a medium-carbon low-alloy chromium-molybdenum steel. After forging, its grain structure is refined and optimized, giving it excellent mechanical and physical properties. Our company also can meet the technical requirements specified by our clients.

ELEMENT C Cr Mo Si Mn P S

Required 0.42 to 0.48 1.1 to 1.3 0.27 to 0.35 0.2 to 0.3 1 to 1.2 0.015 max 0.01 max

Tensile Strength (MPa) Elongation (%) Hardness

≥965 ≥13 285-341

3. Application of Forged 4145 Round Bars in Drilling Industries

Our 4145 forged bars are primarily used in the production of downhole drilling tools, which withstand enormous torque, impact, and cyclic loads during drilling. The AISI 4145 bars we supply are used in the following drilling tools:

Drill Collars – As drilling tools, they require high tensile strength, stiffness, and fatigue resistance.

Stabilizers – They require excellent resistance to wellbore abrasion and high structural strength to function optimally.

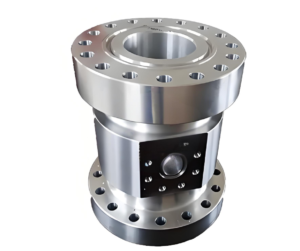

Rotary Joints – They require superior strength and fatigue life to withstand repeated connection/disconnection and varying torque to ensure operational safety.

Heavy-Duty Drill Pipe (HWDP) Connectors – They rely on good impact toughness and high strength to ensure a long service life.

4. Forged Round Bars’ Main Advantages Compared With Rolled Round Bars

More compact material

The forging process is like applying tremendous pressure to compact the interior of the metal, removing any loose voids and bubbles, thereby forming a finer and denser structure, much like a compacted dough.

Superior “steel-like” performance

Stronger: Better tensile and compressive strength.

More durable: Significantly stronger resistance to impact and repeated stress (fatigue resistance).

Uniform performance: Performance is nearly uniform from any direction (better isotropy), unlike some rolled parts that are less robust when viewed horizontally.

Longer and more reliable lifespan: Due to fewer internal defects and a better structure, it is less prone to sudden failure, resulting in a longer service life and a higher safety factor.

Reviews

There are no reviews yet.